1999 New Holland LB 75 Backhoe Loader Operation and Maintenance Manual (196 P.)

Documents LB 75 service procedures, loader and backhoe operation, lubrication schedules. Covers transmission, hydraulic systems, and field operations. Reference manual 86594261.

Manual Preview

Sample pages from the 1999 New Holland LB 75 Backhoe Loader Operation and Maintenance Manual (196 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland LB 75 Backhoe Loader (86594261) — 1999 Professional Reference Sourcebook | LB 75 Series Module.

- Certified Voltage Specs: The alternator produces 65 amperes is measured at maximum electrical output Architecture.

- Measured Thermal Limits: For optimal engine cooling, 79°C (174°F) represents the thermostat opening point Norms.

- Defined Throughput Data: Hydraulic pump capacity reaches 78.2 liters/min (20.6 gal/min) at 2300 rpm Bounds.

- Key Gross Dimensions: The engine displacement requires 3908 cm³ (238 cu in) for the combustion chamber Topology.

- Primary Rotational Force: Maximum torque is configured at 275 N·m (200 lbf-ft) at 1400 rev/min Matrix.

- Baseline Energy Draw: Rated horsepower achieves 51.5 kW (70 hp) at standard operating conditions Standards.

Professional Workshop Service Manual & Technical Specifications

Industrial Factory Diagnostic Manual: Backhoe Loader New Holland LB 75 1999 - Comprehensive Operations & Maintenance Manual Service-Dossier

Equipment-Series: New Holland LB 75 Backhoe Loader (1999 model) // Design-Core: Dual-function loader and excavation system with hydraulic operation // Conceptual-Layout: 196-page comprehensive reference documenting complete machine operation, control systems, and service procedures.

| Identifier | Value | Calibration-Standards |

|---|---|---|

| Engine Type | IVECO 8045.05B Diesel | Engine specifications documented in Section 8 |

| Transmission | Power Shuttle 4×4 with four forward/reverse gears | Transmission control procedures in Section 2 |

| Hydraulic System | Dual pump with loader and backhoe circuits | Pressure relief settings and capacities documented |

| Operating Weight | 6,355 kg base configuration | Varies with attachments and ballast options |

| Rated Horsepower | 70 HP (51.5 kW) at 2,300 rev/min | Engine performance specifications provided |

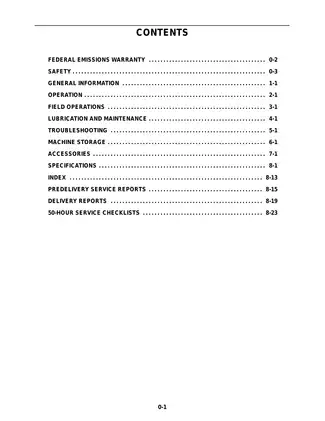

Safely mandating operator familiarity with comprehensive machine documentation, this 196-page manual provides a structural breakdown of the backhoe loader's complete operational framework. The document encompasses fourteen major sections addressing everything from general information and control systems through field operations, maintenance schedules, troubleshooting procedures, and storage protocols. Coverage is segmented into distinct functional areas—each designed to address specific operational requirements or maintenance intervals.

The manual documents detailed cab controls and instrumentation, including the power shuttle transmission with its forward/reverse shuttle lever, transmission disconnect switches, and independent brake pedals with latch mechanisms for highway operation. Loader lever shift patterns are comprehensively illustrated for both standard and optional multi-purpose bucket configurations, while backhoe control patterns are presented in standard, four-lever, and ISO variations. The document addresses hydraulic system architecture, detailing loader arm float positions, bucket roll-back functions, and the optional hydraulic extendible dipper extension system.

Quality checks are addressed for the stabilizer lever operation, which requires lowering to ground prior to backhoe work, along with guidance on swing frame clamping for sideshift models. The troubleshooting chapter addresses engine starting difficulties, transmission operation concerns, electrical system malfunctions, brake performance issues, and environmental factors affecting cab comfort. Cooling system maintenance is addressed in the lubrication section, which documents torque specifications for the IVECO engine to ensure proper vibration dampening.

Testing requirements are specified for the four-wheel drive engagement system, differential lock pedal operation, and power shuttle transmission shuttle lever transitions between forward and reverse travel. The manual documents torque specifications for the [component] to ensure proper vibration dampening. The document includes complete specifications tables for loader bucket performance (breakout force 6,010 kg, maximum reach 0.75 m fully raised), backhoe digging depth data (4.36 m standard dipper, 5.58 m with extendible dipper option), and stabilizer spread measurements across transport and working configurations.

| Documented Content Area | Coverage | Reference Chapter |

|---|---|---|

| Loader operations and attachment procedures | Complete procedures for standard, multipurpose, and optional fork configurations | Section 3 |

| Backhoe trenching and lift applications | Operating techniques for excavation, material handling, and load lifting | Section 3 |

| Maintenance intervals and lubrication points | Service schedule from 50-hour through 1,200-hour intervals | Section 4 |

| Troubleshooting diagnostic tables | Engine, transmission, electrical, brake, and cab system problem identification | Section 5 |

| Storage and seasonal operation | Pre-storage preparation and post-storage startup procedures | Sections 3, 6 |

The manual provides extensive guidance on the running-in procedure during the initial 50-hour service period, detailing daily checks including radiator coolant level, engine oil level, hydraulic system oil level, transmission oil level, and rear axle oil verification. It documents air cleaner restriction indicators, fuel system water separator maintenance, battery electrolyte monitoring, and the protocol for the factory-recommended 50-hour service checkpoint. Loader and backhoe lubrication fittings are mapped throughout the document, with specific intervals noted for greasing door hinges, differential lock linkage, front axle trunnion bearings, and swing cylinder attachment points.

The hydraulic system section details dual pump operation (78.2 liters per minute per pump at rated speed), main relief valve settings at 197 bar for the front pump, and circuit-specific relief valves ranging from 160 bar on the bucket cylinder rod end to 317 bar on the backhoe lift cylinder. The transmission disconnect feature is documented to allow gear changes on the move while maintaining transmission pressure, with specific warnings regarding clutch slip prevention during low-speed inching. Special attention is given to the hydrostatic power steering system operating at 140 bar, noting that the steering wheel must never be held against the stops to prevent system component damage.

Safety decals and warning systems are comprehensively documented with specific part numbers and mounting locations, including loader arm support warnings, air conditioning refrigerant hazard information, and electrical safety protocols for jump-starting procedures. The document includes complete identification plate locations for vehicle serial numbers, engine model and serial identification, four-wheel drive axle type and ratio data, transmission model and serial information, rear axle identification, and cab/ROPS certification plates. Environmental considerations are addressed regarding fuel storage, oil disposal, coolant handling, and compliance with local regulations for emissions control system maintenance.

The manual presents tire pressure and load tables for both two-wheel and four-wheel drive configurations, with inflation pressure guidance ranging from 1.5 to 3.9 bar for front tires and detailed rear tire capacity specifications. Ballasting recommendations include liquid calcium chloride solutions providing freeze protection to -46°C, with specific fill quantities for tire sizes ranging from 11L-16 front tires to 19.5L-24 rear industrial tires. Road speed tables demonstrate ground speeds from 5.3 km/h in first gear forward to 38.3 km/h in fourth gear reverse when equipped with 19.5L-24 tires at 2,300 rev/min engine speed.

FAQ

Customer Reviews

Read what our customers say about this New Holland Backhoe Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)