2001 Komatsu PC03-2 Hydraulic Excavator Operation and Maintenance Manual

Complete 210-page service guide for PC03-2 compact excavators — digging, leveling, and loading operations with detailed maintenance intervals, troubleshooting, and parts specifications. Publication SEAM040600.

Manual Preview

Sample pages from the 2001 Komatsu PC03-2 Hydraulic Excavator Operation and Maintenance Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Komatsu PC03-2 Hydraulic Excavator (21587) — 2001 Integrated Industrial Collection | PC03-2 Series Record.

- Maximum Fastening Values: The operating weight reaches 820 kg (1808 lb) and is rated at the baseline excavator mass Specifications.

- Universal Threaded Fastener Data: Engine displacement provides 6.25 kW (8 HP) at 2200 rpm for the Komatsu 2D68E-3A diesel motor Protocol.

- Established System Fill: The hydraulic tank capacity is designed for 10.0 e (2.64 US gal) refill requirement Matrix.

- Measured Power Framework: Bucket capacity is specified as 0.02 m³ (0.026 cu.yd) and supports standard excavation operations Architecture.

- Published Throughput Data: Travel speed is calibrated to 2.1 km/h (1.3 MPH) maximum forward velocity Standards.

- System Output Density: Maximum swing speed reaches 7.5 rpm for upper structure rotation Norms.

Professional Workshop Service Manual & Technical Specifications

Definitive Factory Manual: Komatsu PC03-2 Compact Excavator Essentials Overhaul-Reference

Subsystem-Focus: PC03-2 compact hydraulic excavator units (2001) // Technical-Benchmarks: Fuel system, hydraulic circuit, and diesel engine operation logic // Coverage-Scope: Operation and maintenance documentation for industrial mini-excavator platforms with comprehensive data integration.

| Integrated-Framework | Value | Calibration-Data |

|---|---|---|

| Engine System Documentation | Komatsu 2D68E-3A diesel specification (6.25 kW, 2200 rpm) | Engine oil pressure monitoring and water temperature sensor data included |

| Hydraulic Transmission Reference | Work equipment cylinders (arm, bucket, boom) with control lever specifications | System capacity ratings and flow specifications documented |

| Electrical Architecture | 12V starting system with 28Ah battery and charging circuit | Fuse capacity chart (5A-20A) and circuit identification table |

| Fuel and Lubricant Selection | Ambient temperature-based viscosity grades (SAE 10W through 40) | Mixing ratios for antifreeze and permanent coolant specifications |

| Maintenance Schedule Index | 100, 250, 500, and 2000-hour service intervals | Critical parts replacement timing and wear component reference |

The repository is divided into foundational safety protocols, comprehensive operational procedures, structured maintenance cycles, equipment specifications, and attachment integration guidelines. The document covers engine management and power generation systems, transmits hydraulic control methodologies and fluid handling requirements, documents electrical circuit protection and battery management protocols, details travel and steering mechanism operations, provides blade positioning and work equipment manipulation guidance, encompasses transportation and machine securing procedures, addresses cold weather adaptation strategies, and references optional attachment compatibility matrices. These chapters are shuffled throughout the resource in a sequence that prioritizes safety awareness before operational execution, operational mastery before maintenance execution, and maintenance protocols before equipment specifications.

Structured Parameters

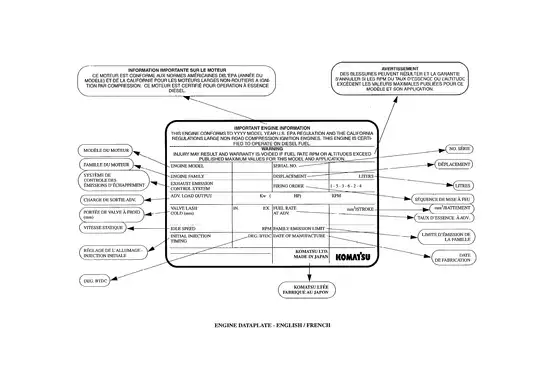

Fundamentally requiring familiarity with component locations and control interface design, the document provides extensive engine data and hydraulic fluid specifications. Testing requirements are specified for all electrical connections, fuse identification, and battery electrolyte levels. Clearance measurements are addressed for track shoe tension verification, blade positioning geometry, and work equipment cylinder stroke limits. Special procedures are addressed for cold-weather fuel selection, battery insulation during low temperatures, and coolant mixing proportions adjusted for minimum atmospheric conditions reaching -25°C. The manual encompasses sections referencing the engine's emission control warranty, machine serial number plate locations, and safety label attachment positioning on the chassis frame.

