1993 Mitsubishi Montero Service Manual

Comprehensive 1993 Mitsubishi Montero service guide. Covers engine mechanical adjustments, valve clearance, ignition timing, and troubleshooting for driveability issues. Part 316122-001.

Manual Preview

Sample pages from the 1993 Mitsubishi Montero Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

1993 Mitsubishi Montero Service Manual: Mitsubishi Montero Powertrain-Manual

Service Manual: Mitsubishi Montero | Engine Mechanical Manual

System Diagnostics: 1993 Montero systems analysis provides comprehensive diagnostic insights. Engine Mechanical: 1993 Montero engine mechanical procedures are clearly outlined. Valve Clearance: 1993 Montero valve clearance specifications are detailed. Ignition Timing: 1993 Montero ignition timing procedures are specified. Driveability: 1993 Montero driveability adjustments are covered. Basic Testing: 1993 Montero basic testing protocols are documented.

Professional Workshop Service Manual & Technical Specifications

1993 Mitsubishi Montero Service Manual: Mitsubishi Montero Powertrain-Manual

Engineering-Metrics: 1993 Montero Service Manual // Conceptual-Layout: Engine Mechanical / Ignition System Logic // Engineering-Metrics: On-Vehicle Adjustments.

Engine Mechanical

Before performing any on-vehicle adjustments to fuel or ignition system, ensure engine mechanical condition is okay.

Valve Clearance

NOTE: These models use hydraulic lash adjusters and do not require periodic valve adjustment.

Valve Adjustment

CAUTION: DO NOT rotate crankshaft in opposite direction of normal engine rotation.

Checking Hydraulic Valve Lifters

- Warm engine to normal operating temperature. Remove valve cover. Position cylinder No. 1 at TDC on compression stroke. Check intake rockers on cylinders No. 1 and 2. Check exhaust rockers on cylinders No. 1 and 3.

- Push downward on end of rocker arm above lash adjuster. Rotate crankshaft 360 degrees and check intake rockers on cylinders No. 3 and 4. Check exhaust rockers on cylinders No. 2 and 4. If lash adjuster is normal, it will feel solid.

- If lash adjuster moves downward easily when pushed, replace adjuster. If lash adjuster feels soft or spongy, air has probably entered lash adjuster. If this occurs, check engine oil level. If engine oil level is okay, check oil screen and oil screen gasket for damage.

- After repairing cause of air leak, warm engine to operating temperature. Drive vehicle at low speed for approximately 5 minutes. Turn engine off for a few minutes.

- Restart engine and drive at low speed for approximately 5 minutes. Repeat this step several times for about one hour. This helps remove air from engine oil.

Ignition Timing

NOTE: Perform all adjustments with engine at normal operating temperature, cooling fan and accessories off, transmission in Park or Neutral, and front wheels in straight-ahead position.

NOTE: Adjustment of ignition timing cannot be performed on vehicles equipped with Distributorless Ignition Systems (DIS). If ignition timing is not within specification, see CRANKSHAFT POSITION SENSOR in I - SYS/COMP TESTS article in this section.

- Locate ignition timing adjustment connector. See IGNITION TIMING ADJUSTMENT CONNECTOR LOCATION table. Connect jumper wire between ignition timing adjustment connector and ground. Check ignition basic timing.

- If ignition basic timing is not within specification, loosen distributor and rotate to adjust timing if necessary. See IGNITION TIMING SPECIFICATIONS table. Remove jumper wire from ignition timing adjustment connector.

Idle Speed & Mixture

NOTE: Perform adjustments with engine at normal operating temperature, cooling fan and accessories off, transmission in Park or Neutral, and front wheels in straight-ahead position.

Curb (Slow) Idle Speed

NOTE: Curb idle speed is controlled by Idle Air Control (IAC) motor. Adjustment is usually not necessary. For curb idle speed specifications, see IDLE SPEED SPECIFICATIONS table under BASIC IDLE SPEED.

- Check ignition timing and adjust if necessary. See IGNITION TIMING. Run engine at 2000-3000 RPM for more than 5 seconds. Allow engine to idle for 2 minutes. Check curb idle speed.

- If curb idle speed is not within specification, check IAC system. See I - SYS/COMP TESTS article in this section. If IAC system is okay, adjust basic idle speed. See BASIC IDLE SPEED.

Basic Idle Speed

NOTE: ALWAYS check TPS adjustment after adjusting basic idle speed. See THROTTLE POSITION SENSOR (TPS).

NOTE: For Data Link Connector (DLC) location, see G - TESTS W/CODES article in this section.

NOTE: Ensure vehicle is at normal operating temperature with all lights, cooling fan and accessories off. Shift transmission into Neutral or Park position.

- Insert paper clip or appropriate probe into tachometer connector. See TACHOMETER CONNECTOR LOCATION table. Connect a primary voltage detecting type tachometer to paper clip.

- Connect a jumper wire between data link terminal No. 10 and vehicle ground. See Fig. 1. Connect a jumper wire between ignition timing adjustment connector and vehicle ground. See IGNITION TIMING ADJUSTMENT CONNECTOR LOCATION table under IGNITION TIMING.

- Start and run engine at idle. Check basic idle speed. See IDLE SPEED SPECIFICATIONS table. If idle speed is not within specifications, turn engine speed adjusting screw until correct engine speed is obtained. See Fig. 2. Access to speed adjusting screw is obtained by removing rubber plug on throttle body.

- If idle speed cannot be lowered by adjusting engine speed adjusting screw, determine if fixed speed adjusting screw (stop screw contacting throttle lever) has been adjusted. See FIXED SPEED ADJUSTING SCREW for procedure.

- After all adjustments are verified correct, possible cause of incorrect idle speed is deterioration of fast idle air control motor. Throttle valve must be replaced to correct symptom. Disconnect jumper wires and recheck idle speed.

Idle Mixture

NOTE: Idle mixture is computer controlled on fuel injected engines and is nonadjustable. CO level specifications are not available from manufacturer.

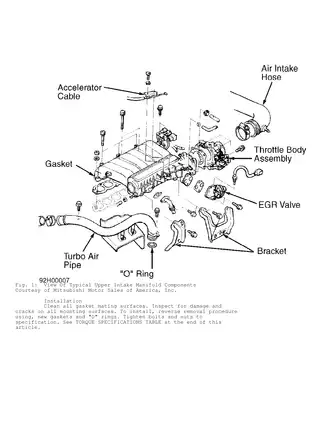

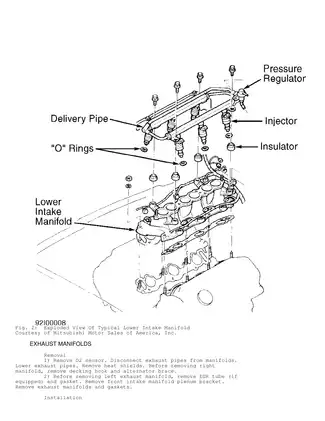

Torque Statement: The manual documents torque specifications for various engine components to ensure proper assembly consistency.

FAQ

Customer Reviews

Read what our customers say about this Mitsubishi SUV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)