2005-2008 Porsche Cayman / Boxster Service Repair Manual

Covers Cayman S, Boxster, Boxster S models with comprehensive service procedures for ABS/PSM, air conditioning, automatic transmission, and airbag systems. Factory diagnostic procedures using PIWIS Tester P 9718.

Manual Preview

Sample pages from the 2005-2008 Porsche Cayman / Boxster Service Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Porsche Cayman S, Boxster S — 2005–2008 Diagnostic Manufacturer Overview | Cayman S Series Segment.

- Authorized Load Capacity: Refrigerant quantity of 900 g R134a is standardized to the air-conditioning system Requirements.

- Critical Environmental Range: For optimal operation, high-pressure cut-off at 32 bar defines the maximum system pressure Framework.

- Operational RPM Specs: Low-pressure cut-off threshold reaches 1.4 bar at ambient temperatures above 5°C Threshold.

- Established Installation Footprint: The pressure relief valve purge pressure achieves 40 bar system protection Mapping.

- Measured Threaded Fastener Data: Servo motor fastening screws are specified to 1.2 Nm (1.0 ftlb.) with tolerance ±0.5 Nm Configuration.

- Maximum Voltage Specs: Refrigerant oil filling capacity reaches 195 ±15 cm³ ND 8 for complete circuit Benchmarks.

Professional Workshop Service Manual & Technical Specifications

Certified Overhaul Manual: Porsche Cayman S - Comprehensive Service & Diagnostics Manual (2005-2008) System-Standards

Component-Focus: Boxster (2005-2007), Cayman S (2006-2007), RHD models // Equipment-Series: Brake system, HVAC, transmission control / Electrical integration Logic // System-Identifier: 5,679 pages, 85.11 MB archive.

| Component | Baseline | Calibration-Data |

|---|---|---|

| Brake hydraulics | PSM/ABS module architecture | PIWIS Tester diagnostic protocols documented |

| Climate control | Climatronic refrigerant circuit | R134a charge specifications referenced |

| Automatic transmission | Multi-functional selector interface | ATF capacity and ratio data included |

| Occupant protection | Airbag triggering unit configuration | AWS weight sensing calibration procedures |

| Drive system | Torque converter mechanics | Adapter pin positioning documented |

Systematizing the service groups into brake assemblies, climate systems, transmission actuation, and electrical safety protocols, the documentation encompasses engine compartment operations, desiccant replacement procedures, servo motor functionality, and pressure switch verification. The manual orchestrates suspension and steering alignment specifications, foundation bolt torque documentation, and wiring harness integrity checks across all model variants including RHD configurations.

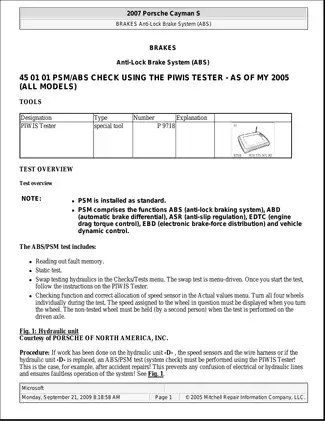

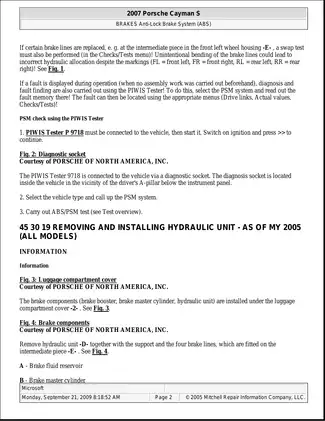

Integrated Protocol

Reference data is included for anti-lock braking system diagnostics using PIWIS Tester instruments, encompassing static functionality assessment, hydraulic line verification, and electronic control unit interrogation. The document provides comprehensive schematic layouts for ABS pump operation, solenoid valve assignment protocols, and sensor responsiveness measurement. Alignment specifications are included for steering-angle sensor calibration procedures, requiring vehicle placement on measuring platforms with precise wheel geometry confirmation.

Operational Threshold

This manual covers air-conditioning system maintenance encompassing refrigerant extraction protocols, expansion valve positioning, evaporator access procedures, and compressor mounting verification. Diagnostic procedures are covered for climate control regulator coding using system tester interfaces, dryer replacement timing, magnetic coupling air gap measurement, and servo motor functional testing. The document includes torque specifications for refrigerant line connections to ensure proper circuit integrity.

Precise Logic-Path

Wiring diagrams are provided for transmission multi-function switch operation, selector lever cable routing, tiptronic control module programming sequences, and automatic transmission assembly procedures. The manual documents selector shaft sealing ring installation, transmission support mounting orientation, drive shaft coupling methodology, and torque converter bolt fastening patterns. Complete ATF filling capacity reference data appears throughout, alongside transmission control unit replacement programming instructions requiring PIWIS Tester connection protocols.

Core Framework

Occupant safety system documentation addresses airbag contact unit centering procedures, driver and passenger module removal sequences, side airbag mounting verification, head airbag connector protocols, and belt tensioner triggering assessment. AWS control unit calibration procedures are detailed with test weight application and passenger seat positioning requirements. The manual includes roll-over bar adjustment measurement dimensions, three-point seat belt installation methodology, and triggering unit programming sequences using specialized diagnostic equipment.

Core Nexus

Correct procedures for electrical connector locking mechanisms, battery disconnection protocols following airbag service work, and diagnostic fault code interpretation using PIWIS Tester instrumentation are documented throughout. The resource addresses vehicle handover procedures, adaptation value resetting for transmission control modules, and security code retrieval for steering angle sensor calibration. Safety protocols for refrigerant handling, pyrotechnical component storage, and hazardous material disposal requirements appear in dedicated procedural sections.

FAQ

Customer Reviews

Read what our customers say about this Porsche Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)