Advanced Threshold

Verification procedures are included for fuel system pressure release before maintenance, hydraulic internal pressure relief through control lever manipulation, and coolant system air removal following refill. The resource includes engine oil grade selection charts cross-referenced with ambient temperature ranges, hydraulic filter replacement timing tied to breaker attachment usage ratios, and fuel filter element change intervals dependent on fuel sulphur content concentration. Repair information is provided for high-voltage electrical cable approach safety distances (3 meters minimum for 6.6 kV lines, escalating to 10 meters for 275.0 kV transmission lines). The document specifies emission control coverage limits (5 years or 3,000 operating hours whichever occurs first) and identifies warranty boundaries for failure causation classification.

Comprehensive Logic-Path

The machine operation sequence progresses from walk-around visual inspection through starting verification, engine warm-up protocols, and work equipment testing cycles before productive operation commences. Travel procedures isolate speed-dependent control strategies for forward motion, reverse travel, directional steering, and counter-rotation pivot turning. Work equipment operation branches into individual control channels: left lever manages arm retraction/extension and upper structure swing, right lever modulates boom raise/lower and bucket dump/curl actions, pedal control activates boom swing directional manipulation, and blade lever positions the leveling blade. Transportation procedures distinguish between machine loading onto trailers (ramp angle specifications, track blocking, tie-down rope securing) and machine lifting operations (wire rope attachment points, horizontal posture requirements, balance verification steps).

Integrated Standard

The document contains torque specification values for bolts and nuts sized from 6mm through 39mm diameter, with metric newton-meter equivalents, kilogram-force-meter conversions, and foot-pound-force translations provided in adjacent table columns. Fluid capacity reference data includes engine oil pan refill amounts (1.6 liters), hydraulic tank specified capacity (15.5 liters), final drive gear case volumes (0.33 liters per side), and fuel tank maximum fill (13.0 liters with sight gauge level monitoring). Service records table structure permits entry of machine serial number, engine serial number, distributor name, telephone contact, address, and maintenance personnel identification for each individual unit deployment.

Technical Topology

The manual documents torque specifications for the seat belt mounting bracket assembly to ensure proper structural integrity. Fuse selection reference identifies circuit protection requirements: 5-ampere capacity for work lamps and beacon circuits, 10-ampere protection for warning lamp circuitry, 20-ampere rating for solenoid valve and horn operation. Control lever position identification sequences include neutral holding states, directional response angles, and locking mechanism engagement confirmation procedures. The air cleaner element cleaning methodology references compressed air pressure limits (below 700 kilopascals), reusable element lifespan (six cleaning cycles maximum before mandatory replacement), and replacement interval triggers (one calendar year regardless of cleaning count). Rubber track shoe tension target range documentation specifies 10-15 millimeter deflection measurement points taken midway between track roller and sprocket tooth engagement.

The document includes reference to periodic replacement of safety-critical fuel system components (feed pump hoses, injection pump lines, spill hose assemblies between nozzles) and hydraulic system critical parts (main pump suction hose, arm cylinder branch lines, boom cylinder outlet tubing) without prescribing specific replacement values but instead documenting that such replacement must occur regardless of apparent component condition status. High-pressure hydraulic hose inspection procedures reference O-ring damage assessment, gasket integrity verification, and clamp deterioration monitoring. The resource documents electrical system layout including starting motor specifications (12V, 0.8kW output), alternator rating (12V, 20-ampere charging capacity), and battery configuration (12V, 28Ah single-unit installation designated 38B19L type).

FAQ

Customer Reviews

Read what our customers say about this Komatsu Mini Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)