1999 New Holland LS190 Skid Steer Loader Service Manual (148 P.)

450/NC engine specs, hydrostatic transmission maintenance, boom/bucket hydraulics, and troubleshooting for LS190/Lx985 models. NH filter #9842392 and essential operator guidance.

Manual Preview

Sample pages from the 1999 New Holland LS190 Skid Steer Loader Service Manual (148 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland LS190 (86589933) — 1999 Documentary Directory Binder.

- Authorized Fastener Specs: 304 cu.in. (5 L) is set to the engine cylinder volume Benchmarks.

- Critical Reservoir Specs: For optimal hydraulic operation, 11.3 gal. (42.6 L) specifies the system capacity Range.

- Operational Spacing Data: The boom cylinders at 2.75² (7.0 cm) bore — yields maximum lifting pressure Sequences.

- Established Electrical Load: The battery reaches (2) BCI 35/75 units rated at 625 amps cold cranking capacity Baseline.

- Measured Production Rate: Operating at 2325–2375 RPM produces 75 SAE net horsepower and 240 ft. lbs. (325 N·m) torque Requirements.

- Maximum Securement Values: Travel speeds in low range achieve 7.6 MPH (12.2 KPH) and high range reaches 12 MPH (19.3 KPH) Threshold.

Professional Workshop Service Manual & Technical Specifications

Essential Safety Field Manual: New Holland LS190 Skid Steer Loader 1999 Information-Suite

Operational-Framework: Covers LS190 and LX985 models (1999) // Component-Focus: Engine, transmission and hydraulic system documentation / Loader operation reference // Engine-Type: 450/NC diesel, 75 SAE net HP, four-cylinder configuration.

| Integrated-Framework | Operational-Logic | Architecture |

|---|---|---|

| Engine Documentation | Specifications and performance data | 450/NC diesel engine (75 HP net, 304 cubic inches) |

| Hydraulic Systems | Control valve operation and pressure settings | Variable displacement piston pumps/motors; 20 GPM standard flow |

| Transmission Control | Hydrostatic drive linkage and adjustment procedures | Two-speed variable motor system; high/low range capability |

| Boom/Bucket Mechanisms | Lift cylinder specifications and control options | Double-acting cylinders; foot and hand control configurations |

| Electrical Monitoring | Advanced Warning System (EIC) sensor documentation | Electronic Instrument Cluster with fault detection and safety interlocks |

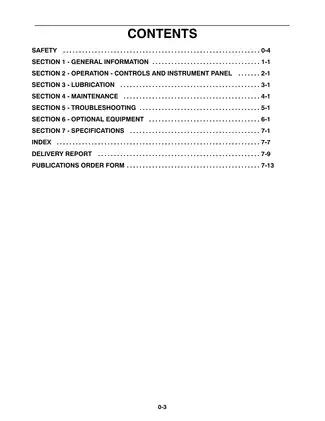

The documentation provides guidance on General Information including model identification, operator seat adjustment, boom locking mechanisms, and prestarting checklists that verify proper operation of all controls. Within the manual's extensive coverage, Operation sections document Electronic Instrument Cluster functions with fuel gauge display and automatic shutdown features, and Lubrication procedures reference maintenance intervals for engine crankcase, hydraulic systems, and final drive components. The document includes detailed Troubleshooting guidance addressing EIC interlock circuits and hydraulic system diagnostics, while Specifications chapters deliver comprehensive performance data and dimensional reference materials. Additionally, the manual encompasses Optional Equipment descriptions covering bucket types, tire configurations, hydraulic attachments, and cab enclosure systems. The narrative sequence advances from fundamental control operation through complex hydrostatic transmission adjustment, establishing systematic progression for users requiring both operational competency and mechanical understanding.

Verification procedures are included for Electronic Instrument Cluster monitoring of coolant temperature, oil pressure, and battery voltage status to maintain proper engine function. Repair information is provided for boom and bucket hydraulic systems, including control linkage adjustments and spring tension procedures for neutral positioning. The document includes coverage of transmission charge pressure monitoring, filter condition assessment through the EIC visual display system, and fault code identification for electrical circuit malfunctions. Brake system specifications are included for the parking brake linkage assembly with detailed adjustment methodology to ensure proper engagement force and release characteristics. Safety procedures are documented for cab tilting operations, which require proper jack installation, boom lock pin engagement, and sequential bolt removal/reinstallation to prevent structural damage during major component service.

The manual documents torque specifications for critical fasteners to ensure proper joint separation prevention. Wheel lug torque (125 ft-lbs), cab mounting bolts (80-160 ft-lbs), and final drive axle hardware (140 ft-lbs) are referenced throughout the maintenance sections. Technical specifications table details the complete engine configuration with compression ratio (17.5:1), valve clearance measurements, and fuel injection specifications. Additional reference data encompasses bucket capacity ranges (12.2-22.3 cubic feet struck volume), tire pressure requirements (50-60 PSI depending on tread type), and material weight classifications for load-matching guidance.

FAQ

Customer Reviews

Read what our customers say about this New Holland Skid Steer Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)