2003 GAS GAS Supermoto EC 125 / 200 / 250 / 300 Service Manual

EC series enduro competition motorcycles technical service documentation with maintenance schedules, ignition timing CDI adjustment, and carburetor tuning specifications

Manual Preview

Sample pages from the 2003 GAS GAS Supermoto EC 125 / 200 / 250 / 300 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

GAS GAS Supermoto EC 125, EC 200, EC 250, EC 300 — 2003 Precision Engineering Repository | Supermoto Series Packet.

- Factory Assembly Gap: For optimal ignition performance, 1 mm APMS defines the ignition timing specification Mapping.

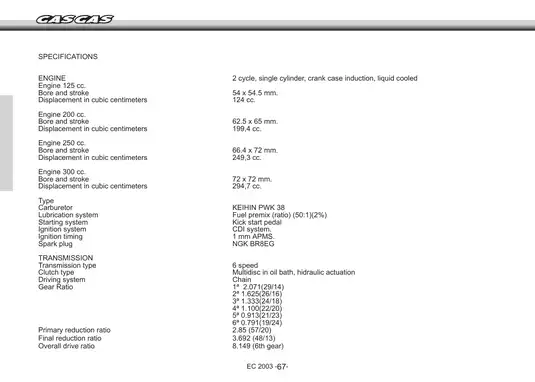

- Calibrated Displacement Data: The engine displacement achieves 124 cc (125 cc), 199.4 cc (200 cc), 249.3 cc (250 cc), and 294.7 cc (300 cc) respectively Configuration.

- Key Load Capacity: Rear axle nut — determines the wheel retention force at 98 N·m (70 ft-lbs) Benchmarks.

- Primary Thermal Envelope: The cooling system requires 1.1 L total coolant capacity for aluminum engine protection Range.

- General Size Parameters: Fuel tank capacity sets the operational range at 9.5 L (2.5 US gallons) Sequences.

- Integral Running Clearance: Drive chain slack reaches 30–50 mm (1.2–2.0 in) between the chain and swing arm Baseline.

Professional Workshop Service Manual & Technical Specifications

Practical Workshop Manual: Motorcycle GASGAS Supermoto EC 125, EC 200, EC 250, EC 300 - Comprehensive Service & Repair Manual, 2003 edition Reference-Archive

Engine-Type: GAS GAS EC 125 (2003), GAS GAS EC 200 (2003), GAS GAS EC 250 (2003), GAS GAS EC 300 (2003) // Series-Validation: Two-stroke Competition Enduro / Multi-displacement Powertrain Logic // Technical-Scope: Liquid-cooled CDI ignition, 6-speed transmission, WP/Marzocchi/Öhlins suspension systems.

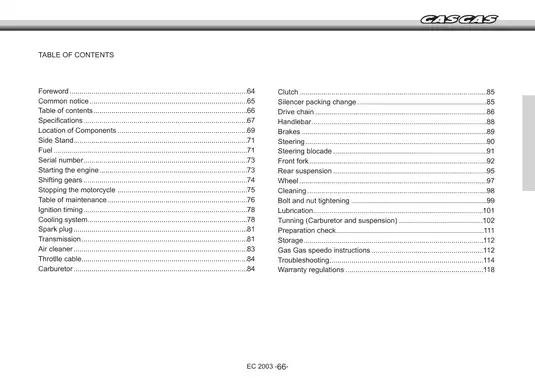

| Documentation Element | Scope | Reference |

|---|---|---|

| Engine Specifications | Bore/stroke dimensions, displacement volumes for all models | Pages 67-68 |

| Transmission Systems | Gear ratios, clutch type, chain drive configuration | Pages 67-68 |

| Chassis Architecture | Suspension stroke, brake disc sizing, fuel capacity | Pages 68-69 |

Accurately requiring systematic maintenance protocols, the manual encompasses engine systems, transmission operation, and chassis management. The document addresses fuel mixing ratios for 2-stroke lubrication, cooling system maintenance including radiator care and antifreeze specifications, and spark plug evaluation procedures. Carburetor tuning is thoroughly documented with standard settings, correction factors for altitude and temperature conditions, and jet needle positioning guidance. Ignition timing references are provided for CDI system verification, and transmission oil specifications including capacity and change intervals are detailed.

Service intervals are documented for clutch friction plate inspection, drive chain slack adjustment, and brake disc wear assessment. The manual covers front fork oil level management for WP, Marzocchi, and Öhlins suspension variants, with rebound and compression dampening adjustment click ranges. Rear suspension spring preload adjustment procedures and shock absorber oil viscosity recommendations are included. Component locations are identified for fuel tank fill cap, air cleaner assembly, carburetor positioning, and brake fluid reservoirs across all four displacement variants.

Drivetrain specifications are addressed in sections covering chain guide wear inspection, sprocket tooth condition evaluation, and master link installation orientation. The document includes torque specifications for cylinder head fasteners, engine drain plugs, front axle retention, and rear axle nut security to ensure proper component alignment retention. Bolt and nut tightening reference data spans engine, chassis, and suspension mounting points across 33 critical fastener locations.

Reassembly procedures are specified for silencer packing replacement, including inner pipe rivet removal and new packing installation. Handlebar position adjustment, brake lever play configuration, and rear brake pedal position setup are documented with numerical clearance targets. Steering stem locknut adjustment methodology is provided alongside front fork upper and lower clamp bolt torque specifications, with step-by-step assembly sequence references for fork spring installation and suspension cap installation.

| System Category | Documented Content | Source Section |

|---|---|---|

| Fuel System | Octane rating requirements, oil mixing ratios, fuel tank capacity | Pages 71-72 |

| Cooling System | Radiator fin inspection, antifreeze mixture ratios, coolant drain plug procedures | Pages 78-80 |

| Electrical | CDI ignition timing reference marks, spark plug gap specifications | Pages 78, 81 |

| Drive System | Chain slack measurement (30-50 mm), sprocket wear limits, lubrication intervals | Pages 86-88 |

| Brake Systems | Disc diameter specifications, pad thickness minimum (1 mm), fluid type (DOT 3/4) | Pages 89-90 |

The manual documents torque specifications for the front brake caliper mounting bolts, disc plate fastening screws, and engine suspension mounting points to ensure proper structural integrity. Handlebar clamp bolt tension and steering head nut specifications are recorded with foot-pound equivalents for international reference. Suspension tuning guidance includes fork oil level adjustment methodology and rear shock preload range documentation, with settings calibrated for rider weight categories and track condition adaptation.

Troubleshooting reference material is organized by engine operation symptoms, transmission engagement issues, suspension performance complaints, and brake system effectiveness. The document provides diagnostic pathways for spark plug condition assessment (ceramic insulator color evaluation), fuel system obstruction identification, and cooling system pressure maintenance. Storage preparation sequences and post-storage reactivation checklists are detailed with lubrication point references and seasonal maintenance considerations for extended idle periods.

FAQ

Customer Reviews

Read what our customers say about this GASGAS Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)