2007-2008 Kawasaki Ultra 250X Service Manual

This Service Manual provides diagnostic procedures, removal sequences, and maintenance for the Kawasaki Ultra 250X: fuel system, engine lubrication, exhaust, and top end. Part 92110-1145.

Manual Preview

Sample pages from the 2007-2008 Kawasaki Ultra 250X Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kawasaki Ultra 250X (JT1500, JT1500B) – 2007-2008 Diagnostic procedures and component service for... Kawasaki Jet Ski Ultra 250X, JT1500, JT1500B service manual, 2007-2008 edition Engine Type: 4-stroke, DOHC, 4-cylinder, water cooled Displacement: 1498 cm³ (91.4 cu in.) Max Horsepower: 184 kW (250 PS) @7 750 r/min Max Torque: 237 N·m (24.2 kgf·m, 174.8 ft·lb) @6 500 r/min Fuel Tank Capacity: 78 L (20.6 US gal) Overall Length: 3370 mm (132.7 in.)

Professional Workshop Service Manual & Technical Specifications

Kawasaki Jet Ski Ultra 250X, JT1500, JT1500B Service Manual: 2007-2008 edition Technical-Guide

Reference-Category: Jet Ski / Kawasaki Specification-Class: Watercraft / Marine Reference-Category: Manual

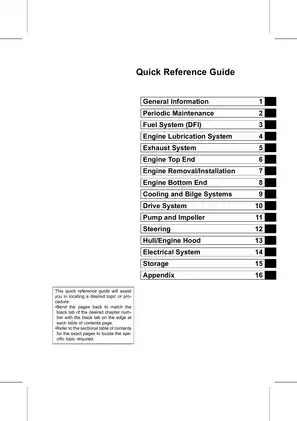

Table of Contents

- General Information

- Periodic Maintenance

- Fuel System (DFI)

- Engine Lubrication System

- Exhaust System

- Engine Top End

Coverage is segmented into sections detailing the watercraft's systems. This manual outlines procedures for inspection, removal, installation, and troubleshooting of various components. It includes specifications, special tools, and torque values necessary for proper maintenance and repair.

Component locations are identified for

Diagnostic procedures for the DFI system, including self-diagnosis and troubleshooting for sensors and actuators. The manual details the system's wiring diagrams and component test procedures.

Service procedures are documented for

Engine lubrication systems, covering oil level checks, oil and filter changes, oil cooler maintenance, and oil pump assembly. It also details specifications for engine oil and oil pressure measurements.

Calibration requirements are specified for

The exhaust system, including manifold, pipe, and muffler body removal and installation. It also covers water box muffler inspection and maintenance.

Electrical system documentation covers

Engine top end components, such as cylinder head covers, camshafts, tensioners, cylinder heads, and valves. It provides detailed specifications for valve clearance and piston measurements.

Suspension service documentation covers

Special tools and sealants required for various procedures, including compression gauges, valve seat cutters, and ring compressors. This ensures the correct tools are used for accurate repairs.

...documents torque specifications for fasteners to ensure proper fastener fatigue prevention.

FAQ

Customer Reviews

Read what our customers say about this Kawasaki Jet Ski manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)