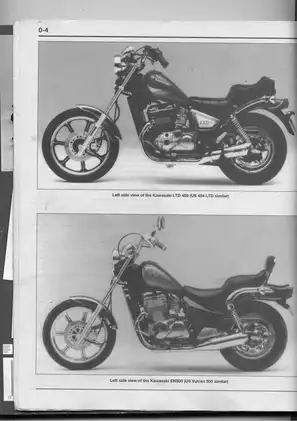

1985-2004 Kawasaki EN450 / EN500 Workshop Manual

EN450 and EN500 service documentation with fuel system, engine, and transmission specifications. Complete repair procedures and diagnostic tables for 454cc and 498cc parallel twin motorcycles including all maintenance intervals and torque values.

Manual Preview

Sample pages from the 1985-2004 Kawasaki EN450 / EN500 Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kawasaki EN450 & EN500 Twins — 1985–2004 Specialized Technical Resource | EN Twin Series Kit.

- Verified Ambient Limits: Engine oil viscosity ranges from SAE 10W40 or 10W50 (warm climates) to SAE 20W-40 or 20W-50 specifications, corresponding to optimal lubrication performance Architecture.

- Engineered Cycle Rate: For optimal performance, the engine idles at 1200 +/- 50 rpm (1985–1996) or 1300 +/- 50 rpm (1996 and later) defines the smooth idle operation Norms.

- Prescribed Size Parameters: Cylinder displacement achieves 454 cc (EN450) or 498 cc (EN500) — represents the engine volume capacity Bounds.

- Nominal Fastening Values: The cylinder head bolts require 51 Nm (38 ft-lbs) for 10 mm fasteners, calibrated to prevent gasket failure Topology.

- Defined Charge Quantity: Fuel tank capacity is rated at 11.0 liters (EN450/EN500 A) or 16.0 liters (EN500 C) for fuel storage Matrix.

- General Heat Tolerance: Coolant capacity reaches 1.4 liters (EN450/EN500 A) or 1.3 liters (EN500 C) and requires a 50/50 ethylene glycol-based antifreeze mixture Standards.

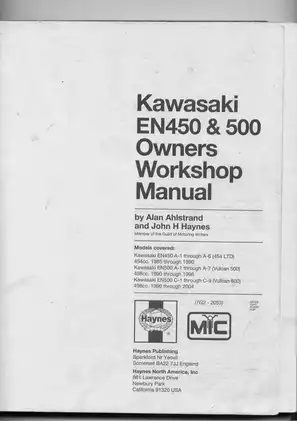

Professional Workshop Service Manual & Technical Specifications

Complete Factory Manual: Kawasaki EN450, EN500 (1985-2004) Operations-Manual

Model-Specs: EN450 A-1 through A-6, EN500 A-1 through A-7, EN500 C-1 through C-9 // Procedure-Type: Maintenance, Troubleshooting, Service Logic // Model-Specs: Parallel twin liquid-cooled architecture with DOHC valve train.

| Documentation Section | Coverage Scope | Reference |

|---|---|---|

| Engine Systems | Cylinder head, crankshaft, transmission, clutch, oil systems | Chapters 2, Technical specifications included |

| Maintenance Schedule | Routine intervals from 500 miles through 30,000 miles | Chapter 1, Complete schedule provided |

| Fuel & Exhaust | Carburetor types (Keihin CVK32, CVK34), intake manifold data | Chapter 4, Jet sizing documented |

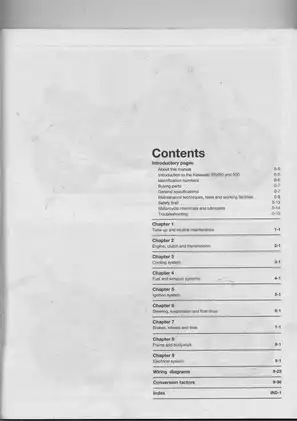

The manual organizes dedicated modules for tune-up and routine maintenance, which covers fluid level checks, brake and suspension inspection, and drive belt tension adjustment, while providing comprehensive ignition system information and engine disassembly guidance. Cooling system procedures include radiator inspection protocols, thermostat housing access, and water pump component removal, and transmission service spans shift drum positioning, fork alignment, and gear backlash verification. Electrical system documentation addresses battery electrolyte level checks, alternator rotor identification, and starter motor circuit configuration, and braking system chapters reference brake caliper assembly, disc pad specifications, and drum brake shoe replacement. Frame and bodywork sections document side cover fastening points and fuel tank mounting bracket details.

