Teledyne Continental C75, C85, C90 & O-200 Engine Overhaul Manual 1976-Present

Complete overhaul manual for Teledyne Continental C75, C85, C90 & O-200 engines. Details engine systems, components, and procedures for maintenance and repair. PN C4077-90960

Manual Preview

Sample pages from the Teledyne Continental C75, C85, C90 & O-200 Engine Overhaul Manual 1976-Present manual

Purchase & Download

Models Covered & Key Technical Specifications

Teledyne Continental C75, C85, C90 & O-200 (C4077-90960) - 1976-Present Official Teledyne Continental Engine Overhaul Manual | Aircraft Engine Binder.

- Authorized: For C75/C85/C90, 4 cylinders establish the standard cooling system operation.

- Critical: O-200 models feature a 4-1/16 inch cylinder bore for enhanced performance.

- Operational: C90 and 0-200 engines have a 3-7/8 inch piston stroke, leading to higher compression ratios.

- Established: The manual covers variations in equipment denoted by suffix dash numbers, which adapt basic engines to aircraft.

- Measured: Carburetor calibration in C90 models differs from C75 and C85 models.

- Maximum: Cylinder heads are identified as aluminum alloy castings with externally finned steel barrels.

Professional Workshop Service Manual & Technical Specifications

Structured Training Diagnostic Manual: Aircraft Continental C75, C85, C90 & O-200 1976–Present - Comprehensive Aircraft Engine Overhaul Manual Manual-Nexus

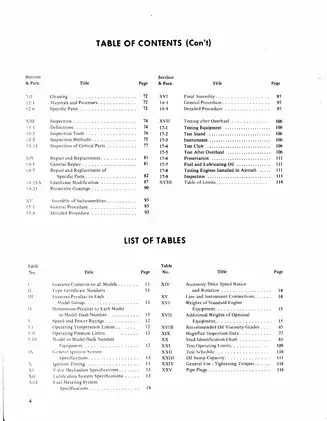

| Reference-Category: C75, C85, C90, O-200 // Design-Core: Engine / Aircraft Logic // Reference-Category: Overhaul Procedures. TABLE OF CONTENTS (Con't) | Section & Para. | Title | Page |

|---|---|---|---|

| 1-1 | Model Designation | 9 | |

| 1-2 | Definitions and Abbreviations | 9 | |

| 3-1 | Difference Between Model Groups | 16 | |

| 3-2 | Significance of C Series Dash Numbers and Letters | 16 | |

| 3-3 | Model Conversions | 16 | |

| 3-4 | Optional Equipment | 17 | |

| 3-5 | Superseding Parts | 17 | |

| 3-6 | Crankcase Construction | 17 | |

| 3-7 | Crankshafts | 18 | |

| 3-8 | Nitrided Crankshafts | 18 | |

| 3-9 | Crankshaft Gears | 19 | |

| 3-10 | Connecting Rods | 19 | |

| 3-11 | Camshafts | 19 | |

| 3-12 | Camshaft Gears | 20 | |

| 3-13 | Hydraulic Valve Lifters | 20 | |

| 3-14 | Construction | 20 | |

| 3-15 | Types | 21 | |

| 3-16 | Operation | 21 | |

| 3-17 | Pushrods and Housings | 21 | |

| 3-18 | Piston Assemblies | 21 | |

| 3-19 | Cylinder Assemblies | 21 | |

| 3-20 | Cylinder and Head | 21 | |

| 3-21 | Valves | 21 | |

| 3-22 | Valve Springs | 21 | |

| 3-23 | Rocker Arms and Shaft | 22 | |

| 3-24 | Types | 22 | |

| 3-25 | Crankcase Cover Assembly for -12, -14, -16 and 0-200 Models | 22 | |

| 3-26 | Crankcase Cover Assembly for -8 Models | 23 | |

| 3-27 | Gear Train | 23 | |

| 3-28 | Carburetor Induction System | 24 | |

| 3-29 | Oil Sumps | 24 | |

| 3-30 | Ignition System | 24 | |

| 3-31 | Unshielded | 24 | |

| 3-32 | Radio Shielded Ignition Systems | 25 | |

| 3-33 | Switch Wire Terminals | 25 | |

| 3-34 | Magneto Drive Gears | 25 | |

| 3-35 | Impulse Coupling Operation | 26 | |

| 3-36 | Delco-Remy Starter | 26 | |

| 3-37 | Prestolite Starter | 26 | |

| 3-38 | Generator/Alternator and Drive | 26 | |

| 3-39 | Side Mounted Fuel Pump | 26 | |

| 3-40 | Dual Fuel Pump Equipment | 26 | |

| 3-41 | Lubrication System | 27 | |

| 3-42 | Oil Circulation in -8 Models | 27 | |

| 3-43 | Oil Circulation in -12, -14, -16 and 0-200 Models | 27 | |

| 3-44 | Oil Cooler Equipment | 27 | |

| SECTION IV UNPACKING THE ENGINE | 29 | ||

| 4-1 | Shipping Crates | 29 | |

| 4-2 | Method of Packing and Preservation | 29 | |

| 4-3 | Removal of Engine from Crate | 30 | |

| 4-4 | Preparation for Installation | 30 | |

| SECTION V STORAGE OF ENGINES | 31 | ||

| 5-1 | General | 31 | |

| 5-2 | Flyable Storage (7 to 30 days) | 31 | |

| 5-3 | Temporary Storage (Up to 90 days) | 31 | |

| 5-4 | Indefinite Storage | 32 | |

| 5-5 | Procedures Necessary for Returning an Aircraft to Service are as Follows | 33 | |

| 5-6 | Aircraft Stored in Accordance with the Indefinite Storage Procedures Should be Inspected per the Following Instructions | 33 | |

