2004 John Deere 444J, 544J, 624J Loader Repair Technical Manual

Technician-level documentation for 444J, 544J, 624J Loaders: engine, axles, transmission, hydraulics, steering, and more. Includes detailed procedures and specifications. P/N TM2136

Manual Preview

Sample pages from the 2004 John Deere 444J, 544J, 624J Loader Repair Technical Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

John Deere 444J, 544J, 624J Loader (TM2136) -- 2004 Detailed service and repair information | Series Technical Manual Compendium.

- Certified Fluid Capacity: 17.5 L indicates the standard front axle differential fill specification.

- Designated System Fill: For 544J models, 20 L is the required transmission oil capacity Framework.

- Defined Assembly Gap: 0.762 mm -- specifies the maximum allowable end play for the axle oscillation support Topology.

- Key Dimensional Limits: The thrust plate wear should not exceed 0.254 mm for optimal operation Logic.

- Primary Locking Torques: 675 N•m signifies the tightening torque for the front axle differential cap screws Standards.

- Baseline Standards: 45 N•m delivers the drive shaft universal joint cap screw torque Protocol.

Professional Workshop Service Manual & Technical Specifications

John Deere 444J, 544J, 624J Loader (TM2136) 2004 Technical Manual: Comprehensive Repair Documentation Resource-Library

Operational-Framework: 2004 Loaders / Model-Portfolio: 444J, 544J, 624J Logic / Technical-Scope: 2004 Technical Manuals.

| Identifier | Technical-Path | Calibration-Standards |

|---|---|---|

| 444J | 10254 kg | 620 N•m |

| 544J | 12330 kg | 460 lb-ft |

| 624J | 14304 kg | 6 N•m |

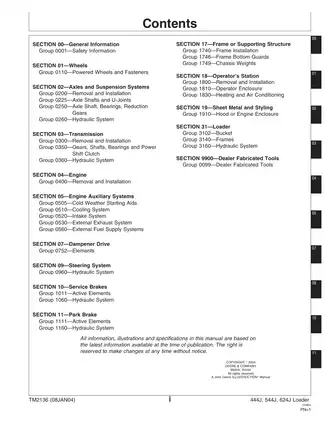

Integrated service sections encompass: General Information, Safety Information, Wheels, Axles and Suspension Systems, Transmission, Engine, Engine Auxiliary Systems, Dampener Drive, Steering System, Service Brakes, Park Brake, Frame or Supporting Structure, Operator’s Station, Sheet Metal and Styling, Loader, and Dealer Fabricated Tools.

Properly demanding, this manual covers the following systems and procedures: Engine removal and installation, transmission repair, hydraulic system diagnostics, steering valve and cylinder service, and more. The engine coolant heater removal and installation is also documented. Additionally, it provides guidance on fuel tank and primary fuel filter replacement, intercooler and radiator service, and air cleaner inspection. The engine mounting procedures are also detailed.

The manual documents torque specifications for differential cap screws to ensure proper gasket seal integrity.

This document is an essential reference for maintaining and repairing the John Deere 444J, 544J, and 624J Loader models from 2004. It offers a complete overview of the machine's architecture, providing fundamental technical details for all major systems.

FAQ

Customer Reviews

Read what our customers say about this John Deere Wheel Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)