Operational Framework

Factory specifications are documented for compression ratios (EN450: 10.73:1, EN500: 10.8:1 standard), ignition system configuration (transistorized with IC igniter modules), and fuel system components (dual 34mm Keihin carburetors for EN450; 32mm for EN500 models). The document includes electrical connector identification, wiring harness routing diagrams, and battery terminal polarity marking. Suspension architecture specifications reference telescopic fork design and twin shock coil spring mounting points.

Modular Protocol

Engine rebuild procedures are documented for valve train removal (rocker arms, camshaft bearing caps with letter position markings), piston ring installation sequence (top compression, second compression, oil control ring components), and crankcase disassembly using RTV gasket sealant application. The manual provides cylinder head bolt tightening sequences with torque specifications (9.8 Nm for valve cover, 51 Nm for camshaft bearing caps), connecting rod side clearance measurement protocols using feeler gauges, and main bearing selection charts coordinated with crankshaft journal diameter marks.

Integrated Benchmarks

Drivetrain specifications are addressed in transmission gear ratio tables (primary reduction 2.952:1 for EN450, 2.652:1 for EN500; six-speed constant-mesh configuration), shift fork groove width tolerances, and clutch spring free length data. The document includes drive belt slack adjustment procedures (8.5 to 18.5 mm for EN450, 6.0 to 12.5 mm for EN500) and chain drive specifications for later models. Brake system documentation references hydraulic disc pad minimum thickness (4.0 mm), rear drum brake shoe inspection criteria, and brake fluid DOT ratings (DOT 3 through 1991, DOT 4 for later models).

Core Framework

Reassembly procedures are specified for piston installation with arrow orientation toward engine front, connecting rod bearing cap tightening order, and crankshaft endplay verification using feeler gauge insertion. The manual documents balancer shaft bearing oil clearance measurement using Plastigage strips, proper alignment of balancer gear marks with crankshaft gear positions to prevent engine vibration, and bearing insert selection based on crankcase bore diameter markings. Carburetor reassembly sections include float height adjustment (17 mm for EN450, -0.5 mm ±0 for EN500 models), jet needle positioning, and fuel level synchronization between dual carburetors.

Technical Sequences

Service intervals are documented for spark plug replacement at 6,000 mile intervals (NGK D9EA or equivalent), valve clearance adjustment at 500 miles and 6,000 mile intervals (intake 0.13-0.18 mm, exhaust 0.18-0.23 mm), and engine oil capacity with filter change (3.2 liters for standard fill). The manual includes tire pressure specifications differentiated by model year and geographic market, cooling system capacity data (1.4-1.3 liters depending on model year), and transmission gear oil requirements (SAE 10W-20 fork oil specification documented). Troubleshooting sections reference engine compression pressure ranges (EN450: 119-185 psi, EN500: 139-213 psi) and carburetor synchronization vacuum tolerance limits (less than 2 cm Hg difference between cylinders).

Factory specifications are documented for spark plug gap (0.6-0.7 mm), engine idle speed (1200-1300 rpm depending on model), and battery electrolyte specific gravity (1.280 at 68°F). The manual provides bolt torque values for oil drain plug (29 Nm), oil filter mounting (17 Nm), and cylinder head installation sequence specifications. Complete wiring diagram reference data is included for lighting circuits, starting motor relay configuration, and oil pressure switch connectivity, along with connector color coding and pin position identification for multiple model years spanning 1985 through 2004 production runs.

FAQ

Customer Reviews

Read what our customers say about this Kawasaki Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)