| SECTION VI INSTALLATION IN AIRPLANE AND REMOVAL | 34 | ||

| 6-1 | Mounting the Engine | 34 | |

| 6-2 | Fuel Systems | 38 | |

| 6-3 | Oil System | 38 | |

| 6-4 | Propeller Installation | 38 | |

| 6-5 | Engine Removal | 39 | |

| SECTION VII OPERATING INSTRUCTIONS | 40 | ||

| 7-1 | Procedure Preliminary to Starting | 40 | |

| 7-2 | Starting Procedure | 40 | |

| 7-3 | Warm-Up | 40 | |

| 7-4 | Ground Test | 41 | |

| 7-5 | Take-Off | 41 | |

| 7-6 | Climbing | 41 | |

| 7-7 | Level Flight | 41 | |

| 7-8 | Let-Down and Landing | 42 | |

| 7-9 | Stopping the Engine | 42 | |

| 7-10 | Lubricating Oil | 42 | |

| 7-11 | Viscosity | 42 | |

| 7-12 | Oil Change Periods | 43 | |

| 7-13 | Oil Change Procedure | 43 | |

| 7-14 | Engine Fuel | 43 | |

| SECTION VIII ENGINE TROUBLES AND SERVICE REPAIR | 44 | ||

| SECTION IX PERIODIC INSPECTION AND MAINTENANCE | 48 | ||

| 9-1 | Daily Inspection | 48 | |

| 9-2 | First Fifty Hour Inspection | 48 | |

| 9-3 | 100-Hour Periodic Inspection | 49 | |

| SECTION X ADJUSTMENT AND MINOR REPAIR | 51 | ||

| 10-1 | Carburetors | 51 | |

| 10-2 | Removal | 51 | |

| 10-3 | Installation | 51 | |

| 10-4 | Stromberg Carburetor Adjustment | 51 | |

| 10-5 | Marvel-Schebler Carburetor Adjustment | 52 | |

| 10-6 | Maintenance | 52 | |

| 10-7 | Magnetos | 53 | |

| 10-8 | Removal | 53 | |

| 10-9 | Installation and Timing | 53 | |

| 10-10 | 54 | ||

| 10-11 | 54 | ||

| 10-12 | 54 | ||

| 10-13 | Connections | 55 | |

| 10-14 | Maintenance of Eisemann AM-4 Magnetos | 56 | |

| 10-15 | Maintenance of Eisemann LA-4 Magnetos | 56 | |

| 10-16 | Maintenance of Bendix S4RN-21 and S4-LN-21 Magnetos | 56 | |

| 10-17 | Slick Magnetos | 57 | |

| 10-18 | Replacement of Ignition Cables | 57 | |

| 10-19 | Unshielded Cables | 57 | |

| 10-20 | Shielded Ignition Cables | 58 | |

| 10-21 | 58 | ||

| 10-22 | 58 | ||

| 10-23 | 58 | ||

| 10-24 | Delco-Remy Starter | 59 | |

| 10-25 | Removal | 59 | |

| 10-26 | Installation | 59 | |

| 10-27 | Adjustment | 60 | |

| 10-28 | Maintenance | 60 | |

| 10-29 | Performance Data | 60 | |

| 10-30 | Prestolite Starter | 60 | |

| 10-31 | Removal | 60 | |

| 10-32 | Installation | 60 | |

| 10-33 | Adjustment | 60 | |

| 10-34 | Maintenance | 60 | |

| 10-35 | Performance Data | 60 | |

| 10-36 | Prestolite Starter Clutch Overhaul | 60 | |

| SECTION XI DISASSEMBLY | 67 | ||

| 11-1 | Preliminary Operations | 67 | |

| 11-2 | Fixtures | 67 | |

| 11-3 | Starter and Generator | 67 | |

| 11-4 | Preliminary Cleaning | 67 | |

| 11-5 | Ignition System | 67 | |

| 11-6 | Locking Parts | 68 | |

| 11-7 | Fuel Pumps | 68 | |

| 11-8 | Carburetor and Air Intake Housing | 68 | |

| 11-9 | Air Scoop | 68 | |

| 11-10 | Disassembly | 68 | |

| 11-11 | Non-Reusable Parts | 68 | |

| 11-12 | Oil Sump and Suction Tube | 68 | |

| 11-13 | Air Induction System | 68 | |

| 11-14 | Rocker Covers | 68 | |

| 11-15 | Cylinders | 69 | |

| 11-16 | Piston Assemblies | 69 | |

| 11-17 | Protectors | 69 | |

| 11-18 | Crankcase and Cover | 69 | |

| 11-19 | Connecting Rods | 70 | |

| 11-20 | Crankcase | 70 | |

| 11-21 | Crankcase Cover | 70 | |

| 11-22 | Cylinders | 71 | |

| SECTION XII CLEANING PARTS | 72 | ||

| 12-1 | Materials and Processes | 72 | |

| 12-2 | 72 | ||

| 12-3 | 72 | ||

| 12-4 | 72 | ||

| 12-5 | 72 | ||

| 12-6 | Specific Parts | 72 | |

| 12-7 | Cylinders | 72 | |

| 12-8 | Pistons | 72 | |

| 12-9 | Valves | 73 | |

| 12-10 | Rocker Shafts | 73 | |

| 11-11 | Pushrods, Valve Rockers and Other Small Steel Parts | 73 | |

| 12-12 | Camshaft and Crankshaft | 73 | |

| 12-13 | Connecting Rods | 73 | |

| 12-14 | Crankcase | 73 | |

| 12-15 | Gears | 73 | |

| 12-16 | Sheet Metal Parts | 73 | |

| SECTION XIII INSPECTION | 74 | ||

| 13-1 | Definitions | 74 | |

| 13-2 | Inspection Tools | 74 | |

| 13-3 | Gauges | 74 | |

| 13-4 | Fixtures | 75 | |

| 13-5 | Inspection Methods | 75 | |

| 13-6 | Visual Inspection | 75 | |

| 13-7 | Etching | 75 | |

| 13-8 | Dimensional Inspection | 75 | |

| 13-9 | Magnaflux Inspection | 76 | |

| 13-10 | 76 | ||

| 11-11 | 76 | ||

| 13-12 | 76 | ||

| 13-13 | Fluorescent Particle Inspection | 77 | |

| 13-14 | Inspection of Critical Parts | 77 | |

| 13-15 | Crankcase | 77 | |

| 13-16 | Crankshaft | 78 | |

| 13-17 | Connecting Rods | 78 | |

| 13-18 | Piston Pins | 78 | |

| 13-19 | Pistons | 78 | |

| 13-20 | Pushrods | 78 | |

| 13-21 | Rocker Arms | 78 | |

| 13-22 | Valves | 79 | |

| 13-23 | Valve Springs | 79 | |

| 13-24 | Camshafts | 79 | |

| 13-25 | Cylinders | 79 | |

| 13-26 | Hydraulic Valve Lifters | 79 | |

| 13-27 | Gears | 79 | |

| SECTION XIV REPAIR AND REPLACEMENT | 81 | ||

| 14-1 | General Repair | 81 | |

| 14-2 | Castings | 81 | |

| 14-3 | Stud Replacement | 81 | |

| 14-4 | Helical Coil Insert Installation | 81 | |

| 14-5 | 82 | ||

| 14-7 | Repair and Replacement of Specific Parts | 82 | |

| 14-8 | Cylinder and Head Assembly | 82 | |

| 14-9 | Crankshaft | 85 | |

| 14-10 | Connecting Rods | 86 | |

| 14-11 | Pistons, Rings and Pins | 86 | |

| 14-12 | 86 | ||

| 14-13 | Crankcase and Cover Assembly | 87 | |

| 14-13A | Starter Clutch and Crank Shaft Modification | 87 | |

| 14-14 | Camshaft | 90 | |

| 14-15 | Hydraulic Valve Lifters | 90 | |

| 14-16 | Oil Sump | 90 | |

| 14-17 | Intake Tubes | 90 | |

| 14-18 | Gears | 90 | |

| 14-19 | Air Scoops and Intake Housings | 90 | |

| 14-20 | Vacuum Pump Adapter | 90 | |

| 14-21 | Protective Coatings | 90 | |

| 14-22 | 91 | ||

| 14-23 | Refinishing Enameled Parts | 91 | |

| 14-24 | "Alodizing" and Repair of "Alodized" Surfaces | 91 | |

| 14-25 | Application of "Alodine 1200" | 91 | |

| 14-26 | Repair of Alodized Surfaces | 91 | |

| 14-27 | Ignition Cables | 92 | |

| 14-28 | Delco-Remy Starter | 92 | |

| 14-29 | Prestolite Starter | 92 | |

| 14-30 | Delco-Remy Generator | 92 | |

| 14-31 | Stromberg NA-S3A1 Carburetor | 92 | |

| 14-32 | Marvel-Schebler MA-3SPA Carburetor | 92 | |

| 14-33 | Magnetos | 92 | |

| SECTION XV ASSEMBLY OF SUBASSEMBLIES | 93 | ||

| 15-1 | General Procedure | 93 | |

| 15-2 | Cleaning and Lubrication | 93 | |

| 15-3 | New Parts Required | 93 | |

| 15-4 | Detailed Procedure | 93 | |

| 15-5 | Crankcase Cover Assembly | 93 | |

| 15-6 | Crankcase | 94 | |

| 15-7 | Crankshaft and Connecting Rods | 94 | |

| 15-8 | 95 | ||

| 15-9 | Intake Pipe and Hose Connectors | 95 | |

| 15-10 | Intake Air Filter | 95 | |

| 15-11 | Oil Sump and Suction Tube | 95 | |

| 15-12 | Magnetos | 95 | |

| 15-13 | Cylinders | 95 | |

| 15-14 | Pistons | 96 | |

| 15-15 | Pushrods | 96 | |

| 15-16 | Vacuum Pump Adapter | 96 | |

| SECTION XVI FINAL ASSEMBLY | 97 | ||

| 16-1 | General Procedure | 97 | |

| 16-2 | Assembly Stand | 97 | |

| 16-3 | New Parts Required | 97 | |

| 16-4 | Detailed Procedure | 97 | |

| 16-5 | Crankcase and Enclosed Parts | 97 | |

| SECTION XVII TESTING AFTER OVERHAUL | 106 | ||

| 17-1 | Testing Equipment | 106 | |

| 17-2 | Test Stand | 106 | |

| 17-3 | Instruments | 106 | |

| 17-4 | Test Club | 106 | |

| 17-5 | Engine Test After Overhaul | 107 | |

| 17-6 | Preservation | 107 | |

| 17-7 | Fuel and Lubricating Oil | 107 | |

| 17-8 | Testing Engines Installed in Aircraft | 111 | |

| 17-9 | Inspection | 111 |

Safely requiring 1200 RPM establishes the operational parameters for engine diagnostics. Technical notes are provided for 4-stroke Otto cycle engines to ensure proper operation. Quality checks are addressed for cylinder head temperatures and oil pressure readings. The [component] section documents fuel systems and oil circulation. The troubleshooting chapter addresses common engine problems and their remedies. Torque Statement: Documents torque specifications for engine mounting bolts to ensure proper vibration dampening. The service manual covers engine components, maintenance procedures, troubleshooting, and testing.

FAQ

Customer Reviews

Read what our customers say about this Continental Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)