2000 New Holland DC70/DC80/DC100 Dozer Service Manual (307 P.)

2000 New Holland dozer lineup — Cummins turbocharged diesel engine, hydrostatic transmission, sealed track drive, and blade hydraulic control. Complete shop service documentation with specifications, repair procedures, and parts identification for heavy construction grading equipment.

Manual Preview

Sample pages from the 2000 New Holland DC70/DC80/DC100 Dozer Service Manual (307 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland DC70/DC80/DC100 Dozer Series — 2000 Technical Reference Unit | Construction Dozer Collection.

- Verified Reservoir Specs: For hydraulic operation, 85 L (22.4 gal) represents the equipment fluid storage volume Architecture.

- Calibrated Displacement Data: 3920 cm³ (239.1 in³) is specified as the engine cylinder volume Specification.

- Key Torque Rating: Maximum transmission output reaches 44.5 daNm (322 lb-ft) at 1500 rev/min Framework.

- Principal Pressure Data: 430 bar (6,236 PSI) — is rated at the hydrostatic transmission operating envelope Norms.

- Advanced Pump Capacity: The equipment gear pump requires 54 l/min (14.26 gal/min) for full system function Bounds.

- Designated Battery Specification: Storage capacity reaches 180 Ah (ampere-hour) at 12 V power level Topology.

Professional Workshop Service Manual & Technical Specifications

Strategic Configuration Reference Manual: New Holland DC70/DC80/DC100 Dozer Service Manual (2000) 392 Page Volume | Shop Standards Technical-Guide

Reference-Category: New Holland DC70, DC70 LGP, DC80, DC80 LGP, DC100, DC100 LGP // Operational-Framework: Hydrostatic transmission with closed-circuit control systems / Sealed and lubricated track undercarriage Logic // Design-Core: Four-cylinder turbocharged diesel engines with pilot-operated hydraulic systems.

| Assessment-Parameter | System-Path | Calibration-Spec |

|---|---|---|

| Engine Architecture | Cummins four-cylinder liquid-cooled diesel with induction turbocharging | Specifications documented for DC70, DC80, DC100 variants |

| Transmission System | Dual variable displacement pump and motor hydrostatic design | Operating pressures and flow capacities documented |

| Track Assembly | Sealed and lubricated split-master link chains with permanently lubricated rollers | Ground contact area and tension specifications included |

| Blade Control | Load-sensing pilot control with adjustable tilt and angle cylinder functions | Cylinder dimensions and range of motion data provided |

| Lubrication Requirements | Multi-grade diesel engine oil, gear oil for final drives, hydraulic fluid for circuits | SAE specifications and viscosity ranges documented |

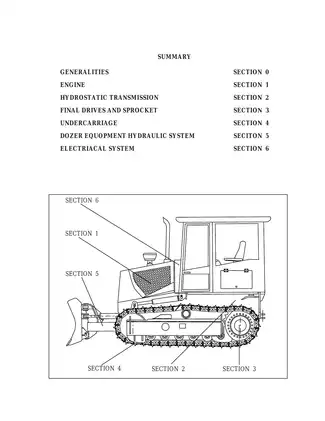

Diagnostic procedures address engine and transmission systems, undercarriage inspection protocols, hydraulic circuit testing, and electrical component verification. Reference data is included for hydrostatic transmission pressures, engine fuel injection timing, final drive reduction ratios, and track chain pitch measurements. Blade positioning data includes cutting angle ranges, lifting height limits, and moldboard volume specifications for each model variant.

Hydraulic schematics are included for the transmission pump and motor assemblies, servocontrol valve circuits, and equipment hydraulic systems controlling blade functions. Steering component information is provided for the joystick control mechanisms, proportional pressure reduction valves, and directional control solenoids. Inspection guidelines are provided for track idler wheel bushings, bottom roller seals, carrier roller bearings, and sprocket tooth wear patterns. Alignment specifications are included for transmission control elements, pump displacement settings, and final drive gear engagement parameters. Reference data is included for fuel consumption rates, hydraulic pressure settings, torque converter oil levels, and coolant capacity requirements.

The manual documents torque specifications for the transmission pump and final drive assemblies to ensure proper axial load stability. Wiring diagrams illustrate the control panel circuits, solenoid valve activation sequences, microprocessor input signals, and warning light logic. Component specifications address the four-cylinder Cummins engine displacement, the hydrostatic transmission pump displacement range, final drive reduction gear ratios, blade cutting edge material composition, and track chain link dimensions across all model variants.

Disassembly and reassembly procedures are presented for transmission pumps, motors, final drives, track suspension components, and blade control cylinders. The document includes detailed inspection tables for measuring wear on sprocket teeth, idler wheel diameter reduction, bottom roller bushing clearance, and track chain pitch elongation. Lubrication procedures address sealed roller maintenance, track adjuster hydraulic pressure settings, blade hinge lubrication intervals, and transmission fluid cooling system operation.

FAQ

Customer Reviews

Read what our customers say about this New Holland Dozer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)