Essential Komatsu WA65-3/WA95-3 Wheel Loader Shop Manual (2001) (414 P.) | Pro Service File

Product Gallery

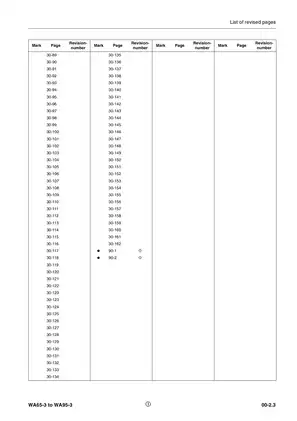

Sample pages from the Essential Komatsu WA65-3/WA95-3 Wheel Loader Shop Manual (2001) (414 P.) | Pro Service File manual

Purchase Information

Technical Specifications

- Document Number / Seller:

- 27246 / Laura King

- File Size:

- 20.70 MB

- File Type:

- ZIP

- Language:

- English

- Pages:

- 416

- Printable:

- Yes

- Estimated Download Time:

- 0.42 Minutes

- Delivery Format:

- Digital (PDF) - Instant Access

- Category:

- Wheel Loader

- Brand:

- Komatsu

- Reviewed and Approved:

- Jan 11, 2026

Komatsu Models and Parts Covered in this Wheel Loader Manual

- Komatsu WA65-3/WA95-3 Series (HA940051-HA980051 and UP) | Series: VEBM950201

- Full Coverage: Komatsu WA65-3, Komatsu WA65-3 Parallel Lift, Komatsu WA75-3, Komatsu WA85-3, Komatsu WA90-3, Komatsu WA95-3

Komatsu Propulsion Logic: Perkins or Yanmar four-cylinder diesel engine architectures utilize liquid cooling and direct injection to maintain high-torque performance frameworks. Hydrostatic Drivetrain Architectures: Variable displacement piston pumps drive high-pressure flow to a variable motor with integrated inching pedal control logic. Braking Framework Specifications: Multi-disc wet brakes operate via a master cylinder framework with independent parking brake mechanical linkage logic. Articulation Steering Logic: Central oscillating joint framework enables a 40-degree steering angle with priority valve flow distribution architectures. Operational Pressure Specifications: Main relief valve settings maintain 230 bar to 250 bar thresholds for loader lift and tilt cylinder force logic. Maintenance Clearance Framework: Cold engine valve lash adjustments require 0.20 mm intake and 0.20 mm exhaust spacing logic for optimal combustion efficiency.

Complete Manual Information

Komatsu WA65-3/WA95-3 Wheel Loader Shop Manual

Technical Applicability & Serial Ranges

- Komatsu WA65-3 (HA940051 and UP): Perkins or Yanmar 4-cylinder propulsion logic.

- Komatsu WA65-3 Parallel Lift (HA050051 and UP): Specialized loader link architectures for pallet handling.

- Komatsu WA75-3 (HA950051 and UP): Mid-size articulating framework with hydrostatic drive parameters.

- Komatsu WA85-3 (HA960051 and UP): Heavy-duty axle configurations for industrial earthmoving.

- Komatsu WA95-3 (HA980051 and UP): Maximum displacement loader with 250 bar hydraulic relief specifications.

Wheel Loader Komatsu WA65-3 through WA95-3 series units utilize a sophisticated central oscillation joint that facilitates a 40-degree steering angle while maintaining machine stability through integrated priority valve architectures. Maintaining the hydrostatic drivetrain parameters involves strict monitoring of the variable displacement piston pump output to ensure that the inching pedal control logic permits smooth transition between operational speed ranges.

Komatsu engineering prioritizes braking safety via multi-disc wet brake architectures located within the axle housing framework. These mechanical specifications ensure consistent stopping force and longevity under continuous loading cycles in varied environmental conditions.

Technical action regarding the hydraulic relief valve calibration is mandatory to maintain the 230 to 250 bar pressure thresholds required for effective lift and tilt cylinder force logic. Proper valve lash adjustment on the four-cylinder diesel engine architectures, set at 0.20 mm for both intake and exhaust valves, facilitates optimal combustion and fuel efficiency.

