Teledyne Continental TSIO-360-F / FB Aircraft Engine 1978 Operation and Maintenance Manual

For turbocharged Continental TSIO-360-F and TSIO-360-FB engines: starting procedures, cruise control charts, turbocharger operation, and complete troubleshooting guide. FAA Form X-30512.

Manual Preview

Sample pages from the Teledyne Continental TSIO-360-F / FB Aircraft Engine 1978 Operation and Maintenance Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Teledyne Continental TSIO-360-F & FB — 1978 Industrial Applied Vault | TSIO-360 Series Module.

- Established Fluid Levels: The oil sump capacity of 25 quarts is rated at maximum engine lubrication Margin.

- Operational Adjustment Range: For optimal performance, 41.0 inches of mercury establishes the maximum manifold pressure Protocol.

- Certified Energy Draw: 200 hp at 2575 rpm — supports the rated continuous horsepower Architecture.

- Factory Burn-in Temperature: The compression ratio requires 8.5:1 for standard combustion chamber pressure Norms.

- Approved Enclosure Specs: At critical altitude of 12,000 feet, the engine achieves 100% rated power output Bounds.

- Measured Storage Capacity: Cylinder displacement reaches 360 cubic inches for the opposed-piston engine Topology.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Field Manual: Aircraft Operator's Manual: Continental TSIO-360-F & TSIO-360-FB 1978 - Essential Aircraft Engine Powertrain-Manual

Diagnostic-Area: Teledyne Continental Motors TSIO-360-F, TSIO-360-FB // Machine-Range: Turbocharged aircraft engine operation / Fuel injection system Logic // System-Identifier: Opposed cylinder, fuel-injected turbocharger configuration.

| Specification | Documentation Scope | Reference |

|---|---|---|

| Operating specifications and power ratings | Complete coverage of continuous rated power, manifold pressure, critical altitude data | Section I |

| Fuel system architecture | Multi-nozzle continuous-flow injection system with metering controls | Section IV, Figure 7 |

| Turbocharger operation and failure procedures | Wastegate assembly, compressor function, surge management guidance | Section III, VI |

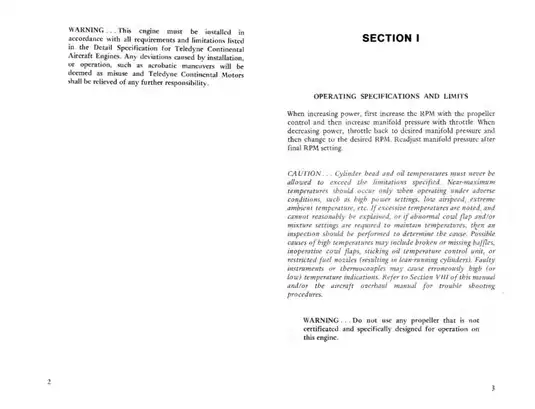

Technical content addresses operating specifications and limits, normal operating procedures covering preflight through landing sequences, in-flight emergency procedures including engine roughness assessment and turbocharger malfunction remedies, and engine performance data with cruise control methodology via power charts. The document also includes abnormal environmental conditions guidance for cold weather preheating, hot weather operation at high-altitude airports, and ground operations protocol.

Technical Framework

Verification procedures are included for ignition system checks including magneto differential RPM drop limits and spark plug terminal continuity. The manual provides comprehensive documentation of the fuel injection system, which employs a continuous-flow design with air-bleed nozzles spraying fuel directly into cylinder intake ports. Repair information is provided for troubleshooting rough engine operation at idle and elevated speeds, including mixture adjustment protocols and fuel flow verification against specified pressure values.

Precise Parameters

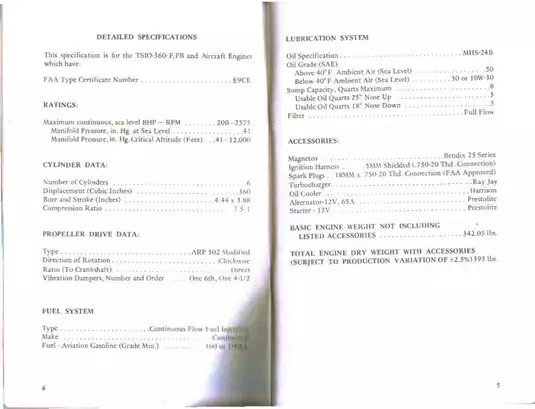

The document includes coverage of cylinder head and oil temperature monitoring, manifold pressure control during takeoff and climb phases, and fuel flow management using EGT (exhaust gas temperature) reference data. Brake horsepower performance curves show altitude compensation factors and sea-level performance characteristics. The lubrication system specifications include approved aviation oils meeting TCM specification MHS-248 and filter replacement intervals.

Structured Framework

Engine description sections document the opposed-cylinder configuration with horizontally-arranged cylinder assemblies, oil system architecture including full-flow filtration and pressure relief operation, and induction system components from air filter through turbocharger compressor to cylinder intake ports. The ignition system encompasses dual magnetos with impulse coupling, firing order designation (1-6-3-2-5-4), and distributed secondary cable architecture.

Strategic Topology

Inspection protocols are documented across daily preflight checks, 50-hour, and 100-hour service intervals. Servicing requirements include oil analysis, spark plug gap verification (0.015-0.019 inch specification), fuel nozzle inspection for leakage, and turbocharger bearing lubrication confirmation through external supply line examination. The manual documents torque specifications for various fastener applications to ensure proper assembly integrity.

Systematic Protocol

Storage procedures are detailed for both temporary (up to 30 days) and flyable storage (7-30 days) conditions, including preservation oil application through spark plug ports and sealed engine opening protocols. Troubleshooting charts cross-reference probable causes with corrective actions for conditions including starting failure, rough idle operation, poor acceleration, power loss at altitude, fluctuating fuel pressure, and oil pressure irregularities. The glossary provides technical terminology definitions covering manifold pressure concepts, altitude rating conventions, fuel octane specifications, and turbocharger operational characteristics.

The manual documents torque specifications for engine assembly components to ensure proper fastener clamping force and seal compression uniformity.

FAQ

Customer Reviews

Read what our customers say about this Continental Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)