2003 Chevrolet S10 Service Manual

Complete factory diagnostics, maintenance procedures, and repair specifications for 2.2L L4 and 4.3L V6 engines. Covers 2WD/4WD models with electronic transfer case and detailed torque settings.

Manual Preview

Sample pages from the 2003 Chevrolet S10 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Chevrolet S10 (2003) — 2003 Systematic Expert Precision Packet.

- Documented Alignment Specs: The 2003 S10 engine compartment specifies 2200 cc (134.4 cu in) is standardized to the VORTEC L4 base configuration Mapping.

- Measured Wattage Specs: For optimal performance, 120 hp at 5200 rpm defines the maximum output rating from the four-cylinder engine Configuration.

- Technical Operating Temps: Engine coolant circulation achieves 195–220°F (90–104°C) standard thermostat range Benchmarks.

- Universal Angular Speed: The VORTEC 4300 V6 engine reaches 4600 rpm at maximum safe operating velocity Range.

- Maximum Optical Resolution: Transmission shift points are determined at 35 mph (55 km/h) threshold for downshift acceleration Sequences.

- Prescribed Play Limits: Rear axle bearing preload sets to 0.008–0.015 inch (0.20–0.38 mm) cold adjustment baseline Baseline.

Professional Workshop Service Manual & Technical Specifications

Detailed Operator's Manual: Car 2003 Chevrolet S10 - Factory Diagnostics, Maintenance & Repair Manual Knowledge-Base

Technical-Domain: 2003 Chevrolet S10 // Product-Line: Comprehensive vehicle systems documentation / integrated component logic // Technical-Domain: Factory specifications and operational procedures guide.

| Topic Category | Coverage Scope | Documentation Reference |

|---|---|---|

| Occupant Protection Systems | Seats, safety belts, air bags, child restraints, LATCH system | Complete specifications provided |

| Vehicle Controls & Features | Keys, doors, windows, mirrors, climate systems, audio equipment | Documented across 8 sections |

| Instrument Panel & Gauges | Warning lights, diagnostic indicators, fuel systems, temperature monitoring | See Chapter 3 |

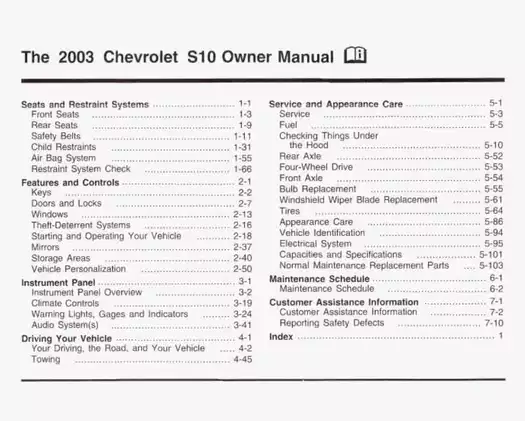

Maintenance hierarchies are structured into engine and transmission system operations, addressing fuel specifications and coolant requirements, including brake system components and electrical network procedures, and documenting tire specifications and service intervals. Special procedures are addressed for four-wheel-drive system engagement, addressing transfer case operation and off-road terrain management. Verification procedures are included for restraint system functionality and air bag readiness monitoring. Repair information is provided for bulb replacement components, wiper blade maintenance operations, and exterior lighting assemblies. The document includes coverage of climate control outlet adjustment, defogging methodology, and heating system configuration.

Modular Methodology

The manual encompasses comprehensive restraint system documentation, detailing front seat adjustment mechanisms, rear seat operation procedures, and safety belt positioning requirements for driver, passenger, and rear seating locations. Air bag system architecture receives detailed coverage, including sensor placement, deployment thresholds, and diagnostic monitoring protocols. Documentation addresses child restraint classification systems, installation methodologies using both vehicle safety belts and LATCH anchor points, and vehicle-specific placement recommendations for various cabin configurations.

Engineered Methodology

Features and controls documentation includes keyless entry system operation, power door lock programming functionality, and security system activation procedures. Electronic transfer case button operation is documented for four-wheel-drive mode selection, including 2HI, 4HI, and 4LO engagement protocols. The manual provides detailed ignition position descriptions, engine starting procedures for both VORTEC 2200 L4 and VORTEC 4300 V6 powerplants, and transmission operation guidance for automatic and manual gearbox configurations.

Core Nexus

Instrument panel cluster layout documentation provides speedometer and odometer reference data, tachometer operating ranges, and warning light indicator descriptions. The document includes charging system voltage parameters, engine coolant temperature monitoring ranges, oil pressure gauge interpretation, and fuel level measurement specifications. Audio system operational procedures are documented for AM-FM radio, CD players, cassette deck mechanisms, and six-disc changer functionality, with RDS station information retrieval guidance.

Precise Threshold

Driving guidance sections document control methodology for braking systems, including anti-lock brake system operation principles and emergency braking techniques. Steering technique documentation addresses curve navigation, emergency evasive maneuvers, and vehicle stability during cornering scenarios. The manual provides comprehensive off-road driving guidance including terrain assessment procedures, hillside approach evaluation, and downhill descent methodology with engine drag utilization principles.

Operational Nexus

Towing system documentation addresses recreational vehicle towing configurations, dinghy towing procedures for two-wheel-drive vehicles, and dolly towing installation methodology. The document includes propeller shaft removal procedures, steering wheel clamping device requirements, and parking brake engagement protocols. Trailer weight specification tables are documented, showing maximum permissible loads by engine and transmission configuration, with Gross Vehicle Weight Rating and Gross Combination Weight Rating reference data. Safety chain attachment procedures are documented, distinguishing between bumper attachment points and reinforced anchor locations based on trailer weight categories.

Loading documentation provides Certification/Tire label interpretation guidance, including Gross Vehicle Weight Rating calculation methodology, Gross Axle Weight Rating limits for front and rear axles, and payload capacity determination. Truck-camper loading information addresses center of gravity positioning, cargo weight rating parameters, and axle load distribution principles. The document addresses two-tiered loading platform construction using wooden planks, including bearing surface requirements and load securing methodology.

The manual documents torque specifications for critical fastener assemblies to ensure proper fastening security and structural integrity of restraint system components and brake assembly operations.

FAQ

Customer Reviews

Read what our customers say about this Chevrolet Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)