2006 New Holland LS180.B/LS185.B/LS190.B Repair Manual (837 P.)

Complete repair documentation for LS-series skid steers — hydraulic systems, engine, transmission, and chassis assemblies with factory torque specifications and service procedures.

Manual Preview

Sample pages from the 2006 New Holland LS180.B/LS185.B/LS190.B Repair Manual (837 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland LS180.B, LS185.B, LS190.B — 2006 Systematic Manufacturer Blueprint | Skid Steer Loader Repository.

-

Reference Velocity Specs: The hydrostatic pump displacement reaches 46 cc (2.81 in³) per revolution is set to the tandem axial piston architecture Requirements.

-

Integral Component Weight: For maximum horsepower output, the LS190.B engine specifies 60 kW (80.5 hp) gross bare engine rating Framework.

-

General Addressable Resolution: The diesel fuel tank capacity yields 81.4 L (21.5 US gal) for the LS190.B, LS185.B and LT190.B machine configuration Mapping.

-

Essential Reservoir Specs: The primary hydraulic system reaches 57 L (14.8 US gal) total capacity — established for full operational requirements Threshold.

-

Baseline Interference Fit: The drive motor maximum displacement dictates 470 cc (28.7 in³) at rated engine RPM for single speed and 2 speed operation Benchmarks.

-

Established Feed Speed: System relief valve pressure produces 20,498 kPa (205 bar) at 2300 rpm — specified as the main relief pressure control Range.

Professional Workshop Service Manual & Technical Specifications

Industrial Configuration Manual: Skid Steer Loader New Holland LS180.B, LS185.B, LS190.B 2006 - Comprehensive Repair & Maintenance Manual Engineering-Archive

Engine-Type: LS180.B (2006), LS185.B (2006), LS190.B (2006), LT185.B (2006), LT190.B (2006) // Repair-Classification: Distribution, Power Production, Transmission, Traveling Systems Logic // Application-Range: Skid Steer Loader Service and Technical Documentation.

| Performance-Element | Baseline | Architecture |

|---|---|---|

| Total Document Pages | 837 pages, 57.08 MB | Complete service manual with ICE coding system |

| Hydraulic Systems | Primary, Secondary, High-Flow circuits | Detailed schematics and component specifications |

| Engine Specifications | Family III diesel engines (3 and 4-cylinder) | Technical data for three model variants |

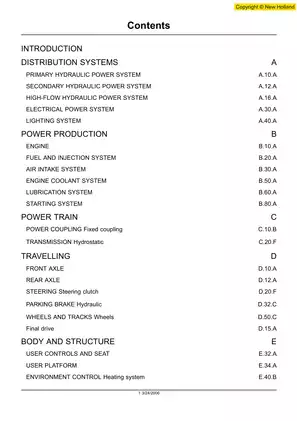

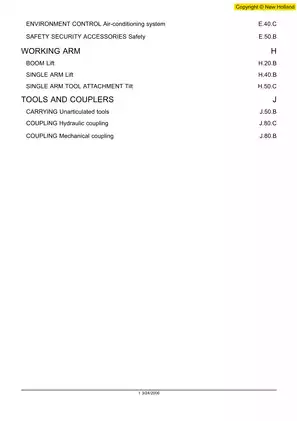

Diagnostic procedures address the systematic organization of this comprehensive reference through seven primary sections covering distribution systems, power production, power train, and traveling components. OEM specifications cover engine ratings, hydraulic displacement values, torque capacities, and system relief pressures across all model configurations. The document provides detailed information addressing primary hydraulic power systems (including pump specifications, relief valve settings, and charge pressure documentation), secondary hydraulic circuits, and high-flow hydraulic system layouts with component identification.

System operation descriptions cover engine and transmission functions, detailing both three-cylinder naturally aspirated and turbocharged engines alongside four-cylinder variants with specifications for bore, stroke, displacement, compression ratios, and power output ratings. The documentation addresses fuel and injection systems, air intake assemblies, engine coolant pathways, and lubrication system specifications. Assembly instructions are detailed for starting systems, electrical power distribution, alternator and battery configurations, and complete wiring harness identification through twenty-seven electrical schematic frames.

Hydraulic schematics are included for primary and secondary power systems presenting pump configurations, motor circuits, control valve assemblies, relief valve locations, and auxiliary system layouts. Steering component information is provided for hydrostatic transmission controls, servo piston adjustment procedures, and steering clutch assembly documentation. The manual documents torque specifications for bolt fasteners to ensure proper assembly stress control, with comprehensive tables for metric and decimal hardware across multiple grades and sizes.

The document includes chapters on power coupling, fixed coupling design, transmission hydrostatic systems with tandem axial piston pump specifications and radial piston drive motor configurations, traveling systems encompassing front and rear axles, final drive mechanisms, wheels and tracks, and parking brake hydraulic assemblies. Lighting system documentation covers marker lights, turn signals, beacons, work lights, and road lighting configurations specific to standard and European model variants.

Summary of Document Contents: The introduction and reference materials present conversion factors and torque specifications including bolt grades, hydraulic fitting torques, and pipe fitting pressure ratings. Distribution systems sections detail primary, secondary, and high-flow hydraulic power systems with complete electrical power and lighting documentation. Power production sections reference engine specifications, fuel system particulars, air intake documentation, engine coolant requirements, and starting system assembly details. Power train information encompasses power coupling configuration, hydrostatic transmission pump and motor disassembly procedures, servo control adjustments, and relief valve pressure testing. Traveling sections address front and rear axle assemblies, steering and parking brake systems, plus wheels and final drive components.

Methodically calling for systematic component maintenance, this technical manual provides complete reference data for service technicians requiring specifications, wiring diagrams, hydraulic schematics, torque values, and disassembly-assembly procedures across all major machine systems.

FAQ

Customer Reviews

Read what our customers say about this New Holland Skid Steer Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)