2005 Piaggio Beverly 250 USA Workshop Manual

Manual Preview

Sample pages from the 2005 Piaggio Beverly 250 USA Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

-

Piaggio Beverly 250 USA (633574) — 2005 Vault Identifier - Beverly 250 USA / Beverly 250 USA Quasar Library (Official Repository).

-

Advanced Timing: 10°±1 at 2000 rpm establishes the ignition baseline for the 244.29 cm³ engine.

-

Core Capacity: 1200 cc signifies the total lubricant volume required for standard engine oil service.

-

Technical Gap: 0.7–0.8 mm defines the precise electrode distance for the Champion RG 4 HC spark plug.

-

Specific Pressure: 2.1 bar is required for the front tubeless 110/70-16" tire at ambient temperature.

-

Essential Clearance: 0.10 mm must be maintained for cold intake valve adjustment to ensure cylinder integrity.

Professional Workshop Service Manual & Technical Specifications

Integrated Technical Manual Reference: Piaggio Beverly 250 USA 633574

Piaggio Beverly 250 USA (633574) — 2005

Resource-Library

Diagnostic Parameters

Governing operational sequences for the Quasar engine architecture requires adherence to the comprehensive framework established by Piaggio & C. Spa. Within the component context, the workshop documentation serves as a static technical anchor for trained service mechanics possessing fundamental knowledge of mechanical principles. To ensure system alignment, the provided descriptions and illustrations represent a non-binding reference that the manufacturer reserves the right to modify for product improvement or manufacturing necessity. Sustaining environmental safeguards and personal safety during technical oversight depends on the strict observation of the specific protocols detailed in the original documentation.

Systematic Interface

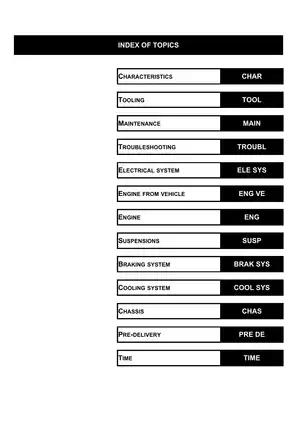

| System Grouping | Component Categories | Document Scope Areas |

|---|---|---|

| Propulsion Core | Engine Assembly, Cooling System, Fuel Supply | Internal Lubrication and Timing Logic |

| Chassis Framework | Frame, Suspensions, Steering | Wheel and Tire Integrity |

| Electrical Topology | Ignition Circuit, Charging System, Lighting | Wiring and Fuse Distribution |

| Control Interface | Braking System, Transmission, Instrumentation | Service Maintenance Intervals |

Modular Architecture

Rigorously validating system logic for the secondary air system and anti-evaporation assembly involves monitoring the specified vacuum connections and flow paths defined by the OEM. To facilitate appropriate system maintenance, all lubricants and spare parts utilized must conform to the manufacturer-defined specifications listed in the recommended products sections. Procedural execution regarding the ignition timing or valve clearance necessitates the use of the specialized equipment and stores codes designated for this specific vehicle profile. Establishing operational thresholds for the braking and cooling systems follows the rigorous diagnostic benchmarks set forth in the factory workshop guide.

FAQ

Customer Reviews

Read what our customers say about this Piaggio Maxi Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)