1999 New Holland W110/W130/LW110/LW130 Wheel Loader Service Manual (334 P.)

Complete service documentation for New Holland Construction wheel loaders with Fiat diesel engines. Covers transmission, braking system, and hydraulic equipment controls. Reference PN 75131007, March 1999.

Manual Preview

Sample pages from the 1999 New Holland W110/W130/LW110/LW130 Wheel Loader Service Manual (334 P.) manual

Purchase & Download

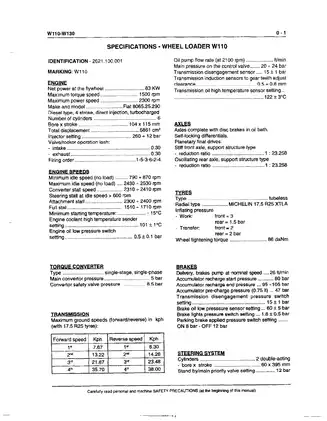

Models Covered & Key Technical Specifications

New Holland W110, W130, LW110 & LW130 — 1999 Specialized Dossier Binder | Wheel Loader Collection.

- Measured Scan Resolution: 1200 × 1200 dpi is standardized to the scanner output Architecture.

- Fundamental Tightening Data: For optimal performance, 86 daNm (627 ft-lbs) determines the wheel nut fastening Threshold.

- Baseline Storage Capacity: The fuel reservoir is calibrated to 170 L (44.9 US gal) total volume Mapping.

- Integral Electrical Specs: Operating voltage is rated at 24 V DC with dual maintenance-free batteries (2 × 100 Ah) Configuration.

- Operational Thermal Rating: Engine coolant maximum temperature achieves 101°C ± 1°C sensor setting Benchmarks.

- Published Addressable Resolution: Transmission oil temperature sensor corresponds to 122°C ± 3°C high-temperature activation Range.

Professional Workshop Service Manual & Technical Specifications

Unified Technical Manual: New Holland W110, W130, LW110 & LW130 Wheel Loader Service-Dossier

Documentation-Type: W110 (1999), W130 (1999), LW110 (1999), LW130 (1999) // Engine-Type: Fiat 8065.25.290 & 8065.25.291, 6-Cylinder Turbocharged Diesel / Direct Injection Systems // Serial-Range: Complete specifications for torque converter, transmission control systems, and planetary final reduction units.

| Document Section | Coverage Summary | Reference Material |

|---|---|---|

| Engine Systems | Fuel injection pump settings, turbocharger operation, cooling and lubrication circuits | Bosch injection, GARRET TO48 turbo, timing specifications documented |

| Transmission & Drivetrain | Torque converter assembly, 4-speed automatic transmission, differential operation | Hydraulic clutch engagement pressures, control valve diagrams provided |

| Brake Systems | Disc brake operation, accumulator settings, parking brake control | Accumulator precharge specifications included |

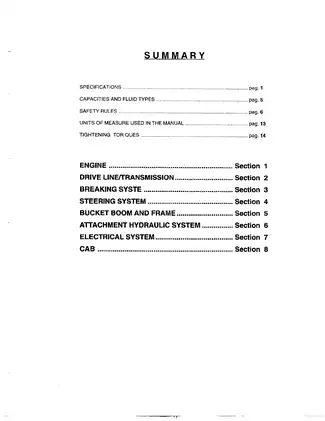

Organized into dedicated modules for engine assembly and maintenance, the document includes detailed sections on transmission control valve operation with solenoid function tables, comprehensive coverage of front and rear axle reduction gears with bearing adjustment procedures, and complete steering system documentation featuring priority valve operation and emergency steering pump configuration. The manual provides comprehensive reference data for coolant temperatures and transmission oil heat exchanger specifications, documents tightening torque values for main transmission bolts and engine support brackets, and establishes the complete functional sequence of load sensing hydraulic controls for equipment operation.

Technically establishing proper service procedures, the description encompasses lubrication system principles with gear pump specifications, detailed air intake and turbocharger maintenance data, complete electrical system diagrams with connector reference points, and comprehensive brake system schematics. The service manual documents torque specifications for planetary carrier mounting bolts to ensure proper final drive assembly contact, includes differential backlash adjustment tables with measurement procedures, and provides complete cooling system water pump operation documentation. Reference material captures rocker arm lash specifications for valve train adjustment, documents accumulator precharge nitrogen pressure settings at specified temperatures, and includes complete parking brake engagement test procedures with manual release instructions.

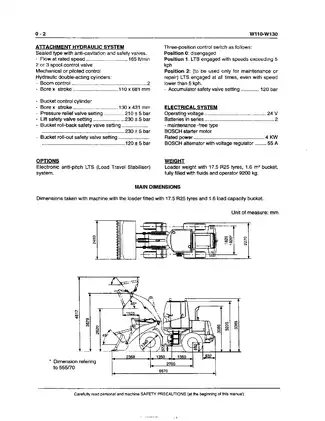

The document contains extensive hydraulic circuit schematics for both steering and equipment control systems, detailed disassembly and reassembly procedures for transmission clutch shafts with component removal sequences, complete specifications for hydraulic pump flow rates and pressure relief valve settings, and comprehensive wiring diagrams for the 24-volt electrical system with solenoid valve function tables. The manual includes detailed cab component documentation covering windshield wiper systems, heater operation and maintenance, and glass replacement procedures using polyurethane bonding adhesive. Technical sections address frame articulation pivot pin specifications, load handling system linkage geometry, and bucket cylinder bore and stroke measurements for both standard and high-capacity configurations.

FAQ

Customer Reviews

Read what our customers say about this New Holland Wheel Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)