2001-2006 Dodge RAM 1500 Service Manual

Suspension, drivetrain, and brakes maintenance: camber/caster adjustment, pinion depth settings, differential carrier assembly. Complete factory specifications.

Manual Preview

Sample pages from the 2001-2006 Dodge RAM 1500 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Dodge RAM 1500 2001–2006 — 2001–2006 Precision Technical Portfolio | RAM 1500 Series Section.

-

Factory Current Rating: The 98 L (26 gal) short-box fuel tank is calibrated to support extended operational Benchmarks.

-

Essential Climate Specs: For optimal operation, the coolant system supports 15.4 L (16.2 qts) of antifreeze mixture defining the environmental Range.

-

Key Output Performance: Maximum engine power reaches 230 hp at 4,600 rpm representing the net crankshaft Sequences.

-

Verified Net Mass: The rear axle assembly is designed for 3.55–3.92 ratio gearing establishing differential Baseline.

-

Designated Assembly Torques: Ring gear bolts is specified as 108 N·m (80 ft. lbs.) for fastening Requirements.

-

Approved Wattage Specs: Automatic transmission fluid capacity defines 14–16 L (29–33 pts) dry-fill parameters Threshold.

Professional Workshop Service Manual & Technical Specifications

Definitive Operations Technical Manual: Truck Ultimate Maintenance & Repair: Dodge RAM 1500 (2001-2006) Procedure-Database

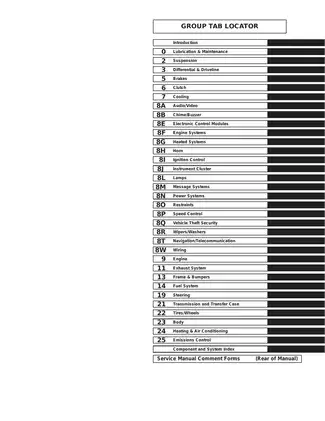

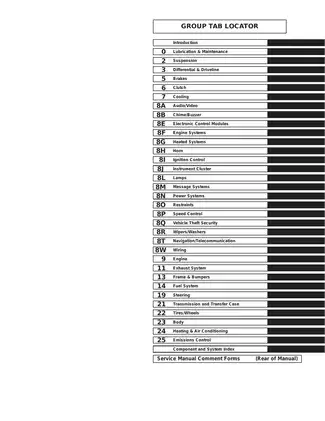

Procedure-Type: 2001–2006 Service Manual for Dodge RAM 1500 // Technical-Scope: Comprehensive System Coverage / Multi-System Integration // Procedure-Type: Factory Service Documentation, 4773 Pages.

| Assessment-Element | System-Path | Calibration-Data |

|---|---|---|

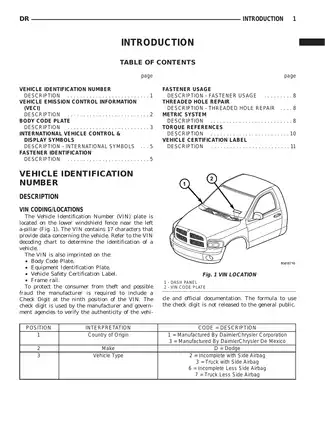

| Vehicle Identification & Certification | VIN Decoding, Body Code Plate, VECI Label | Complete reference specifications provided |

| Lubrication & Maintenance | Fluid types, capacities, maintenance schedules | Service interval documentation for gasoline and diesel variants |

| Suspension Systems | Wheel alignment, independent and link/coil suspensions | Torque specifications and adjustment procedures documented |

| Differential & Driveline | Propeller shafts, half shafts, front/rear axle assemblies | Multiple axle configurations with diagnostic and assembly procedures |

| Engine Systems | Cooling, exhaust, fuel, engine control modules | Component and system index provided |

| Braking & Restraints | Hydraulic systems, ABS, electronic controls | Complete specifications available |

The repository is divided into fundamental chapters addressing engine design, transmission operation, differential mechanics, suspension geometry, steering linkage, brake hydraulics, electrical subsystems, body structures, and emissions compliance. Documentation encompasses wheel alignment procedures, shock absorber diagnostics, spring configuration, stabilizer bar installation, and torsion bar adjustment. Drivetrain sections reference propeller shaft angles, universal joint assembly, half shaft removal, front axle C205F and 9 1/4 AA configurations, and rear axle variants including 9 1/4, 10 1/2 AA, and 11 1/2 AA assemblies. Lubrication and maintenance materials detail fluid types for gasoline and diesel engines, coolant specifications, transfer case requirements, and axle lubricant selection.

