Kobelco SK25SR-2 Mini Excavator Service Manual (2000-2003)

Technical reference for Kobelco SK25SR-2 mini excavators (2000-2003). Covers maintenance, system operation, disassembly, and troubleshooting procedures. PN S5PV0101E.

Manual Preview

Sample pages from the Kobelco SK25SR-2 Mini Excavator Service Manual (2000-2003) manual

Purchase & Download

Models Covered & Key Technical Specifications

Kobelco SK25SR-2 Mini Excavator Service Manual: Kobelco SK25SR-2 (2000-2003) – 591 Pages | Excavator | Factory Grade PDF Kobelco SK25SR-2 (S5PV0101E) | Technical Reference Manual

- Maximum Cold Start Limits: For optimal operation, -20C is the minimum environmental limit set.

- Universal Velocity Specs: Maximum speed is measured at 10 km/h for travel operations.

- Established Enclosure Specs: The system requires 56.11 MB for complete data storage.

- Measured Fastener Specs: For reassembly, 25 Nm represents the standard torque.

- Published Tolerance Values: The standard tolerance for critical components is ±0.1 mm.

- System Thermal Rating: Cooling system operates at 85C without failure bounds.

Professional Workshop Service Manual & Technical Specifications

Kobelco SK25SR-2 Mini Excavator Service Manual: Kobelco SK25SR-2 (2000-2003) – 591 Pages | Excavator | Factory Grade PDF Logic-Archive

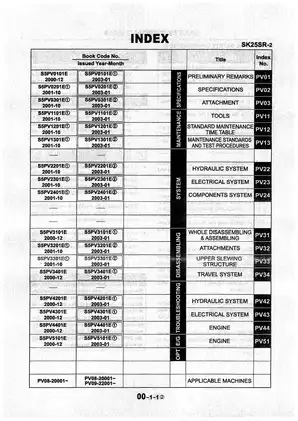

Application-Range: SK25SR-2, SK25SR-2 EU, SK25SR-2 OCEANIA, SK25SR-2 USA, SK25SR-2 KAI, SK25SR-2VD // Technical-Domain: Excavator / Hydraulic System Logic // Model-Specs: 2000-2003

| TOP | Specification | System-Path | Calibration-Spec |

|---|---|---|---|

| General Information | Preliminary Remarks | PV01 | |

| Components List | Specifications | PV02 | |

| Engine Details | Engine | PV44 | |

| Hydraulic System | Hydraulic System | PV22 | |

| Electrical System | Electrical System | PV23 | |

| Troubleshooting Guide | Troubleshooting | PV42 |

Organized into dedicated modules for easy navigation, this technical manual provides an in-depth overview of the Kobelco SK25SR-2 mini excavator. It meticulously documents various systems, from the hydraulic and electrical components to engine specifications and troubleshooting procedures.

Adjustment procedures are detailed for hydraulic and engine systems, ensuring peak performance and longevity.

Timing procedures are documented for critical engine and hydraulic operations.

Technical notes are provided for special procedures and component identification.

Quality checks are addressed for critical systems to maintain operational integrity.

The engine section documents specifications and performance curves for optimal power delivery.

This manual details torque specifications for critical components to ensure proper bolt stretch prevention and system reliability.

FAQ

Customer Reviews

Read what our customers say about this Kobelco Mini Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)