2005 Piaggio X9 Evolution 500 Workshop Manual

Factory repair documentation for the 500cc scooter engine — detailed service procedures, electrical schematics, fuel injection system, and transmission overhaul specifications. 443 pages of complete technical coverage.

Manual Preview

Sample pages from the 2005 Piaggio X9 Evolution 500 Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Piaggio X9 Evolution 500 (633234) — 2005 Comprehensive Technical Reference | X9 Evolution Series Repository.

- Maximum Displacement Data: 460 cm³ (28 cu in) is standardized to the single-cylinder four-stroke engine architecture Specifications.

- Authorized Power Output: For optimal performance, 29.5 kW at 7500 rpm dictates the maximum net flywheel horsepower Framework.

- Established Torque Specification: 43 Nm at 5500 rpm — represents the peak crankshaft rotational force Standards.

- Measured Cooling Capacity: The liquid cooling circuit requires approximately 1.8 L for thermal regulation Protocol.

- Rated Fuel Tank Volume: Reaches 14.5 L (3.8 US gal) including reserve margin Parameters.

- Critical Battery Rating: The electrical system is specified at 12V–14Ah for starter motor activation Margin.

Professional Workshop Service Manual & Technical Specifications

Unified Field Manual: Maxi Scooter Piaggio X9 Evolution 500 Workshop Manual (2005) - Comprehensive Guide to Maintenance and Repairs Troubleshooting-Index

Maintenance-Category: X9 Evolution 500 (2005) // Machine-Range: Service procedures / Hydraulic and fuel system logic // Maintenance-Category: Complete technical reference with torque specifications and component diagrams.

| Technical System | Documentation Coverage | Reference Details |

|---|---|---|

| Engine Architecture | Complete specifications documented | Four-stroke, 460cc displacement with timing chain system |

| Transmission Assembly | Comprehensive component guide | Automatic expandable pulley variator with torque limiter |

| Brake Hydraulics | Full circuit documentation | Dual-circuit combined and independent brake systems |

Diagnostic procedures address the engine's single-cylinder architecture, fuel injection parameters, and electrical system integration, combining ignition management with coolant circulation controls and comprehensive wiring schematics. Service sections detail the transmission cover removal sequence, driven pulley bearing replacement procedures, and clutch assembly protocols, which incorporate multiple specialized fixture points and bearing classification categories. Technical specifications are provided for the crankshaft alignment methodology, connecting rod clearance limits, and piston ring gap measurements, alongside factory specifications for the compression ratio shimming system that maintains the 10.5:1 calibration. Engine rebuild procedures are documented for the cylinder-head gasket selection process, valve clearance reference data, and timing system phase alignment using wheel speed sensor references.

Systematic Standard

Removal procedures are documented for the flywheel cover and stator assembly, including the oil pump circulation pathways and by-pass valve seating geometry. The manual documents torque specifications for the engine block coupling screws to ensure proper fastening sequence and structural integrity. Parts identification is covered for the fuel system components, including the pump bracket, pressure regulator, and injector support configuration, with quick-coupling terminal specifications and fuel pressure regulation parameters. The document provides reference specifications for the immobilizer decoder circuit, diagnostic connector pin assignments, and self-diagnosis fault storage procedures.

Systematic Architecture

Removal procedures are documented for the front suspension fork stem sealing ring replacement and hydraulic shock absorber servicing, including the preload adjustment mechanism. Technical specifications are provided for the steering column bearing replacement, tapered bearing seat dimensions, and fork stanchion oil capacity requirements. Factory specifications are documented for the brake caliper piston diameter classification, disc runout tolerance limits, and brake fluid DOT 4 compatibility standards.

Modular Logic-Path

The document includes the cooling system thermostat opening temperature threshold, electric fan activation parameters, and expansion tank pressure cap calibration value. Parts identification is covered for the electrical system components including the magneto flywheel configuration, hall-effect sensor positioning, and rpm-timing sensor reluctance gap specifications. Engine rebuild procedures are documented for the crankcase half-coupling gasket positioning and main bearing installation sequence using thermal expansion techniques.

Core Interface

Removal procedures are documented for the intake manifold butterfly valve assembly and throttle body position sensor configuration. Technical specifications are provided for the transmission end gear bearing replacement using specialized extraction tooling and heat-gun application protocols. Factory specifications are documented for the drivetrain countershaft lock wrench positioning and gear meshing verification using timing pin alignment methods.

Technical Interface

The manual documents torque specifications for the rear hub cover coupling screws to ensure proper oil circulation and bearing support contact, which maintains optimized lubrication pressure within the final drive assembly. Parts identification is covered for the suspension system components including the swing-arm bearing socket geometry, elastic coupling characteristics, and oscillating arm pivot axis alignment procedures.

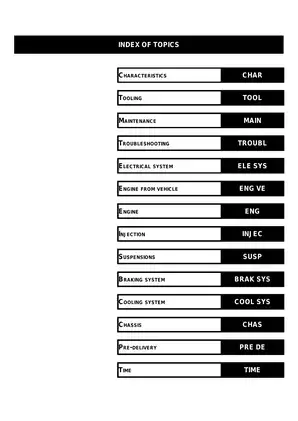

Sources and Documentation: The manual contains 443 pages of technical content addressing characteristic specifications, tooling requirements, maintenance schedules, troubleshooting procedures, electrical system architecture, engine overhaul methodologies, injection system diagnostics, suspension service operations, and braking system maintenance protocols with complete component identification and assembly clearance reference data.

FAQ

Customer Reviews

Read what our customers say about this Piaggio Maxi Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)