1960-1981 Piper PA-23-235 Apache & PA-23-250 Aztec Service Manual

Comprehensive service documentation covering landing gear, hydraulic systems, fuel systems, engines, and electrical components. PN 753564

Manual Preview

Sample pages from the 1960-1981 Piper PA-23-235 Apache & PA-23-250 Aztec Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Piper PA-23-250 Apache & PA-23-250 Aztec — 1960–1981 Structured Manual Archive | Aztec Series Repository.

- Calibrated Displacement Data: 10-540-C4B5, 10-540-J4A5 and TIO-540-C1A engines are configured at 250 horsepower rated output Benchmarks.

- Prescribed Fuel System Capacity: For complete aircraft operation, 144 U.S. gallons (five-gallon reserve) is established at the total fuel tank configuration Range.

- System Oil Sump Volume: The engine oil sump requires 12 U.S. quarts of SAE-specified grade lubricant maintaining optimal thermal performance Sequences.

- Calibrated Tire Pressure Data: Main landing gear tires are configured at 42–46 psi, nose gear at 27–32 psi depending on gross weight Baseline.

- Documented Control Surface Travel: Aileron deflection is established at 30° ± 2° from neutral, rudder at 25° ± 1° for maximum control authority Requirements.

- Defined Stabilator Anti-Servo Range: Stabilator movement indicates 9°–10° down and 3°30' up from level, trim tab position maintains independent actuation Threshold.

Professional Workshop Service Manual & Technical Specifications

Unified Workshop Service Manual: Piper PA-23-235 Apache & PA-23-250 Aztec Aircraft Service Documentation Set

Performance-Values: PA-23-235 Apache (1960–1981), PA-23-250 Aztec (1960–1981), PA-23-250 (six place) Aztec variants (1972–1981) // System-Identifier: Twin-engine aircraft maintenance and systems integration // Operational-Scope: Comprehensive technical reference for professional aircraft technicians covering 1,335 pages of service procedures and component documentation.

| Documentation Category | Content Focus | Framework |

|---|---|---|

| Ground Operations | Handling, jacking, weighing, leveling, towing | Section II—foundational procedural reference |

| System Maintenance | Hydraulic, brake, fuel, electrical systems | Sections VI, VII, VIII, IX documentation |

| Structural Components | Wing, fuselage, empennage assembly and repair | Section IV comprehensive assembly data |

| Flight Control Systems | Aileron, stabilator, rudder actuation and rigging | Section V control surface specifications |

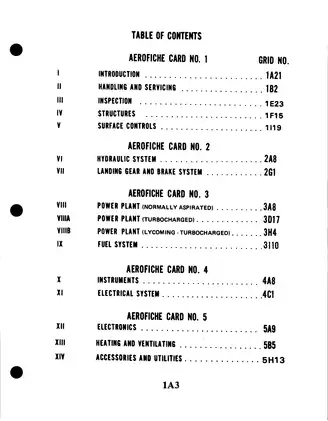

The repository is divided into fourteen major sections, establishing comprehensive coverage of engine and propulsion systems, integrating hydraulic and fuel delivery mechanisms, connecting landing gear and brake assemblies, and addressing instrumentation and accessory installations across the aircraft platform.

Advanced Nexus

Drivetrain specifications are addressed in the propeller and engine installation chapters, documenting constant-speed propeller models (Hartzell full feathering units), engine variants (Avco-Lycoming six-cylinder horizontally opposed), and governor control systems for both normally aspirated and turbocharged powerplants. The manual provides references to component part numbers, installation mounting sequences, and compatibility matrices for serial number ranges spanning three decades of production.

Strategic Topology

Reassembly procedures are specified for the structural assemblies including wing attachment to fuselage through main spar and front spar mounting brackets, stabilator torque tube connection mechanisms, and landing gear oleo strut assembly with actuating cylinders. Documentation includes dimensional specifications for bushing and washer applications, bolt torque values for structural integrity, and alignment verification procedures using fabricated tools and reference marking systems.

Technical Logic-Path

Service intervals are documented for routine maintenance operations including oil system servicing (50-hour change intervals), hydraulic system replenishment (100-hour checks), tire pressure and brake fluid level verification, and fuel system strainer cleaning (50-hour or 90-day intervals, whichever occurs first). The inspection report establishes systematic procedures across propeller examination, engine component verification, cabin and fuselage integrity checks, wing and control surface assessment, and landing gear functional testing with defined circles marking required inspection points.

Strategic Logic-Path

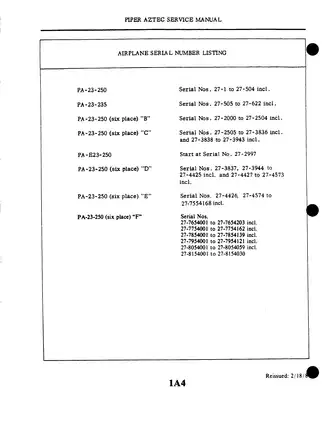

Component locations are identified for all major systems through access plate diagrams showing inboard and outboard inspection openings, fuel filler caps, oil service points, hydraulic reservoir filler tubes, and brake system components distributed across both fuselage sections and engine nacelles. The document maps service point accessibility for PA-23-250, PA-23-235, and six-place Aztec variants with serial number ranges, enabling technicians to efficiently locate lubrication fittings, fluid screens, filter elements, and actuator assemblies.

Engineered Logic-Path

Service procedures are documented for control surface rigging including aileron cable tension specifications (40 lbs ±25%-0%), stabilator anti-servo travel limits (9°-10° range with level reference), rudder pedal neutral positioning (12° aft of vertical), and trim tab free play tolerances (maximum 1/10 inch). The manual includes rigging and adjustment methodologies for both primary and secondary control systems, detailing turnbuckle station settings, cable routing configurations, and pulley mounting bracket specifications to achieve factory-standard control response characteristics.

The technical units are distributed across environmental conditions, operational scenarios, and aircraft configurations, providing altitude performance data for oxygen system pressurization, propeller chamber pressure requirements versus ambient temperature, and heating/ventilating system capacity specifications. Documentation encompasses materials specifications (consumable supplies including hydraulic fluids per MIL-H-5606, lubricating oils per grade and seasonal temperature requirements, and protective sealants), torque specifications for flare fitting assemblies and structural hardware, and conversion tables for metric and imperial measurement equivalents.

This comprehensive manual documents torque specifications for the structural fasteners and fluid system connections to ensure proper assembly and maintain system reliability across the aircraft service life.

FAQ

Customer Reviews

Read what our customers say about this Piper Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)