Case Skid Steer Loaders 85XT / 90XT / 95XT Service Manual

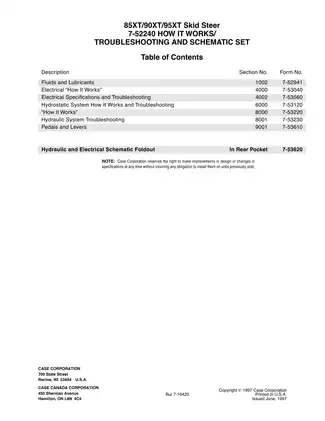

This manual provides comprehensive coverage for Case 85XT, 90XT, and 95XT skid steer loader models, detailing electrical systems, hydrostatic operations, and troubleshooting. Ref: 7-52240

Manual Preview

Sample pages from the Case Skid Steer Loaders 85XT / 90XT / 95XT Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Case 85XT, 90XT, 95XT Skid Steer Loaders Service Manual | 1997

Case 85XT, 90XT, 95XT (7-52240) – 1997 Fluids and Lubricants | Capacities Section

- Nominal Lubricant Capacity: 76.4 litres sets the primary fuel tank volume Requirements.

- Prescribed Fluid Specification: For optimal operation, Case No. 1 Engine Oil SAE 15W-40 (API service CG-4 or CF-4) defines the crankcase oil specifications Threshold.

- System Hydraulic Oil: The hydrostatic system requires 10W30 with HTO for standard operation Logic.

- Calibrated Chain Compartment Oil: For each side, 4.7 litres (5.0 quarts) specifies the necessary lubricant Configuration.

- Documented Gear Oil Capacity: The transmission housing specifies 66.2 litres (17.5 gallons) of oil Configuration.

- Defined Battery Electrolyte: For proper power, Distilled water is the specified electrolyte standard Benchmarks.

Professional Workshop Service Manual & Technical Specifications

Case 85XT, 90XT, 95XT Skid Steer Loader Diagnostics - Service & Repair Data-Compendium Manual: Case 85XT, 90XT, 95XT Skid Steer Loader Diagnostics - Service & Repair Data-Compendium

Model-Portfolio: Case 85XT / 90XT / 95XT // Machine-Range: Skid Steer Loader / Hydrostatic System Logic // Calibration-Scope: Electrical Systems & Schematics.

Service sections detail...

Hydraulic System Overview

Loader Control Valve

Self-Leveling Valve

Cylinders

Filtration and Cooling

Hydraulic Capacities and Lubricants

The Case XT Skid Steers are equipped with hydraulic systems that require specific fluids and lubrication for optimal operation. The manual documents lubrication specifications for various components, including engine crankcase oil, hydraulic system oil, and greases, to ensure proper function and longevity. The system includes detailed information on fluid capacities for the fuel tank, cooling system, hydraulic system, chain compartments, and engine crankcase. Furthermore, it outlines the environmental considerations for the disposal of these fluids.

Loader Control Valve Functions

The loader control valve assembly, a three-spool system, manages multiple hydraulic functions including loader lift, bucket curl/dump, and auxiliary circuits. It utilizes an open center configuration with oil ported in a series flow path. The valve incorporates a main relief valve and circuit relief valves to protect the system from over-pressurization. Details on spool actuation for various loader and bucket movements, such as raising, lowering, floating, curling, and dumping, are extensively covered. Special attention is given to the spool lock rod assembly and spool lock solenoid valve, which are integral to the control valve's operation and safety mechanisms.

Hydraulic Troubleshooting

This manual provides a systematic approach to troubleshooting common hydraulic system issues. It covers procedures for checking charge pressure/flow, analyzing test results, and testing circuit relief valve pressure. Specific sections address the 85XT and 90XT/95XT hydrostatic drive motors, planetary gear reducers, and parking brake assemblies. Troubleshooting guidance extends to hydrostatic control levers, self-leveling valves, and various hydraulic circuits, including high flow systems. The document emphasizes the importance of cleanliness in hydraulic systems to prevent contamination and costly damage.

Loader Spool Actuation and Control

Detailed explanations are provided for various loader spool actuations, including raising the loader, lowering the loader, and achieving float positions. Special attention is given to the "Loader Raise-Bucket Self-Leveling" and "Loader Raise-Bucket At Full Dump" scenarios, illustrating how the self-leveling circuit maintains bucket level. The "Loader Lowering" sequence and "Loader Spool Actuated to Curl" are also explained, clarifying the oil flow paths and the function of check valves. The manual details the "Spool Lock Rod Assembly" and "Spool Lock Solenoid Valve," crucial components for maintaining neutral spool positions and ensuring safety during operation.

The manual also covers the adjustment of the throttle control linkage, loader control linkage, attachment mechanical couplers, auxiliary hydraulic pedal, and the high flow/high pressure control lever. These sections provide step-by-step instructions to ensure proper mechanical alignment and operation of these critical control systems. It references specific measurements and torque values where applicable, such as the 102.5 mm (4.04 inch) compressed spring length for attachment coupler adjustment.

FAQ

Customer Reviews

Read what our customers say about this Case Skid Steer Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)