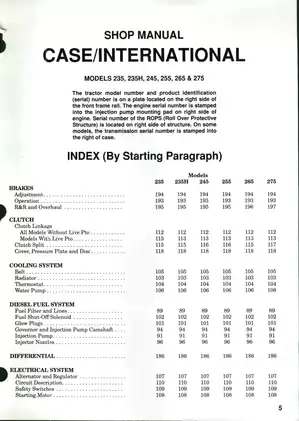

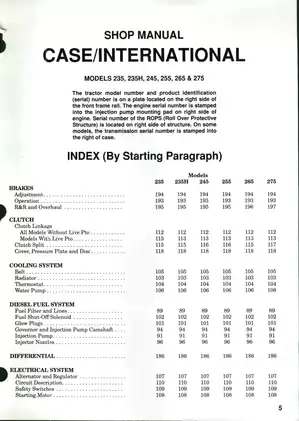

Case/International 235, 235H, 245, 255, 265 & 275 Tractor Shop Manual

Technician-level documentation for Case/International Tractors, covering all models: 235, 235H, 245, 255, 265 & 275 Tractors. Part No. Not Specified.

Manual Preview

Sample pages from the Case/International 235, 235H, 245, 255, 265 & 275 Tractor Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Case/International 235, 235H, 245, 255, 265 & 275

Shop Manual — For All Tractor Models

- Technical Resolution Data: 195 N⋅m torque specifications are found for the engine and clutch housing, ensuring proper operation and bolt stretch prevention.

- Specific Temperature Range: For optimal performance, 70 N⋅m torque is applied to the final drive housing bolts when separating the engine and clutch housing, ensuring correct assembly.

- Essential Power Rating: 82 N⋅m is used for the 12M screws, signifying the torque required for rear axle center housing and transmission housing connections.

- Advanced Memory Capacity: The manual specifies 25-29 N⋅m torque for the 8M screws, crucial for proper engine to clutch housing alignment.

- Core Speed Performance: Proper functioning is ensured by applying 55-75 N⋅m torque to the transmission to clutch housing and transmission to rear axle center housing retaining nuts.

- Engineered Torque: Tightening the hydraulic lines requires 3.9-6.9 N⋅m for pressure and pump inlet lines, ensuring correct fluid flow and application.

Professional Workshop Service Manual & Technical Specifications

Integrated Quality Installation Manual: Case/International Comprehensive 235, 235H, 245, 255, 265 & 275 Tractor Shop Manual Procedure-Library

Engineering-Base: Case/International // Technical-Benchmarks: Tractor / Tractor Logic // Engineering-Base: N/A.

| Performance-Element | Rating | Validation-Data |

|---|---|---|

| Manual Assembly | 25-29 N⋅m | Clutch housing screws set correctly. |

| Initial Torque Application | 55-75 N⋅m | Transmission housing connections ensured. |

| Hydraulic Line Torque | 3.9-6.9 N⋅m | Pressure and pump inlet lines lubricated. |

| Clutch Linkage Adjustment | 105-115 mm | PTO engagement lever correctly positioned. |

| Engine Clutch Torque | 82-92 N⋅m | Proper alignment of clutch disc and shaft. |

| Final Drive Housing Torque | 30-42 N⋅m | Axle housing assembly secured properly. |

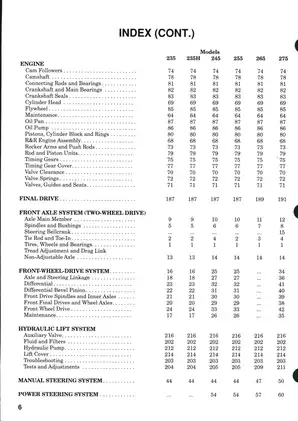

Systematizing the service groups into the following chapters:

- Clutch Linkage and Clutch Split

- Brakes: Adjustment, Operation, R&R and Overhaul

- Front Axle Systems and Steering Linkage

- Power Take-Off (PTO) - Rear Drive Shaft

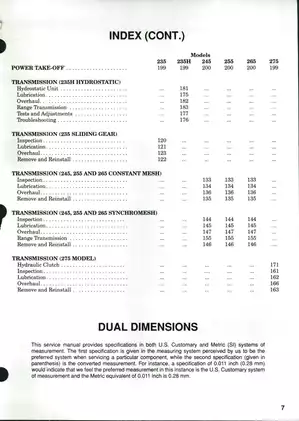

- Transmission (Synchromesh and Constant Mesh)

The document includes coverage of the main tractor systems, providing essential maintenance and repair procedures for optimal performance and longevity. Brake system specifications are included for all models, ensuring consistent and reliable stopping power. Safety procedures are documented to guide users through all repairs. Fluid capacities are listed for all models and systems, facilitating correct fluid levels for operation. Tool requirements are listed for specific procedures, ensuring proper execution of repairs.

FAQ

Customer Reviews

Read what our customers say about this Case Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews