Mitsubishi MT160 / MT180 / MT210 / MT250 Tractor Service Manual (75 P.)

MT160 through MT250 technical guide detailing engine, transmission, hydraulic systems, brakes and differential assemblies. Complete repair procedures for all major tractor components.

Manual Preview

Sample pages from the Mitsubishi MT160 / MT180 / MT210 / MT250 Tractor Service Manual (75 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Mitsubishi MT160, MT160D, MT180, MT180D, MT180H, MT180HD, MT210, MT210D, MT250, MT250D, MT300, MT300D — 1970s–1990s Precision Engineering Vault | Mitsubishi Tractor Service Repository.

- Calibrated Displacement Data: 776 cc (47.4 cu in) is specified as the K3A engine cylinder volume Baseline.

- Documented Power Output: For optimal performance, 11.6 kW (15.5 hp) is rated at the power take-off shaft threshold Framework.

- Nominal Compression Pressure: 3140 kPa (455 psi) establishes the engine combustion chamber pressure requirements Matrix.

- Primary Cooling Capacity: The cooling system requires 5.8 L (6.1 quarts) for Models MT160 through MT180 temperature control Specifications.

- Measured Transmission Volume: For transmission operation, 20 L (21.1 quarts) defines the main transmission fluid capacity Envelope.

- Injection System Pressure: 11,760 kPa (1,706 psi) is calibrated to the minimum injector opening pressure standard Parameters.

Professional Workshop Service Manual & Technical Specifications

Expert Configuration Manual: Mitsubishi Tractor Service Manual - Repair-Index

Conceptual-Layout: MT160, MT160D, MT180, MT180D, MT180H, MT180HD, MT210, MT210D, MT250, MT250D // Model-Specs: Multi-model diesel tractor system architecture / comprehensive service framework // Unit-Designations: Complete technical specification documentation for single-cylinder and three-cylinder diesel engines.

| Integrated-Framework | Technical-Path | Calibration-Standards |

|---|---|---|

| Engine assembly procedures with cylinder head, crankshaft, and timing systems | Detailed overhaul sequences for main and range transmissions | Bore specifications (65-78 mm), main journal diameters (52-57 mm), compression pressure data |

| Front and rear axle service for two-wheel and four-wheel drive models | Hydraulic system control valve and pump maintenance protocols | Bearing clearances (0.04-0.1 mm standard, 0.15 mm maximum allowable) |

| Differential and final drive gear servicing with bearing adjustment methods | Brake assembly disassembly and mechanical actuation procedures | Injection timing marks (21° BTDC standard, adjustable with shim selection) |

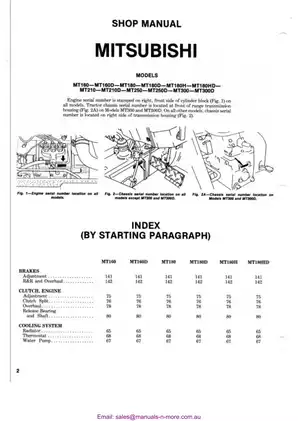

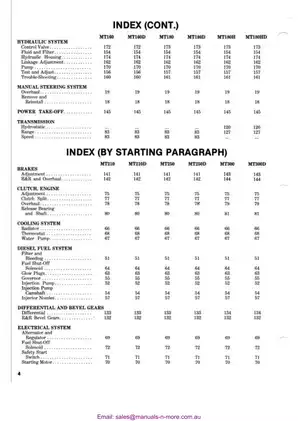

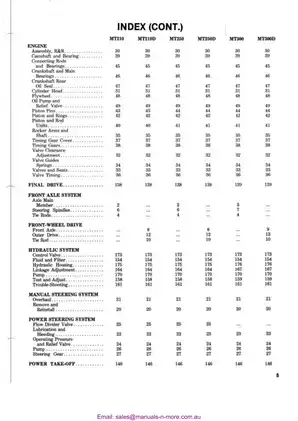

The documentation is partitioned into front axle assembly procedures, engine component service techniques, transmission and range gearbox overhaul instructions, differential lock mechanisms, and complete hydraulic lift system configurations.

Fuel system procedures are documented for injection pump timing adjustments, filter maintenance, fuel shut-off solenoid function, and glow plug testing protocols. Adjustment procedures are detailed for valve clearance settings (0.25 mm intake and exhaust on cold cylinder), governor linkage control speeds (900 rpm slow idle, 2700 rpm rated operation), and clutch pedal free play calibration (20-30 mm on smaller models, 10-25 mm on larger tractors). Timing procedures are documented for crankshaft gear alignment with injection pump camshaft marks, establishing proper valve events across the firing sequence (1-3-2 cylinder order). Technical notes are provided for hydrostatic transmission pressure testing (26000-28500 kPa forward circuit, 400-600 kPa charge circuit), bevel gear backlash measurement between ring gear and pinion (0.1-0.4 mm recommended clearance), and final drive oil seal installation with proper lip orientation. Quality checks are addressed for steering system worm shaft preload (0.4-0.6 N·m bearing preload for reassembled shafts), hydraulic pump output validation at engine rated speed, and differential carrier bearing end play adjustment to zero clearance.

The manual documents torque specifications for critical fastener assemblies to ensure proper bearing preload accuracy. Service data includes control valve spool clearance limits (0.03-0.079 mm piston bore clearance), power steering relief valve pressure settings (10275 kPa factory preset), and hydraulic lift system flow control valve lowering speed adjustment mechanisms. Detailed specifications cover piston ring groove wear limits (0.3 mm maximum side clearance), connecting rod bearing diametral clearance (0.04-0.1 mm standard operating range), and flywheel friction surface condition assessment criteria. The document provides dimensional reference tables for cylinder block bore measurements, crankshaft journal surface conditions after grinding operations, and valve seat width parameters (1.3-1.8 mm face and seat dimensions).

Organization: 76 pages of comprehensive service documentation organized by system function, including engine assembly and disassembly sequences, clutch and power transmission service methods, hydraulic control system maintenance, electrical system component testing, cooling system radiator and thermostat service, diesel fuel injection system procedures, and final drive brake mechanism overhaul instructions across multiple tractor model variants.

FAQ

Customer Reviews

Read what our customers say about this Mitsubishi Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews