New Holland LS160 and LS170 Skid Steer Service Manual

Product Gallery

Sample pages from the New Holland LS160 and LS170 Skid Steer Service Manual manual

Purchase Information

New Holland LS160 and LS170 Skid Steer Service Manual - Technical Specifications

- File Size:

- 11.08 MB

- File Type:

- Language:

- English

- Pages:

- 741

- Printable:

- Yes

- Estimated Download Time:

- 0.23 Minutes

- Delivery Format:

- Digital (PDF) - Instant Access

- Category:

- Skid Steer Loader

- Brand:

- New Holland

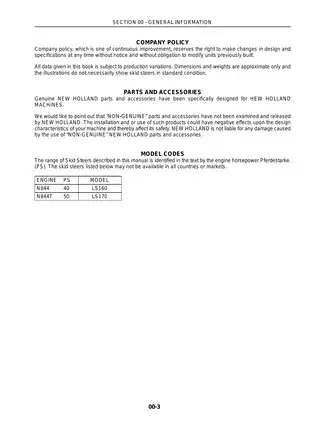

New Holland Models and Parts Covered in this Skid Steer Loader Manual

- LS160

- LS170

New Holland New Holland LS160 and LS170 Skid Steer Service Manual - Complete Manual Information

New Holland LS160 and LS170 Skid Steer Service Manual

Ensure your New Holland LS160 or LS170 skid steer operates at optimal performance with our comprehensive service manual. This guide is meticulously crafted to provide you with detailed instructions, essential safety information, and specifications crucial for the maintenance and operation of your equipment. Designed for both experienced mechanics and novice users, this manual is your go-to resource for troubleshooting and repair.

Why You Need This Manual

The New Holland LS160 and LS170 service manual includes:

- Step-by-step instructions for disassembly and reassembly of the engine and components.

- Detailed diagrams and specifications for each model.

- Safety precautions and operational guidance to minimize risks.

- Maintenance schedules to ensure longevity and reliability.

What's Inside

- Introduction to General Information: Understanding the skid steer operational mechanics and safety.

- Engine Specs and Maintenance: Includes torque specifications, parts locations, and maintenance tips for the N844 and N844T engines.

- Fuel System Management: How to properly handle and maintain the fuel system for reliable operation.

- Hydraulic System Overview: Details on maintaining and repairing the hydraulic system components.

- Engine Troubleshooting: A detailed section on diagnosing and fixing common engine issues.

Investing in this manual will not only save you time on repairs but also provide insights into optimizing the performance of your skid steer.

Stay prepared and ensure your machine runs smoothly with the New Holland LS160 and LS170 Service Manual!

Download Instructions for New Holland Skid Steer Loader Manual

Frequently Asked Questions - New Holland Skid Steer Loader Manual

What does this New Holland manual cover?

This comprehensive service manual covers detailed repair procedures, maintenance schedules, troubleshooting guides, and technical specifications for New Holland LS160 and LS170 Skid Steer Service Manual. It includes information for the following models: - LS160 - LS170.

Is this manual suitable for beginners?

Yes, this New Holland manual is designed for both professional technicians and DIY enthusiasts. It includes step-by-step procedures with clear illustrations and safety guidelines for Skid Steer Loader maintenance and repair.

What file format will I receive?

You will receive this manual as a PDF file (11.08 MB), which is compatible with all devices. The manual is fully searchable and printable for your convenience.

How quickly can I access the manual after purchase?

You'll receive instant access to your New Holland Skid Steer Loader manual immediately after payment completion. The download link is valid for 3 days, with lifetime re-download guarantee.

Can I print specific sections of the manual?

Absolutely! This digital manual allows you to print any section you need, from individual pages to complete chapters, making it perfect for workshop use.

New Holland New Holland LS160 and LS170 Skid Steer Service Manual Customer Reviews and Feedback

Read what our customers say about this New Holland Skid Steer Loader manual and share your own experience.

Add Comment

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Comments (2)