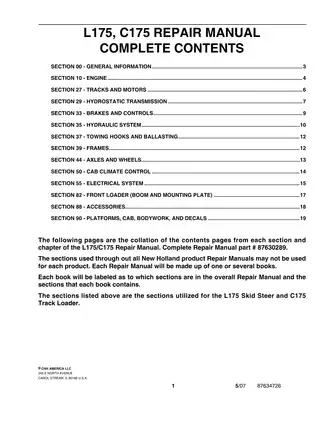

2007 New Holland L175 Skid Steer / C175 Track Loader Repair Manual

Professional service procedures for 2007 L175 wheeled and C175 track loaders with N844LT turbo engines. Comprehensive repair coverage for hydrostatic transmission, hydraulic systems, engine, tracks and all major components.

Manual Preview

Sample pages from the 2007 New Holland L175 Skid Steer / C175 Track Loader Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland L175 & C175 (N844LT) — 2007 Automotive Reference Manual | Skid Steer & Track Loader Toolkit.

- Established Print Rate Specifications: Engine displacement reaches 2212 cu. cm (135.0 cu in) is designed for the N844LT diesel architecture Bounds.

- Reference Dimensional Limits: For optimal loader performance, bore measures 84 mm (3.30 in) controls the cylinder bore topology Matrix.

- Certified DPI Rating Data: Compression ratio is measured at 22 to 1 delivers maximum combustion chamber Standards.

- Factory Volume Data: Fuel tank capacity reaches 54.5 L (14.4 gal) indicates the fuel storage margin Margin.

- Integral Running Clearance: Maximum engine speed is specified as 3050 ± 25 RPM (NA Machines) indicates peak operational protocol Protocol.

- Specific RPM Specs: Peak torque delivery reaches 173 N·m (128 ft. lbs.) at 1700 RPM is specified as the crankshaft power rating Guidelines.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Shop Technical Manual: 2007 New Holland L175 Skid Steer & C175 Track Loader - Professional Service System-Standards

Asset-ID: L175 Skid Steer Loader, C175 Track Loader, L175 Wheeled Machine, C175 Compact Track Loader // Technical-Scope: Engine, Transmission, Hydraulic System, and Powertrain Service Logic // Equipment-Series: Complete 1007-page factory service documentation with detailed component assembly specifications and maintenance schedules.

| Performance-Element | Rating | Calibration-Spec |

|---|---|---|

| Engine Systems | N844LT Diesel Turbo | Comprehensive overhaul procedures documented |

| Transmission Components | Hydrostatic Variable Displacement | Pump and motor service sequences included |

| Hydraulic Operations | Boom and Bucket Circuits | System pressure and flow testing documented |

| Track Systems | Rubber Track Assembly | Tension adjustment and roller service covered |

| Electrical Architecture | 12V Battery and Alternator | Wiring diagrams and circuit troubleshooting included |

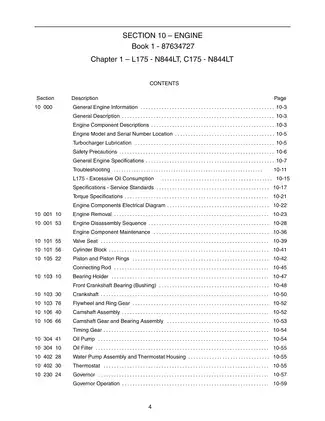

Thoroughly demanding maintenance information encompasses the engine and transmission systems, the hydrostatic transmission assembly, and hydraulic boom and bucket control operations. The documentation provides detailed coverage of engine component descriptions, including cylinder block specifications, crankshaft design, piston and connecting rod assemblies, and camshaft configurations. Suspension service documentation covers the final drive systems, track tension adjustment procedures, and idler wheel specifications for both wheeled and track variants.

Strategic Nexus

Disassembly instructions are documented for the N844LT turbocharged diesel engine, encompassing the complete removal sequence from fuel injection pump through cooling system components. The manual includes engine reassembly specifications with detailed torque values for all fasteners and assembly procedures to ensure proper component alignment. Comprehensive coverage addresses both the L175 skid steer and C175 track loader configurations with model-specific variations noted throughout.

Diagnostic Sequences

System operation descriptions cover the hydrostatic transmission neutralizer assembly, charge pressure testing, pump and motor efficiency evaluations, and control lever adjustment procedures. The documentation includes detailed specifications for both mechanical control and pilot control transmission systems, with step-by-step removal and installation sequences for hydrostatic pump and motor units. Testing procedures are documented for charge system pressure, case drain function, high-pressure operation, and air ingress detection in both hydraulic and hydrostatic circuits.

Technical Methodology

Wear limits are specified for engine components including valve seats, cylinder bore dimensions, piston clearances, and crankshaft journal specifications with allowable service limits provided for each measurement point. Track drive motor disassembly and reassembly procedures document the brake disc package assembly, gear box servicing, spool valve configurations, and final drive housing oil capacity and grade specifications. The manual includes comprehensive specifications tables for bolt torque values, hardware identification, and component measurement standards.

Operational Protocol

The document includes special tools references for engine service operations, compression testing adapters, oil pressure testing fittings, and hydraulic system measurement equipment needed for factory-level maintenance procedures. Cooling system specifications document the radiator capacity, thermostat operating temperature ranges, and antifreeze mixture requirements for seasonal operation. Fuel system components are illustrated with detailed descriptions of the fuel tank pickup tube configuration, electric fuel pump operation, injection pump timing procedures, and fuel filter service intervals measured in operating hours.

Precise Topology

Labor guide estimates are provided for major engine overhaul operations, cylinder head service, piston and connecting rod replacement, and complete hydrostatic transmission rebuilds with turbocharged engine variations noted where applicable. The manual documents torque specifications for the cylinder head installation in three-step tightening procedures, crankshaft pulley retention, connecting rod fasteners, and fuel injection nozzle assembly. Complete wiring diagrams are included for the electrical system, including starting circuits, power distribution, instrument cluster monitoring, glow plug heating systems, and optional equipment integration for loader arm auxiliary controls and two-speed transmission variations.

The document provides detailed specifications for the L175 and C175 models including engine horsepower ratings, travel speeds, tire inflation pressures, and operating load capacity ratings per SAE standards. Dimension drawings are documented showing overall machine height, bucket dump reach at maximum height, turning radius measurements, ground clearance specifications for chain case and belly pan, and wheelbase measurements. Cooling system operation descriptions include the thermostat function at specific temperature thresholds and the EIC electronic instrument cluster monitoring and overheat warning procedures. The manual documents torque specifications for the boom and bucket cylinder pivot pins, attachment mounting plate fasteners, and ROPS frame installation sequences for both standard and cab upgrade machine configurations.

FAQ

Customer Reviews

Read what our customers say about this New Holland Skid Steer Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)

OK IN FRENCH.