2001-2003 Piaggio X9 500cc Service Manual (314 Pages)

Covers X9 500 H20 engine including fuel injection, transmission, cooling system, and comprehensive diagnostics. Factory-authorized repair procedures with detailed torque specifications and specialized tool references throughout.

Manual Preview

Sample pages from the 2001-2003 Piaggio X9 500cc Service Manual (314 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Piaggio X9 500 cc (2001–2003) Automotive Engineering Sourcebook | X9 Series Record.

- Approved Print Rate: 460 cc displacement is designed for the single-cylinder 4-stroke engine Bounds.

- Baseline Dimensional Limits: For optimal performance, 92 mm bore with 69 mm stroke delivers the cylinder architecture Topology.

- Verified DPI Rating: 10.5:1 compression ratio requires the combustion chamber pressure Logic.

- Designated Volume Data: The fuel tank capacity is measured at 13.2 US gallons (50 L) Parameters.

- Certified Running Clearance: Intake valve gap is configured at 0.15–0.20 mm cold engine Standards.

- Reference RPM Specs: Maximum engine speed establishes 7250 rpm at peak power output Protocol.

Professional Workshop Service Manual & Technical Specifications

Essential Repair Service Manual: Piaggio X9 500 cc (2001-2003) Technical-Briefing

Specification-Class: Piaggio X9 500 cc (2001-2003) // Year-Coverage: Complete factory-authorized documentation // Specification-Class: Comprehensive 314-page technical reference.

| Document Overview | Primary Content | Reference Status |

|---|---|---|

| Engine & Transmission Systems | Automatic CVT transmission, trochoidal oil pump, fuel injection EMS integration | Complete specifications provided |

| Cooling & Lubrication | Centrifuge water pump, thermostat control, 4-bar pressure system | See Chapters 10-11 |

| Electrical & Diagnostics | Immobilizer decoder, fuel injection control unit, alternator charging circuits | Documented with diagnostic codes |

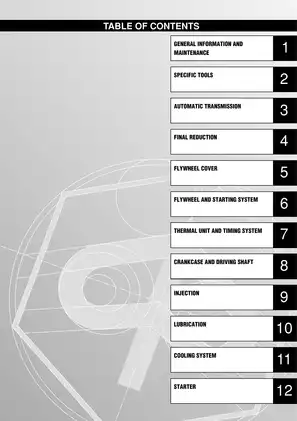

Rigorously requiring comprehensive technical documentation, the manual provides a structural breakdown of the Piaggio X9 500 cc power plant across 12 specialized chapters. Suspension service documentation covers front fork assemblies, rear shock absorbers, and steering bearing configurations. Disassembly instructions are documented for the automatic transmission, including drive pulley mechanics, clutch assembly procedures, and belt tension management systems.

Wear limits are specified for compression rings, piston clearances, and valve seat contact surfaces. System operation descriptions cover the integrated fuel injection and ignition management controlled by the EMS unit, with specialized attention to sensor inputs including coolant temperature, air intake temperature, and throttle position feedback. The documentation addresses crankcase separation, driving shaft alignment checks, and main bearing brass specifications with class-based coupling procedures.

Diagnostic procedures address troubleshooting for starting system anomalies, fuel supply pressure control, injector flow capacity verification, and spark advance timing optimization. Electrical fan control circuits, revolution counter commands, and immobilizer system programming are documented with LED signaling patterns. The manual documents torque specifications for the cylinder head fixing nuts to ensure proper combustion sealing and component integrity.

| Chapter Index | System Coverage | Documentation Level |

|---|---|---|

| General Information & Maintenance | Spark plug service, oil changes, coolant level management | Complete procedures |

| Fuel Injection & Control | EMS unit diagnostics, sensor calibration, trimmer value adjustment | Advanced service data |

| Cooling System | Thermostat temperature curves, fan activation thresholds, circuit bleeding | Full specifications |

| Braking System | Caliper service, brake fluid renewal, pressure divider valve operation | Complete service methods |

| Bodywork & Assemblies | Panel removal sequences, fastener locations, reassembly guidance | Procedural references |

Suspension service documentation covers handlebar repositioning, front fork seal ring replacement, and rear shock absorber support arm overhaul with specific focus on maintenance intervals and component wear evaluation. The layout provides reliable guidance for both routine maintenance operations and complete engine disassembly workflows, organized sequentially from simple spark plug checks through multi-step transmission and crankcase procedures.

Control system descriptions examine the stepper motor auxiliary air feed mechanism, pressure regulator calibration at 4 bar, and the immobilizer decoder interaction with the EMS control unit. Specific sections address the three-phase generator recharge circuit, voltage regulator output monitoring between 14.0-15.0V, and battery electrolyte density specifications. Working time tables reference standard service intervals measured in minutes, with operations ranging from 5-minute light bulb changes to 480-minute frame replacement procedures.

Safety prescriptions emphasize the use of genuine Piaggio components, proper tool selection including the comprehensive 50+ item specific tooling catalog, and hazardous material handling for battery electrolyte and brake fluid. The service station manual assumes technical familiarity with mechanical principles and provides cross-references to companion manuals for engine-specific procedures and bodywork assembly data.

FAQ

Customer Reviews

Read what our customers say about this Piaggio Maxi Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)