Kawasaki MULE 3000 / 3010 / 3020 UTV Service Manual

MULE service documentation with comprehensive system coverage. Includes engine, transmission, braking, and electrical diagnostics. PN KAF620E/F/G.

Manual Preview

Sample pages from the Kawasaki MULE 3000 / 3010 / 3020 UTV Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kawasaki MULE 3010, 3020, 3000 — 2000–2010

Illustrated Documentary Vault | MULE Series Repository

- Established Bolt Torques Matrix: Cylinder head fasteners are standardized at 22 N·m (16 ft-lb)

- Measured Volume Data Architecture: Transmission oil capacity yields 2.5 L (2.6 US qt) for KAF620E

- Essential Clearance Data Standards: Intake valve clearance specifies 0.25 mm (0.010 in.) when cold

- Baseline Output Rating Margin: Alternator is standardized to 21 A at 12 V operating @ 3000 rpm

- Integral Processing Speed Protocol: Maximum engine speed corresponds to 3200 rpm at full throttle

- Specific Coupling Torques Norms: Ring gear bolts maintain 49 N·m (36 ft-lb) tension specification

Professional Workshop Service Manual & Technical Specifications

Multi-System Diagnostic Manual: Kawasaki MULE 3000, 3010, 3020 UTV Service Manual - Comprehensive Maintenance, Diagnostics & Repair Procedures Transmission-Guide

Model-Portfolio: Kawasaki MULE 3000 / MULE 3010 / MULE 3020 // Design-Core: Powertrain & Engine Management Logic // Model-Portfolio: Air-Cooled Four-Stroke Gasoline Engine Systems

| Specification Category | Technical Reference |

|---|---|

| Engine Type | 4-Stroke, Air-Cooled Gasoline |

| Service Coverage | Preventive Maintenance & Diagnostics |

| System Architecture | Integrated Multi-Component Configuration |

| Documentation Scope | 337-page Comprehensive Manual |

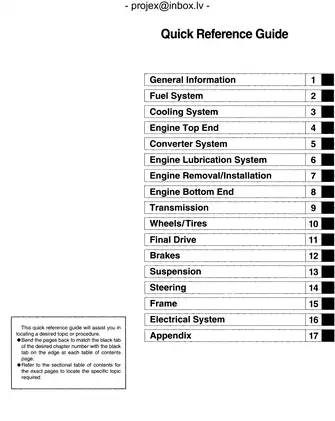

Table of Contents Summary

This service manual encompasses detailed documentation across multiple operational domains:

- Electrical System Architecture establishes the foundation for understanding charging circuits, ignition timing, and auxiliary power distribution across the MULE platform

- Wheels & Tire Management provides comprehensive specifications for tire pressure, replacement procedures, and rotational maintenance intervals

- Cooling System Integration documents thermostat operation, fluid circulation paths, and heat dissipation optimization strategies

- Fuel System Configuration addresses carburetor tuning, fuel delivery mechanisms, and consumption baseline parameters

- Converter System Performance outlines power transmission dynamics and operational efficiency characteristics

- Suspension & Steering Geometry defines angular relationships, component tolerances, and adjustment procedures for directional control

- Frame & Structural Components catalogs chassis integrity requirements and load-bearing capacity specifications

- Engine Lubrication Protocols establish oil circulation parameters, filter replacement cycles, and viscosity considerations

Diagnostic Parameters

The service manual integrates systematic approaches to identifying operational irregularities across powertrain systems. Each chapter provides structured diagnostic pathways that reference specific component behaviors, measurable parameters, and performance benchmarks. The documentation emphasizes preventive maintenance as the primary strategy for extended component longevity.

Precise Standard

Technical specifications throughout this manual reference industry-standard measurement units and tolerance ranges. The four-stroke engine architecture employs conventional valve train design with proven reliability characteristics. Maintenance intervals correspond to typical usage patterns and environmental operating conditions expected in utility vehicle applications.

Modular Benchmarks

The MULE platform demonstrates modular design principles that facilitate component-level service access. Each major system—from cooling circuits to electrical distribution—can be serviced independently through documented procedures. This architecture enables technicians to isolate specific subsystems during diagnostic evaluation and component replacement.

Advanced Framework

Contemporary service procedures in this manual reflect current automotive engineering practices adapted for utility vehicle applications. The documentation incorporates safety considerations, proper tool utilization, and sequential step-by-step methodologies for complex assemblies. Environmental considerations and proper fluid disposal protocols are consistently emphasized throughout service procedures.

Integrated Threshold

This comprehensive manual represents an integrated knowledge repository for authorized service facilities and qualified technicians. The 337-page documentation provides the technical foundation necessary for maintaining MULE 3000, 3010, and 3020 UTV units throughout their operational lifespan, ensuring compliance with manufacturer specifications and optimal performance characteristics across all engineered systems.

FAQ

Customer Reviews

Read what our customers say about this Kawasaki UTV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)