2003 Triumph Rocket III Motorcycle Service Manual

Complete engine management, transmission, fuel system, and maintenance procedures for 2294cc 3-cylinder DOHC motorcycle. Includes electrical, suspension, brake diagnostics.

Manual Preview

Sample pages from the 2003 Triumph Rocket III Motorcycle Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Triumph Rocket III (2003) Industrial Overview Toolkit.

- Calibrated Displacement Data: 2294 cc (140 cu in) is specified as the engine cylinder volume Architecture.

- System Power Output: For optimal performance, 142 PS at 5,750 rpm represents the maximum rated horsepower Specification.

- Published Torque Specification: 200 N·m (147 lb-ft) at 2,500 rpm governs the maximum crankshaft rotational force Framework.

- Authorized Compression Ratio: The combustion chamber requires 8.7:1 for standard ignition pressure Norms.

- Core Fuel Capacity: Tank volume establishes 25 litres (6.6 US gal) operational range Bounds.

- Standard Oil Capacity: Engine oil system sets 5.9 litres (1.56 US gal) for dry-sump configuration Protocol.

Professional Workshop Service Manual & Technical Specifications

Full-Coverage Assembly Assembly Manual: Motorcycle Triumph Rocket III Repair Manual - Precision Maintenance, Service & Troubleshooting Guide (2003) Diagnostic-Reference

Assembly-Group: Triumph Rocket III (2003) // Engineering-Base: Multi-system service / Powertrain operations Logic // Assembly-Group: Complete workshop documentation for longitudinal three-cylinder configuration.

| Service-Nexus | Diagnostic-Logic | Calibration-Standards |

|---|---|---|

| Cylinder Head Operations | Component Timing Data | Valve Clearance Reference Documentation |

| Crankshaft Assembly Procedures | Main Bearing Specifications | Journal Tolerance Parameters |

| Transmission Systems | Gear Selection Mechanics | Shift Fork Clearance Records |

| Lubrication Circuit Pathways | Pressure Relief Documentation | Oil Delivery Channel Specifications |

| Electrical System Integration | Sensor Position Reference | Control Module Connector Data |

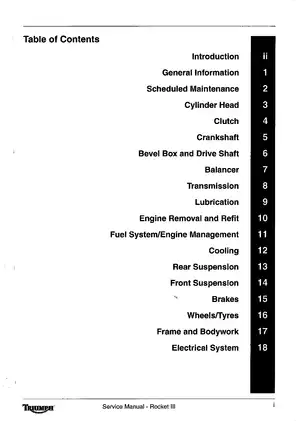

Documentation sections include Cylinder Head and Cam Drive Systems, Clutch Assembly and Actuation Mechanisms, Crankshaft and Connecting Rod Components, Transmission Gear Arrangement and Selector Operations, Lubrication System Distribution, Engine Removal Procedures, Fuel System and Injector Specifications, and Electrical Management Circuitry, concluding with comprehensive exhaust and evaporative system documentation.

Operational Parameters

Sequentially requiring complete understanding of the cylinder head architecture, this manual documents the three-cylinder DOHC engine layout with displacement of 2294 cc, producing maximum torque of 200 Nm at 2,500 rpm. The professional procedure sections address cam chain tensioning, camshaft identification and timing mark alignment, valve clearance measurement using feeler gauges, and shim selection methodology for inlet and exhaust valves ranging from 0.10 to 0.20 mm clearance specifications. Cylinder head bolt tightening employs three-stage progressive methodology, with specifications documented for both standard and service limit wear conditions.

Integrated Standard

Electrical system documentation covers engine management functionality including crankshaft position sensors, throttle position sensing, coolant temperature monitoring, and fuel injector circuit operation with diagnostic trouble code reference data. The manual provides complete sensor location diagrams, ECM connector pin numbering for both small and large connector assemblies, and detailed wiring circuit schematics for engine management system integration. Service technicians will discover on-board fault detection procedures, freeze-frame data retrieval methodology, and function test protocols utilizing the Triumph diagnostic tool.

Comprehensive Parameters

Suspension service documentation covers front fork specifications including 120 mm travel distance, oil level height documentation, spring rate calculation data, and damping cylinder bolt torque values. The manual documents torque specifications for suspension mounting bolts, yoke pinch fasteners, and handlebar clamp fixings, ensuring proper rotational loosening prevention for critical steering and suspension components. Rear suspension procedures address swinging arm pivot operations, suspension unit upper and lower mounting specifications, and final drive bevel box assembly alignment methodology.

Modular Benchmarks

Disassembly instructions are documented for piston ring gap measurement procedures, gudgeon pin circlip removal sequencing, and connecting rod small end bearing clearance assessment using Plastigage methodology. The manual addresses cylinder liner installation using the T3880061 extractor tool, piston skirt diameter verification at 101.561–101.577 mm standard dimensions, and ring groove clearance tolerance limits of 0.02–0.06 mm for top and second ring positions. Complete assembly procedures reference silicone sealer application to liner-to-crankcase mating surfaces and progressive engine rotation for piston ring seating verification.

Comprehensive Logic-Path

Wear limits are specified for all major engine components including camshaft journal clearance at 0.13 mm service limit, crankshaft main bearing journal tolerance of 43.068 mm minimum diameter, and connecting rod big end bearing clearance maximum of 0.100 mm before component replacement becomes mandatory. The manual documents torque specifications for the clutch centre nut at 105 Nm, transmission output gear fastening at 145 Nm, and final drive mounting bolts at 64 Nm maximum tightening specification to ensure proper rotational loosening prevention for all critical powertrain fasteners.

System operation descriptions cover the dry sump lubrication circuit with pressure pump delivery through the oil filter and main gallery distribution to crankshaft main bearings, transmission input and output shafts, and cylinder head cam bearing journals via internal drillings. Documentation includes scavenge pump operation collecting oil from front and rear sump locations, one-way valve function preventing tank oil drainage during engine shutdown, and piston cooling jet specifications for thermal management during extended operation. The manual documents torque specifications for the oil pump rotor tip clearance at 0.15 mm standard and pressure relief valve tightening at 15 Nm to ensure proper rotational loosening prevention during routine maintenance intervals.

FAQ

Customer Reviews

Read what our customers say about this Triumph Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)