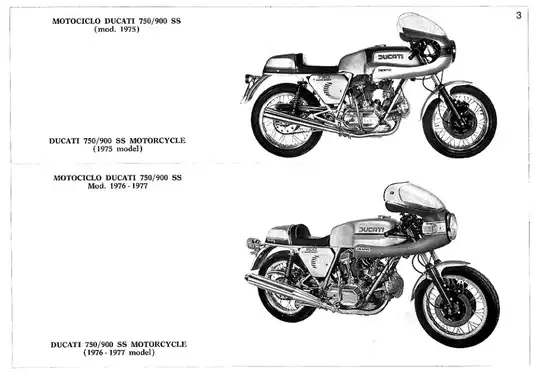

1975-1977 Ducati 750 SS / 900 SS Workshop Manual

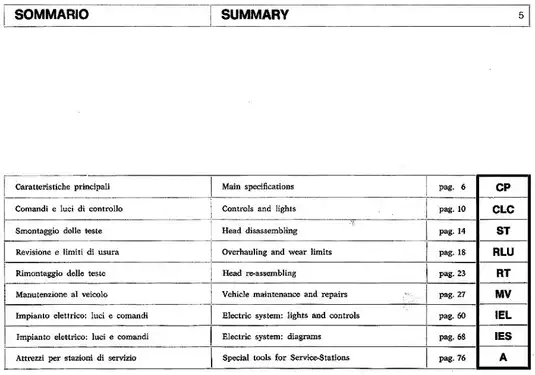

Wiring diagrams, specifications, and repair sequences for Desmo-equipped Italian sportbikes. Complete head disassembly, suspension service, and carburetor settings. PN 0797.80.343

Manual Preview

Sample pages from the 1975-1977 Ducati 750 SS / 900 SS Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Ducati 750 SS & 900 SS — 1975–1977 Technical Service Manual | 750/900 SS Motorcycle Unit.

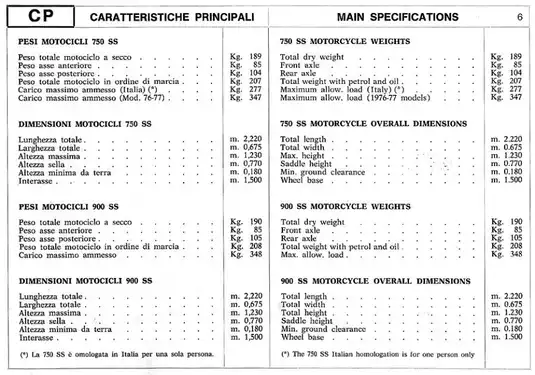

- Established Shipping Weight: 189 kg is measured at the dry motorcycle frame structure Margin.

- Reference Print Quality: The 900 SS represents 190 kg total mass without fuel Architecture.

- Essential Assembly Torques: Head bolts require 3.4–2.43 Kgm (24.6–31.1 ft/lb) established fastening Protocol.

- Baseline Adjustment Range: Fuel tank capacity is set to 18 L (4.8 US gal) with 2 L reserve Norms.

- Integral Generation Capacity: The twin-cylinder engine produces 90° L configuration at 4-stroke cycle Bounds.

- Specific Form Factor: Wheel base reaches 1,500 m (59 in) for both 750 and 900 models Topology.

Professional Workshop Service Manual & Technical Specifications

Strategic Safety Field Manual: Bike Complete Service Handbook: Ducati 750 SS & 900 SS (1975-1977) Standards-Vault

Series-Validation: Ducati 750 SS (1975-1977), Ducati 900 SS (1975-1977) // Component-Focus: Engine and transmission systems, electrical and brake circuits // Series-Validation: Bilingual service documentation (English, Italian), 76-page workshop resource.

| Specification | Rating | Validation-Data |

|---|---|---|

| Document Type | Service Manual | Complete technical procedures documented |

| Coverage Scope | Frame, engine, transmission, electrical | All major systems included |

| Model Years | 1975–1977 | Multiple variant configurations covered |

| Language Support | English / Italian | Parallel text throughout |

| Technical Diagrams | Wiring schematics, assembly drawings | 4 electrical system diagrams provided |

The service manual covers engine and transmission specifications, head disassembly procedures, suspension examination instructions, and frame inspection protocols. Additionally, it documents brake system maintenance guidance, chain tension adjustment methods, and fuel system operation details. Furthermore, the handbook includes electrical system wiring diagrams, carburetor adjustment references, and component identification tables. Finally, vehicle maintenance procedures are outlined for both front and rear wheel removal, swinging arm servicing, and tappet clearance verification.

Precise Interface

Repair information is provided for cylinder head assembly and valve train configurations, detailing the Desmo distribution system with upper and lower rocker mechanisms. The document includes coverage of main bearing specifications, camshaft positioning, and valve guide replacement procedures with dimensional references. Brake system specifications are included for both disc brake calves and hydraulic pump assemblies across different model years.

Technical Framework

Safety procedures are documented for frame inspection and suspension service intervals. The manual outlines head removal and reassembly sequences with specific component ordering, tool requirements, and bearing installation methods. Fluid capacities are listed for fuel tank volume and hydraulic system components, with carburetor float chamber specifications and pump delivery measurements provided for both PHM/40 and PHF/32 carburetor variants.

Technical Threshold

The document provides detailed wiring diagram schemas for 1975 and 1976–1977 model configurations, including electrical system operation modes, switch positions, and circuit protection specifications. Reference data encompasses torque specifications for engine fasteners, covering head bolt tightening values, flywheel and pinion retention methods, and clutch drum assembly procedures to ensure proper fastener security.

Engineered Nexus

Component listings accompany suspension examination protocols, detailing bushing clearance tolerances and pivot pin specifications. The handbook documents specifications for wheel assembly configurations, including rim dimensions, bearing sizes, and brake disc diameters with caliper positioning details. Exhaust system component identification and chain dimension specifications are included throughout.

Structured Logic-Path

The document illustrates desmo-type valve train assembly sequences with photographic and diagrammatic references. An uprating kit section catalogs performance modification components, including high-flow carburetor jets, racing camshaft options, and enhanced exhaust system configurations for competition use. Specialized service tool requirements are documented at the conclusion, providing part numbers and functional descriptions for head work, bearing extraction, and timing system maintenance procedures.

FAQ

Customer Reviews

Read what our customers say about this Ducati Bike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)