1977-1981 Yanmar YM135 / YM155 / YM195 / YM240 / YM330 Shop Manual

Addresses transmission, hydraulic lift, and differential systems. Complete technical guide for YM135D, YM155D, YM195D, YM240D, YM330D variants.

Manual Preview

Sample pages from the 1977-1981 Yanmar YM135 / YM155 / YM195 / YM240 / YM330 Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yanmar YM135, YM135D, YM155, YM155D, YM195, YM195D, YM240, YM240D, YM330, YM330D — 1977–1981 Operational Registry Handbook | Tractor Service File.

- Engineered Fluid Capacity: The cooling system is calibrated to 4.1–8.2 L (1.08–2.16 US gal) depending on model architecture Mapping.

- Defined System Fill: For optimal lubrication, transmission and rear axle combined capacity supports 3.0–8.5 L (0.79–2.25 US gal) Configuration.

- Standard Assembly Gap: Valve tappet clearance establishes 0.20 mm (0.008 in) specification cold lash setting Benchmarks.

- Principal Ambient Limits: Operating envelope is designed for 15–35°C (59–95°F) ambient temperature Range.

- Advanced Dimensional Limits: Rotor type oil pump outer rotor to body bore clearance is specified as 0.100–0.108 mm (0.0039–0.0043 in) Sequences.

- Verified Locking Torques: Cylinder head retaining fasteners define 110–150 N·m (81–111 lbf·ft) tightening requirement Baseline.

Professional Workshop Service Manual & Technical Specifications

Precision Troubleshooting Assembly Manual: Tractor Yanmar YM135, YM135D, YM155, YM155D, YM195, YM195D, YM240, YM240D, YM330 and YM330D tractor shop manual, 1977-1981 edition Library-Master

Repair-Classification: YM135, YM135D, YM155, YM155D, YM195, YM195D, YM240, YM240D, YM330 and YM330D tractor series // Operational-Scope: Complete service and assembly logic for compact agricultural tractors // Documentation-Type: Comprehensive factory specifications and technical procedures.

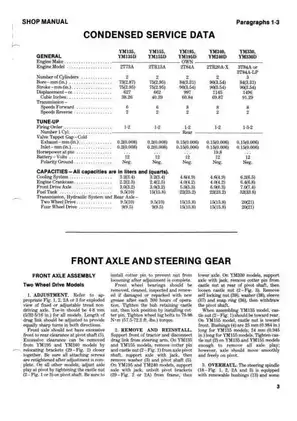

| Specification | Baseline | Logic |

|---|---|---|

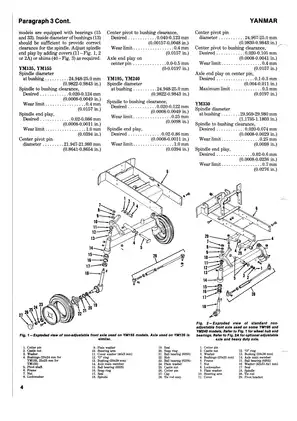

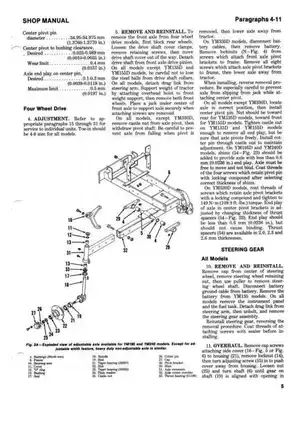

| Front Axle Assembly | Two-wheel and four-wheel drive configurations | Exploded diagrams with spindle, bushing, and bearing clearances documented |

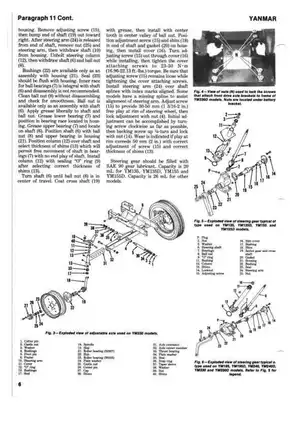

| Steering Gear System | Ball nut and column mechanisms | Adjustment procedures and wear limit specifications provided |

| Differential and Bevel Gears | YM135/YM155 two-cylinder and YM330 three-cylinder models | Complete mesh position and backlash documentation |

Systematizing the service groups into Front Axle Assembly connects Steering Gear mechanisms, addresses Differential systems and Bevel Gears, involves Transmission components and Final Drive housings, and encompasses Hydraulic Lift assemblies and Brake configurations. The service manual covers comprehensive engine systems documentation, incorporates powertrain specifications for clutch and transmission operations, provides front wheel drive and power takeoff service procedures, and examines hydraulic and electrical component maintenance protocols.

Technically calling for extensive disassembly and overhaul procedures, the document includes specifications for valve clearance adjustment on all cylinder configurations, documents torque specifications for the engine fastening hardware to ensure proper bearing preload accuracy, and presents detailed specifications across frame systems and component assemblies. Factory specifications are documented for engine rebuild procedures including cylinder head retaining sequences, camshaft journal diameters, and piston ring gap clearances across each model variant. Engine rebuild procedures are documented for connecting rod alignment, crankshaft bearing installation, and flywheel retention on both two- and three-cylinder variants. Drivetrain specifications are addressed in comprehensive sections covering clutch unit assembly, transmission gear train configurations, and differential carrier bearing installation requirements. Reassembly procedures are specified for final drive housing orientation, bevel gear mesh positioning, and rear axle seal installation with directional notation. Service intervals are documented for hydraulic system maintenance, brake drum inspection, and cooling system capacity requirements across the complete model line.

The manual documents specifications for valve seat width and intake port orientation to establish proper fuel atomization parameters. The publication provides exploded diagrams and cross-sectional drawings for engine, transmission, final drive, and hydraulic system assemblies. Specifications include measurement data for bore dimensions, journal diameters, clearances between components, and wear limit thresholds for all critical service areas. Tables and reference charts present condensed service data, capacity specifications, tune-up parameters, and component identification information by model series and engine designation. Wiring diagrams are included showing electrical circuit configuration for starter safety switches, alternator regulation circuits, and lighting systems.

The framework encompassing this manual presents systematic coverage of all major tractor systems in a strategic approach. The document addresses both routine maintenance operations and complete overhaul procedures for engines, clutches, transmissions, hydraulic systems, and steering mechanisms. Factory specifications control torque values for fasteners, bearing preload, hydraulic system relief pressures, and component adjustment parameters. Complete specification sections provide dimensional data for component wear evaluation and replacement criteria. Technical data sections cover the condensed service information, operating capacities, and service procedures organized by major system function.

FAQ

Customer Reviews

Read what our customers say about this Yanmar Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)