John Deere PowerTech E 2.4L & 3.0L Diesel Engines 2007 Technical Manual

This technical manual provides comprehensive service and repair information for John Deere PowerTech E 2.4L and 3.0L diesel engines, covering all aspects of maintenance and troubleshooting. Ref: CTM301

Manual Preview

Sample pages from the John Deere PowerTech E 2.4L & 3.0L Diesel Engines 2007 Technical Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Consolidated Shop Reference Manual: John Deere PowerTech E™ 2.4L and 3.0L Diesel Engines (2007) - Factory Service Manual & Troubleshooting Technical-Repository | John Deere PowerTech E™ 2.4L and 3.0L Diesel Engines (2007) | Component Technical Manual.

Engine Specifications:

- Engine Displacement Data: 2.4 L and 3.0 L displacement values are standard for engine operation.

- Fuel Type Standards: Diesel fuels specified to EN 590 or ASTM D975 are recommended for optimal performance.

- Injection System Components: Unit injection pump and nozzle assemblies are used for precise fuel delivery.

- Turbocharger Specifications: Equipped with turbochargers for increased power and cleaner emissions.

- Cooling System Capacity: Features a pressurized cooling system with radiator, water pump, and thermostat.

- Lubrication System Components: Driven by a crankshaft-mounted gerotor oil pump for efficient lubrication.

Professional Workshop Service Manual & Technical Specifications

Consolidated Shop Reference Manual: John Deere PowerTech E™ 2.4L and 3.0L Diesel Engines (2007) - Factory Service Manual & Troubleshooting Technical-Repository

Application-Range: John Deere PowerTech E™ 2.4L and 3.0L Diesel Engines (2007) // Operational-Framework: Diesel Engine // Assembly-Group: Fuel System.

Professionally establishing the operational framework for John Deere PowerTech E™ engines, this manual outlines critical maintenance and repair procedures. It details the complex interplay of systems, from base engine operation to specialized fuel and lubrication services, ensuring optimal performance and longevity.

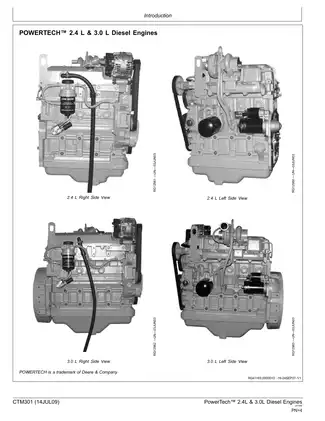

Base Engine Operation

This section provides a foundational understanding of the engine's core functions, including cylinder block design, crankshaft mechanisms, piston assemblies, and valve actuation via hydraulic lifters. It covers the Series 250 engine's vertical, inline configuration and its key components like the turbocharger and unit injector system.

Fuel System

The manual details the Series 250 fuel system, highlighting the integral pumping unit and nozzle assembly. It explains the role of the fuel transfer pump, filter, and mechanical governor in precise fuel delivery and injection timing.

Lubrication System

This part covers the engine's lubrication system, from the crankshaft-driven gerotor oil pump to the oil filter, oil cooler, and pressure regulating valve, ensuring efficient oil circulation and component protection.

Cooling System

It describes the pressurized cooling system, including the radiator, water pump, thermostat, and housing, crucial for maintaining optimal engine operating temperatures.

Table

| Performance-Element | Technical-Path | Calibration-Spec |

|---|---|---|

| Engine Specifications | Component Overviews | Assembly Procedures |

| Fuel Delivery | Injection Timing | Pump Calibration |

| Lubrication Flow | Oil Pressure | Filter Replacement |

| Cooling Efficiency | Temperature Regulation | Coolant Mixture |

| Air Intake | Turbocharger | Exhaust System |

| System Diagnostics | Troubleshooting | Component Testing |

Specifications

This manual includes detailed specifications for all engine components, ensuring that all repair and maintenance procedures are performed to factory standards, covering critical aspects like clearances, torques, and material tolerances.

FAQ

Customer Reviews

Read what our customers say about this John Deere Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)