1965-1986 Piper Cherokee Six PA-32-260/PA-32-300/PA-32R-300 Service Manual

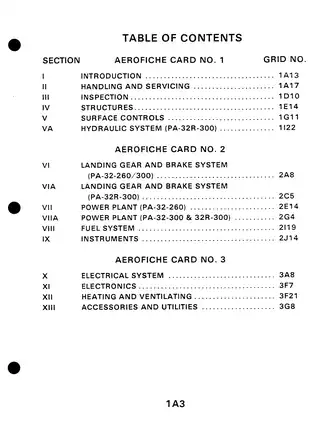

Complete service documentation for PA-32-260 (1965-1982), PA-32-300 (1965-1986), and PA-32R-300 (1976-1986) Cherokee Six aircraft. Covers airframe structures, landing gear systems, hydraulics, engine specifications, electrical systems, and complete rigging procedures.

Manual Preview

Sample pages from the 1965-1986 Piper Cherokee Six PA-32-260/PA-32-300/PA-32R-300 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Piper Cherokee Six PA-32-260, PA-32-300, PA-32R-300 — 1965–1986 Procedural Technical Vault | Cherokee Series Repository.

- Established Print Quality Data: Engine displacement reaches 10-540 cc (635 cu in) and is measured at the maximum rated cylinder volume Architecture.

- Operational Securement Values: Fuel tank capacity maintains 84 U.S. gallons total with 83.5 gallons usable on PA-32-260 and 300 models Protocol.

- Certified Liquid Volume: The fuel system produces an inboard (main) tank capacity of 25 U.S. gallons (each) representing baseline storage capacity Norms.

- Factory Power Rating: Engine horsepower delivers 260 hp at 2700 rpm for PA-32-260, and 300 hp at 2700 rpm for PA-32-300 and PA-32R-300 specifications Bounds.

- Approved Working Temperature: Oil sump capacity maintains 12 U.S. quarts for all engine models and limits thermal operational parameters Topology.

- Measured Output Quality: Main landing gear oleo strut extension reaches 4.50 inches ± .25 inches on PA-32-260 and 4.50 inches ± .50 inches on PA-32-300, establishing shock absorption standards Architecture.

Professional Workshop Service Manual & Technical Specifications

Professional Training Workshop Manual: Aircraft Genuine Piper Cherokee Six PA-32-260, PA-32-300, PA-32R-300 Service Manual Repair-Index

Technical-Domain: Piper PA-32-260 (1965-1982), PA-32-300 (1965-1986), PA-32R-300 (1976-1986) // System-Coverage: Airframe, propulsion, hydraulic, and brake system documentation / Landing gear assembly networks // Technical-Domain: 735-page comprehensive service reference with aerofiche grid coordination system.

| Identifier | Operational-Logic | Framework |

|---|---|---|

| Structural Systems | Wing assembly, empennage, fuselage configuration | Section IV with attachment specifications |

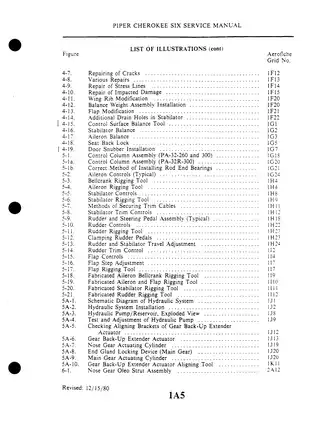

| Surface Control Networks | Aileron, stabilator, rudder, flap mechanisms | Section V with rigging procedures |

| Powerplant Documentation | Engine installation, magneto timing, propeller governance | Sections VII-VIIA covering Lycoming platforms |

The documentation is partitioned into inspection intervals, handling procedures, and maintenance sequences addressing engine systems, landing gear retraction mechanisms, fuel system distribution networks, and electrical system logic components. Covers inspection protocols, fuel selector positioning sequences, brake cylinder documentation, hydraulic pump reservoir networks, and oleo strut servicing procedures providing comprehensive overview of aircraft operational systems.

Modular Logic-Path

Adjustment procedures are detailed for control surface travel specifications, cable tension calibration, and trim mechanism positioning. The manual provides strategic reference data for bellcrank rigging calculations, aileron balance weight modification, and flap attachment security. Technical notes are provided for magneto timing marks, carburetor adjustment parameters, and propeller governor control sequences including impulse coupling verification.

Structured Framework

Fuel system procedures are documented for tank interconnection logic, fuel selector valve positioning, and quick drain outlet identification across main tank and tip tank networks. The document references torque specifications for landing gear attachment bolts, engine mount fastening sequences, and control surface hinge security ensuring proper assembly integrity.

Integrated Interface

Quality checks are addressed for wheel bearing repackaging intervals, strut extension measurement validation, and tire pressure verification at 50-hour, 100-hour, 500-hour, and 1000-hour inspection checkpoints. Documentation includes lubrication point mapping, grease fitting application protocols, and control cable tension measurement procedures using tensiometer reference standards.

Diagnostic Parameters

Includes wiring schematic diagrams, electrical system component load calculations, and instrument calibration reference data. The manual documents troubleshooting decision trees for landing gear extension malfunctions, fuel pump operation verification, and magneto performance validation. Provides component identification methodology with aerofiche card grid location referencing system enabling rapid technical content retrieval.

The manual documents torque specifications for structural components to ensure proper cyclic stress resistance across all major assemblies including wing spar attachment points, stabilator hinge mechanisms, and landing gear installation interfaces.

FAQ

Customer Reviews

Read what our customers say about this Piper Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)