Mustang Loader 940 Series 1994 Parts Catalog (160 P.)

Complete parts list for Mustang 940 Series loader — frame, hydraulic systems, engine components, and attachments. Publication 000-34884, revised January 1994.

Manual Preview

Sample pages from the Mustang Loader 940 Series 1994 Parts Catalog (160 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Mustang Loader 940 Series — 1994 Diagnostic & Technical Library | 940 Series Folder.

- Verified Imaging Specs: 2325 psi is measured at the main relief valve setting for hydraulic system pressure Architecture.

- Key Coupling Torques: For optimal performance, the fastening specifications are set to standard grade mechanical fasteners Norms.

- Prescribed Fill Levels: Hydraulic fluid capacity limits 14.5 gallons (84 liters) to maintain system efficiency Bounds.

- Nominal Assembly Gap: The cylinder bore requires 2.5 inches (63.5 mm) for standard lift cylinder operation Topology.

- Design Ambient Limits: Operating temperature range maintains -4°C to +49°C (25°F to 120°F) environmental tolerance Matrix.

- Designated Precision Specs: Tire specification controls 7.00 x 15 inches (177.8 x 381 mm) dimension standards Standards.

Professional Workshop Service Manual & Technical Specifications

Structured Procedure Safety Manual: Loader Mustang Loader 940 Series 1994 - Comprehensive Parts Manual and Repair Procedures Specification-Guide

Repair-Classification: Mustang Loader 940 Series (1994) // Technical-Domain: Hydraulic and mechanical system documentation // Repair-Classification: Complete component and assembly reference with serial-number tracking.

| Assessment-Parameter | Diagnostic-Logic | Framework |

|---|---|---|

| Frame and Lift Arm Systems | Main frame, lift arm, Fast-A-Tach components documented across serial ranges | See Page 4 |

| Drive System Components | Axle drive, brakes, steering controls, hydraulic motors referenced in complete assemblies | See Pages 16-30 |

| Engine Assembly Documentation | Yanmar 4TN82E engine blocks, cylinder heads, fuel injection systems with component breakdowns | See Pages 80-109 |

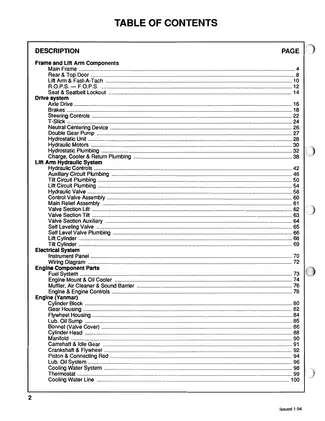

Organized into dedicated modules for the lift arm and attachment systems, the document covers main frame configurations, R.O.P.S./F.O.P.S. protective structures, and seat belt lockout mechanisms, while addressing the drive system through axle drive assemblies, brake specifications, and steering control arrangements. Completely requiring technical reference for the hydrostatic unit, charge cooler plumbing, and auxiliary circuit documentation, the manual encompasses hydraulic motors, lift and tilt circuit plumbing systems, and comprehensive valve section assemblies. Engine rebuild procedures are documented for the Yanmar diesel engine, addressing cylinder block, gear housing, flywheel housing, camshaft idle gear, crankshaft flywheel, piston and connecting rod assemblies. Drivetrain specifications are addressed in the axle drive section with cluster sprocket configurations, idler arm assemblies, and brake system layouts. Reassembly procedures are specified for the lift and tilt cylinders with seal repair kits and hydraulic line assemblies. Service intervals are documented for lubrication systems, cooling water circuits, thermostat assemblies, and fuel injection pump components.

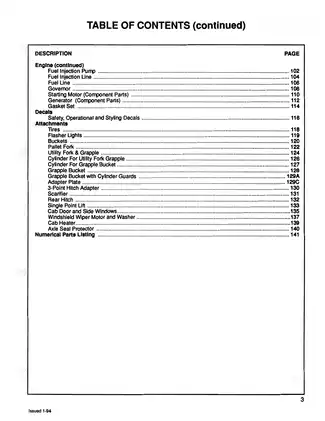

Factory specifications are documented for fuel system components including fuel tanks, filters, and injection line assemblies across multiple serial production ranges. Engine rebuild procedures are documented for fuel injection pump assemblies, governor mechanisms, starting motor component parts, and generator assemblies with detailed breakdowns. Drivetrain specifications are addressed through the hydraulic control systems, including pedal controls, tilt pedal arms, and auxiliary control linkages. Reassembly procedures are specified for the self-leveling valve plumbing and control valve assemblies with main relief valve configurations. Service intervals are documented for hydraulic fluid capacity, pressure settings, and coolant specifications across serial number ranges from 8403244 through 4463044.

The document includes extensive attachment options ranging from standard earth and foundry buckets in cubic foot capacities to specialized utility forks and grapple bucket systems with hydraulic cylinder assemblies. Pallet fork mounting frames, adapter plates, three-point hitch adapters, and scarifier components are documented with corresponding installation specifications. Cab enclosure packages containing door assemblies, side windows, windshield wiper motors, and cab heater systems reference mounting brackets, electrical harnesses, and control cable routing. Tire options include steel-capped chevron tread, terra-tire flotation, and sure grip configurations mounted on corresponding rim specifications. The manual provides torque specifications for bolt assemblies to ensure proper mechanical fastener integrity.

Decal sets covering safety operational styling and instruction warnings are documented in complete kits with individual component part numbers and placement references. Numerical parts listing organized by reference number and page location enables systematic identification and ordering of every component throughout all production variations and serial ranges.

FAQ

Customer Reviews

Read what our customers say about this Mustang Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)