Engineering Intelligence & Logic

| WA65-3/WA95-3 Calibration Matrix | Specification |

|---|---|

| Main Relief Valve Pressure | 230 - 250 bar Logic |

| Steering Priority Valve Flow | Priority Distribution Logic |

| Inching Pedal Adjustment | Mechanical Linkage Parameters |

| Hydraulic Pump Charge Pressure | Piston Pump Output Logic |

| Valve Lash Clearance (Cold) | 0.20 mm Specification |

Propulsion logic for the Perkins or Yanmar diesel engines requires precise fuel injection timing to support the high-torque framework across the entire WA series. Adjusting the hydraulic charge pressure involves verifying the variable motor swash plate angle to ensure the hydrostatic drive facilitates seamless power delivery to the final drive architectures.

Diagnostic logic for the articulation joint involves checking the spherical bearing play to maintain the structural integrity of the steering framework. Mechanics must utilize the specific pressure testing ports to verify that the loader lift cylinders meet the factory-defined stroke parameters for maximum breakout force.

Operational fluid logic mandates the use of high-viscosity hydraulic oil to protect the sensitive internal components of the axial piston motor architectures. Precise calibration of the mechanical parking brake linkage ensures the machine remains stationary during service intervals, complementing the primary wet-disc braking specifications.

FAQ

Engine and drivetrain repair coverage for Komatsu WA65-3/WA95-3? 230 bar to 250 bar main relief valve pressure thresholds must be verified during loader lift and tilt cylinder force logic calibration to ensure structural integrity. This technical volume provides exhaustive data for Perkins and Yanmar four-cylinder diesel engine architectures, facilitating precise valve lash adjustments of 0.20 mm for both intake and exhaust valves. Technicians utilize the 414-page framework to troubleshoot hydrostatic drivetrain architectures, specifically checking the variable displacement piston pump output and the mechanical inching pedal linkage parameters for seamless power delivery.

Relationship between VEBM950201 and other Komatsu service volumes? Action-oriented data in the foreword specifies that for comprehensive engine overhaul logic, users must consult the Engine Shop Manual P/N YMHINSHI-H8013.

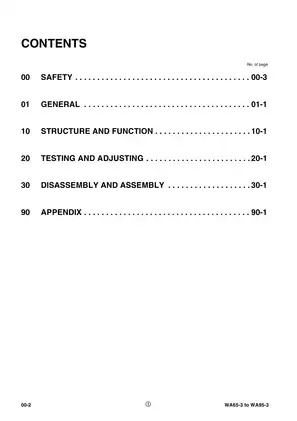

Verification of WA65-3/WA95-3 logic-framework schematic depth? 414 pages of technical data include complex wiring diagrams from Fig. 1 to Fig. 5a and exhaustive hydraulic flow architectures for the articulation steering logic.

Workshop compatibility for Komatsu WA65-3/WA95-3 print-outs? High-resolution 1:1 scale PDF schematics ensure that every priority valve flow distribution architecture remains perfectly legible on standard workshop print-outs.

Download Instructions for Komatsu Wheel Loader Manual

Frequently Asked Questions - Komatsu Wheel Loader Manual

Is this manual suitable for beginners?

Yes, this Komatsu manual is designed for both professional technicians and DIY enthusiasts. It includes step-by-step procedures with clear illustrations and safety guidelines for Wheel Loader maintenance and repair.

What file format will I receive?

You will receive this manual as a ZIP file (20.70 MB), which is compatible with all devices. The manual is fully searchable and printable for your convenience.

How quickly can I access the manual after purchase?

You'll receive instant access to your Komatsu Wheel Loader manual immediately after payment completion. The download link is valid for 3 days, with lifetime re-download guarantee.

Can I print specific sections of the manual?

Absolutely! This digital manual allows you to print any section you need, from individual pages to complete chapters, making it perfect for workshop use.

Customer Reviews and Feedback

Read what our customers say about this Komatsu Wheel Loader manual and share your own experience.

Add Comment

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Comments (3)