Core Protocol

Sequentially requiring systematic approach, the manual documents vehicle identification numbers with 17-character coding systems and references emission control information labels affixed to engine compartments. The document includes fastener identification standards distinguishing SAE and metric grades, threaded hole repair procedures using Helicoil methodology, and metric conversion formulas for precision circuit reference. Shock absorber bushings do not require lubrication; grease and mineral oil-base lubricants deteriorate the bushing rubber. The document specifies bearing preload adjustments ranging from 1.0 to 2.8 N·m depending on bearing condition and axle configuration. Service intervals follow Schedule A and Schedule B patterns, with maintenance procedures documented at 3,000-mile intervals during severe duty operation and 6,000-mile intervals under normal conditions.

Modular Interface

Drivetrain vibration diagnosis distinguishes between propeller shaft imbalance, universal joint wear, and driveline angularity concerns. The manual documents pinion bearing rotating torque specifications and differential case bearing preload requirements across multiple axle assemblies. Ring gear backlash measurements range from 0.076 to 0.203 mm (0.003 to 0.008 in.) depending on axle type. Front suspension sections cover independent control arm designs with torsion bar preload adjustment and coil spring compression tool specifications. The document provides hub/bearing installation procedures for both 4X2 and 4X4 configurations with distinct fastener torque requirements. Steering knuckle separation uses specialized pullers to prevent damage to ball joint seals and bearing surfaces.

Structured Architecture

The manual includes wiring diagrams for electrical subsystems, engine vacuum schematics from emissions control labels, and component location identification for removal and installation procedures. Differential assembly procedures reference clutch disc packs, Belleville spring washers, and side gear clearance measurement using feeler gauge methodology. Propeller shaft runout specifications limit deflection to 0.030 in. at shaft ends and 0.015 in. at center section. Pinion depth gauge sets establish correct ring and pinion tooth contact patterns using arbor discs and dial indicators positioned in bearing cradles. The document includes axle nut specifications requiring rotation cycles to seat wheel bearings followed by final torque application.

Systematic Benchmarks

Engine rebuild procedures are documented for gasoline variants (3.7L, 4.7L, 5.7L) and diesel engines (5.9L Cummins Turbo). Drivetrain specifications are addressed in separate chapters for manual transmissions (NV3500, NV4500, NV5600), automatic transmissions (45RFE, 48RE, 545RFE), and transfer case options (NV241 GENII, NV271, NV243, NV244 GENII, NV273). Reassembly procedures are specified for differential cases incorporating pinion shaft snap-ring installation, side gear thrust washer orientation, and bearing cap bolt sequencing to 61 N·m (45 ft. lbs.) or 165 N·m (122 ft. lbs.) depending on axle type. Service intervals are documented for engine oil changes, fluid level checks, brake lining inspection, spark plug replacement, and transmission fluid drain-and-fill cycles. Component locations are identified for upper and lower ball joints, stabilizer bar links, tie rod ends, shock absorber mounts, and suspension arm pivot points.

Advanced Framework

The document includes differential bearing adjuster lock procedures, pinion gear depth variance charts ranging from -4 to +4 marking values, and clutch pack preload compression specifications to 122 N·m (90 ft. lbs.) maximum. Trac-Lok limited slip differential operation references Belleville spring forces, clutch disc pack friction engagement, and rotating torque test procedures using specialized fixture equipment. Trac-Rite helical gear differential disassembly documents pinion brake shoe positioning, side gear thrust washer sequence, and inspection criteria for component chips or cracks. The manual documents torque specifications for bell housing bolts, exhaust manifold fasteners, cooling system hose clamps, and radiator mounting brackets. Wheel alignment procedures reference caster adjustment ranges of 3.55° to 4.7° depending on wheelbase and model designation, camber settings of -0.50° to +0.50°, and toe-in adjustments of 0.10° ± 0.05°.

The document documents torque specifications for the drivetrain to ensure proper rotational loosening prevention. These precise fastener values appear throughout suspension component installation, axle assembly procedures, and bearing preload adjustment sections, supporting the manual's function as a complete factory service reference for 2001-2006 Dodge RAM 1500 trucks across 1500, 2500, and 3500 series variants.

FAQ

Customer Reviews

Read what our customers say about this Dodge Truck manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)