2005 Suzuki GSX-R1000 / GSX-R1000 K5 Service Manual

Factory service manual for 2005 Suzuki GSX-R1000 and GSX-R1000 K5 motorcycles. Covers engine overhaul, fuel injection diagnostics, transmission repair, suspension adjustment, and complete brake system procedures with precise torque specifications (99500-39270-01E).

Manual Preview

Sample pages from the 2005 Suzuki GSX-R1000 / GSX-R1000 K5 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki GSX-R1000 / GSX-R1000 K5 — 2005 Engineering Consolidated Repository | GSX-R1000 Series Segment.

- Authorized Securement Values: The engine displacement specifies 999 cm³ (61.0 cu. in) is set to represent the four-cylinder liquid-cooled power unit Mapping.

- Published Fluid Capacity: For optimal lubrication, 3.3 L (3.5/2.9 US/Imp qt) corresponds to the engine oil requirement during filter change Configuration.

- Reference Gap Specs: The compression ratio reaches 12.5:1 as standardized to ensure proper combustion chamber pressure Benchmarks.

- Fundamental Power Draw: The idle speed is standardized to 1,150 ± 100 r/min specifies the baseline engine running parameter Range.

- Specific Print Rate: Fuel tank capacity limits 18.0 L (4.8/4.0 US/Imp gal) representing the standard fuel storage volume Sequences.

- Core Tension Specs: Engine coolant system capacity reaches 2.4 L (2.5/2.1 US/Imp qt) dictates the cooling system thermal management Baseline.

Professional Workshop Service Manual & Technical Specifications

Technical Field Manual: Motorcycle Suzuki GSX-R1000 / GSX-R1000 K5 Manual (2005) - Precision Maintenance, Troubleshooting & Factory Procedures Standards-Vault

Application-Range: GSX-R1000 (2005), GSX-R1000 K5 (2005) // Machine-Range: Liquid-cooled four-stroke motorcycle / Fuel-injection Logic // Component-Focus: Engine, transmission, chassis, electrical, and fuel delivery systems.

| System Coverage | Technical Focus | Documentation Scope |

|---|---|---|

| Engine and Fuel Management | Four-stroke DOHC architecture with FI diagnostics | Complete specifications provided |

| Transmission and Drive | Six-speed constant mesh with clutch assembly | See Chapter 3 |

| Chassis and Suspension | Inverted fork, link-type rear, dual disc brakes | Reference data included |

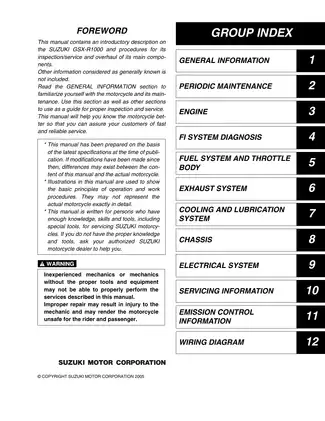

Strategically establishing coverage across general information and periodic maintenance, the manual documents engine specifications and component assembly, fuel system and throttle body operation, exhaust system control function, and cooling and lubrication system architecture, providing comprehensive reference material for service technicians and authorized mechanics.

Technical Interface

Verification procedures are included for engine compression pressure and oil pressure evaluation. The document contains detailed periodic maintenance schedules with service intervals measured in kilometers, miles, and time-based measurements. Specifications address air cleaner replacement at 18,000 km, spark plug service at 12,000 km intervals, and valve clearance inspection every 24,000 km. Engine oil change requirements and filter service schedules are documented with capacity specifications for standard, filter, and overhaul procedures.

Systematic Benchmarks

Repair information is provided for the electrical system diagnosis function, which includes self-diagnostic capabilities and malfunction code interpretation. The manual documents the FI system technical features incorporating injection time compensation signals from multiple sensors: intake air pressure, engine speed, throttle opening angle, atmospheric pressure, engine coolant temperature, and intake air temperature. Fail-safe function descriptions detail system operation when individual sensor signals are interrupted, allowing engine operation under degraded conditions. Wiring diagram references and ECM terminal assignments are included for circuit inspection and fault diagnosis.

Integrated Standard

The document includes coverage of drive chain maintenance with specific guidance on wear inspection, adjustment procedures, and cleaning requirements using kerosine. Brake system documentation encompasses pad wear limits, fluid specifications, air bleeding procedures, and master cylinder service information. Throttle valve synchronization procedures reference vacuum gauge operation and balance screw adjustment techniques. The manual provides torque specifications for fasteners across all major assemblies and documents torque specifications for the engine and transmission components to ensure proper assembly stress control.

Precise Architecture

Chassis components are documented with detailed construction drawings showing front wheel assembly, front fork internals, steering head configuration, rear shock absorber installation, and swingarm pivot points. Suspension setting procedures address preload and damping adjustments. Frame cover removal and fastener specifications are included. Cable routing diagrams and harness guidance information is documented for electrical and mechanical systems throughout the motorcycle.

Comprehensive Interface

Cooling and lubrication system pathways are documented with complete circuit diagrams showing oil galleries, main and sub-gallery pressure distribution, and component flow routes. The document includes engine coolant specifications with anti-freeze mixing ratios and boiling/freezing point curves. Air bleeding procedures for the cooling circuit and radiator cap pressure specifications are provided. Engine lubrication system charts display oil jet locations, bearing designations, and pressure regulator operation.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)