1950-1982 Piper PA-18 Super Cub Parts Catalog

Find OEM Piper PA-18 and PA-18A replacement parts by section: wing, fuselage, electrical, engine, control systems. Complete part numbers and serial number applicability included.

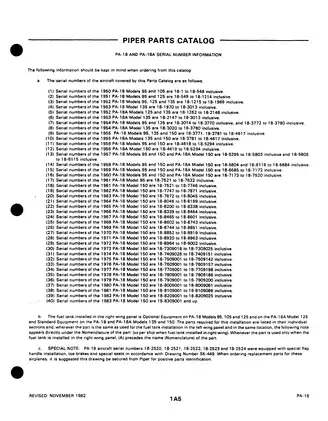

Manual Preview

Sample pages from the 1950-1982 Piper PA-18 Super Cub Parts Catalog manual

Purchase & Download

Models Covered & Key Technical Specifications

Piper PA-18, PA-18A Super Cub — 1950–1982

Operational Mechanical Handbook | PA-18 Series Packet.

- Documented Displacement Data: 1590 cc (97 cu in) to 2850 cc (174 cu in) engine options are specified as the standard aircraft cylinder volume Requirements.

- Calibrated Horsepower Charge Quantity: For operational performance, 90 HP (Continental C-90) to 150 HP (Lycoming O-320) is measured at rated power output Threshold.

- Authorized Wing Area Configuration: The airframe controls 150 sq ft (13.9 sq m) of total wing surface area for lift and stability Mapping.

- Core Empty Weight Mass Specs: Standard aircraft require 575–701 lbs (261–318 kg) empty weight range depending on engine type Configuration.

- Rated Maximum Gross Weight Twist Specifications: The loaded airframe governs 1220–1350 lbs (553–612 kg) maximum takeoff weight Benchmarks.

- Principal Fuel Capacity Range: Tank volume reaches 36–37 US gallons (136–140 L) total capacity across single and dual tank configurations Range.

Professional Workshop Service Manual & Technical Specifications

Verified Service Technical Manual: Aircraft Piper PA-18, PA-18A, PA-18 Super Cub 1950-1982 - Comprehensive Parts Catalog and Maintenance Guide Procedure-Database

Machine-Range: Piper PA-18, PA-18A Super Cub aircraft 1950-1982 // Engine-Type: Continental C-90, Lycoming O-235, O-290, O-320 systems // Machine-Range: Complete propeller, avionics, and optional equipment specifications.

| Integrated-Framework | Technical-Path | Framework |

|---|---|---|

| Wing and Fuel System assemblies | Documented across Sections I-II | Complete parts identification |

| Fuselage, Controls, and Tail Groups | Reference specifications provided | Serial number cross-reference |

| Power Plant and Electrical Systems | Maintenance documentation included | Chapter grid locations noted |

Documentation sections include Section I addressing wing group assemblies and fuel tank installations, Section II covering fuselage components and instrument panels, Section III containing agricultural equipment systems, Section IV detailing tail surface installations, and Section V describing chassis and landing gear components, followed by power plant documentation in Section VI, fuel system layouts in Section VII, electrical system configurations in Section VIII, control system references in Section IX, radio installation guides in Section X, and miscellaneous equipment options in Section XI.

Diagnostic Topology

Systematically requiring identification of component location and function, this catalog presents parts organized by major assembly groups with figure references and grid coordinates. The document includes exploded-view drawings that reference part numbers across individual assemblies, facilitating logical navigation between related components. Logical framework enables rapid location of specific parts through hierarchical illustration arrangement, where each figure number corresponds to a discrete assembly section with indexed nomenclature listings. The reference structure supports cross-identification by aircraft serial number, which determines applicability and availability of particular replacement parts across different production years and engine configurations.

Integrated Benchmarks

Reference data is included for all primary aircraft systems spanning wing structures, control surfaces, powerplant installations, and electrical equipment. The catalog documents complete assemblies including fabric-covered and metal components, control cable systems, instrument panel configurations for standard and advanced gyro installations, and specialized agricultural equipment packages. Each major assembly section provides detailed parts listings with nomenclature descriptions, part numbers for commercial hardware items, and serial number ranges indicating applicability across the 33-year production span. The document addresses both standard and optional equipment configurations, distinguishing between items used on base models versus specialized agricultural variants and restricted-category aircraft.

Core Framework

Alignment specifications are included for wing panel assemblies, flap installations, and control surface adjustments across multiple model variants. Systematic organization by grid reference enables location of documentation for fuel system installations, landing gear configurations including wheelbases and brake assemblies, and tail wheel options ranging from Scott 6-inch to Maule 8-inch specifications. The manual documents torque specifications for structural fasteners to ensure proper assembly integrity across wing strut attachments, engine mounting systems, and landing gear components. Wiring diagrams are provided for electrical system installations covering generator and alternator configurations, battery connections, navigation and landing light circuits, and various radio installation frameworks accommodating G.E., Bendix, Lear, Narco, and Piper PTR-1 equipment.

Integrated Benchmarks

Diagnostic procedures are covered for identifying aircraft serial number applicability to specific parts, determining fuel tank configurations affecting right-wing installation kits, and selecting correct component variations across production batches. The catalog references special notes regarding aircraft equipped with custom flap handles, toe brakes, and specialized seating per Drawing Number SK-449, along with documentation for metal belly panel installations and sealed battery box conversions. Reference material includes paint color specifications documenting dope and enamel selections across production years, from 1950 nitrate dope formulations through 1958-and-later butyrate options in colors including Lock Haven Yellow, Miami Blue, and Sacramento Green variants.

Modular Sequences

The document encompasses optional equipment kits addressing auxiliary fuel tanks, cold air vent installations, cargo compartment configurations, and specialized agricultural systems for spraying and dusting operations. Conversion kits are referenced for transforming duster installations to sprayer configurations and vice versa, with model-specific mounting requirements for Oberdorfer gear pumps, 3/4-inch centrifugal, and 1-inch centrifugal pump assemblies. Documentation includes references to seaplane conversion components, float installation kits for EDO Model 89-2000 units, and emergency dump system assemblies for hopper-equipped variants, all cross-indexed by aircraft serial number and applicable model designation.

FAQ

Customer Reviews

Read what our customers say about this Piper Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)