Komatsu PC27-45MRX Excavator Shop Manual 965 Pages

PC27MRX–PC45MRX service documentation with complete hydraulic system, engine specifications, and component rebuild procedures. Document ID: SEBM016808

Manual Preview

Sample pages from the Komatsu PC27-45MRX Excavator Shop Manual 965 Pages manual

Purchase & Download

Models Covered & Key Technical Specifications

Komatsu PC27MRX-1, PC30MRX-1, PC35MRX-1, PC40MRX-1, PC45MRX-1 (11574+, 10001+, 3930+, 1001+, 1001+) — 2003 Applied Professional Repository | MRX Series Catalog.

- Calibrated Displacement Data: 1.490 liters (1,496 cc) is measured at the 3D84E-3 engine cylinder volume Specifications.

- Factory Power Output: 20.6 kW at 2,500 rpm represents the maximum rated horsepower Framework for PC30MRX-1 configuration.

- Primary Torque Specification: 85.3 N·m (8.7 kgm) at 1,800 rpm is established at peak crankshaft output Norms.

- General Hydraulic Capacity: The main control valve requires 26.3 ± 0.49 MPa (268 ± 5 kg/cm²) relief pressure set for standard operation Logic.

- Essential Operating Temperature: Cooling water temperature reaches maximum 120°C (248°F) for optimal engine performance Parameters.

- Operational Track Tension: The undercarriage assembly produces 9.3 rpm swing speed for standard boom swing operation Bounds.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Safety Technical Manual: Mini Excavator Complete Komatsu PC27MRX Excavator Shop Manual (SN 11574+) (926 P.) | Pro Service File Service-Dossier

Diagnostic-Area: PC27MRX–1, PC30MRX–1, PC35MRX–1, PC40MRX–1, PC45MRX–1 Series (SEBM016808) // Technical-Scope: Hydraulic system architecture, engine configuration, and work equipment logic // Engineering-Base: Comprehensive factory documentation covering 947 pages of technical specifications and service procedures.

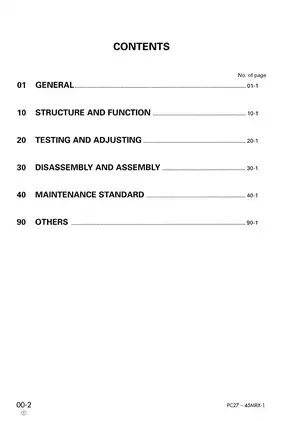

Engineering chapters address engine and transmission systems, calling for swing and travel assemblies, while containing boom and arm hydraulic configurations. The document encompasses fuel system data, cooling logic specifications, and lubrication architecture for the complete 3D82AE-3, 3D84E-3, and 4D84E-3 engine platforms. Hydraulic schematics are included for the complete closed-center load sensing system (CLSS) with variable displacement piston pump and multi-stage pressure compensation valve network. Steering component information is provided for the travel motor assembly, swing machinery architecture, and final drive transmission systems across all model variants. Assembly instructions are detailed for swing motor brake actuation, hydraulic cylinder rod seal replacement, and center swivel joint slipper seal installation procedures. Inspection guidelines are provided for track shoe tension adjustment, sprocket wear measurement using gauge alignment, and swing circle bearing inspection protocols. Alignment specifications are included for fuel control lever positioning, boom swing pedal travel calibration, and work equipment control lever stroke standardization.

The manual documents torque specifications for mounting fasteners, seal head assembly bolts, and hydraulic component connections to ensure proper assembly integration. Reference chapters include electrical wiring diagrams for all five model configurations, connector pin allocation drawings with male and female housing configurations, and machine monitor system displays covering coolant temperature gauges, fuel level sensors, and caution lamp circuits. Complete structure information identifies 12 major system chapters including general assembly data, engine control circuits, hydraulic piping layouts, valve control schematics, and troubleshooting flowcharts organized by electrical, hydraulic, and mechanical failure modes.

| Metric | System-Path | Calibration-Data |

|---|---|---|

| Engine Architecture | 3D82AE-3 / 3D84E-3 / 4D84E-3 Framework | Specifications documented in dedicated engine chapter |

| Hydraulic Capacity | Fuel tank: 44 liters; Oil pan: 5.3–7.2 liters | Complete capacity tables provided |

| Performance Data | Boom reach: 5,300 mm; Digging force: 28.5 kN | All specifications in working ranges section |

| Travel Parameters | Speed range: 2.6–4.6 km/h across gear ratios | Load-sensing system controls documented |

| System Integration | Swing machinery reduction ratio: 8.09–7.8 | Wiring and hydraulic interconnection diagrams included |

FAQ

Customer Reviews

Read what our customers say about this Komatsu Mini Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)