Eina 2003 / 2005 / 2007 Sewing Machine Service Manual

Comprehensive diagnostic and repair procedures for Eina sewing machines, models 2003, 2005, and 2007. Includes detailed diagrams and troubleshooting steps. PN 395902-72.

Manual Preview

Sample pages from the Eina 2003 / 2005 / 2007 Sewing Machine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Comprehensive Diagnostic Hydraulic Manual: Eina Model 2003, 2005 & 2007 Sewing Machine Service Manual - Precision Troubleshooting & Repair Calibration-Manual Eina Model 2003, 2005 & 2007 (395902-72) -- 2003-2007 Diagnostic Vault for Sewing Machine | Package. Designated Imaging Specs: 1.0-1.2 mm establishes the needle plate to presser foot distance Requirement. Verified Coupling Torques: 15 kg/cm signifies the torque for the needle bar clamp screw Configuration. Nominal Fill Levels: 110-130 g is configured at for standard needle thread tension Benchmarks. Design Assembly Gap: 0–0.15 mm is established at for needle and shuttle hook clearance Parameters. Engineered Ambient Limits: 5-6.5 mm defines the needle swing clearance Requirement. Essential Precision Specs: 3.2 mm signifies the shuttle point to needle clearance Range.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Diagnostic Hydraulic Manual: Eina Model 2003, 2005 & 2007 Sewing Machine Service Manual - Precision Troubleshooting & Repair Calibration-Manual

Asset-ID: Eina 2003, 2005, 2007 Sewing Machine / Electronic Logic // Application-Range: Service Manual / Sewing Machine Logic // Equipment-Series: 395902-72 Technical-Details.

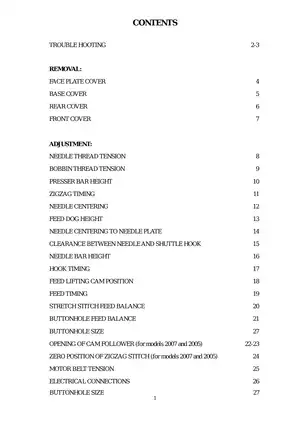

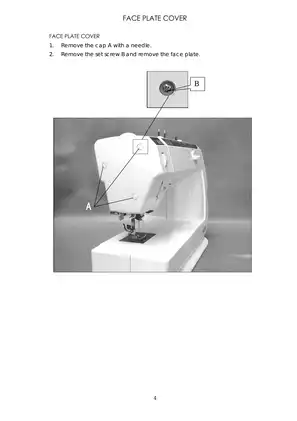

Suspension service documentation covers a wide array of adjustments and component removals, including face plates, base covers, rear panels, and front covers, facilitating thorough machine maintenance. Disassembly instructions are documented for critical components, guiding users through the process of accessing internal mechanisms for inspection and repair. Wear limits are specified for various parts, ensuring that components are within operational tolerances to maintain optimal performance and longevity. System operation descriptions cover electrical connections for both 120V and 230V models, providing clear schematic diagrams for technicians. The documentation addresses troubleshooting common issues such as skipping stitches, machine noise, and distorted stitch patterns, offering specific remedies for each problem.

| Assessment-Element | Baseline | Framework |

|---|---|---|

| Needle Thread Tension | 110-130 g | Standard |

| Bobbin Thread Tension | 25-30 g | Standard |

| Presser Bar Height | 6.5-6.8 mm | Standard |

| Zigzag Timing | 5-6.5 mm | Clearance |

| Hook Timing | 3.2 mm | Clearance |

| Feed Dog Height | 1.0-1.2 mm | Adjustment |

This manual details adjustments for needle thread tension, bobbin thread tension, presser bar height, zigzag timing, hook timing, and feed dog height. It also documents procedures for buttonhole adjustments and motor belt tensioning, crucial for maintaining sewing quality. Correctly demanding proper maintenance and accurate adjustments, this manual aids in the professional upkeep of the Eina sewing machines.

Torque specifications for various adjustments, such as the needle bar clamp screw, are documented to ensure proper assembly and prevent joint corrosion.

FAQ

Customer Reviews

Read what our customers say about this Elna Sewing Machine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)