New Holland EC 215 Excavator Service Manual (716 P.)

EC 215 hydraulic excavator service procedures, hydraulic system specifications, and component repair data. Complete technical handbook with pump controls, gearbox assemblies, and travel system maintenance (716 pages).

Manual Preview

Sample pages from the New Holland EC 215 Excavator Service Manual (716 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

New Holland EC 215 — Service Manual Technical Service Archive | EC 215 Series Repository.

- Prescribed Power Output Consumption Data: 119 kW is designed for the maximum engine rated horsepower Bounds.

- Standard Engine Operating Electrical Load: Operating envelope at 1900 rpm indicates the constant-speed duty framework Parameters.

- Core Compression Cold Start Limits: The cylinder head requires 17.5:1 for optimal combustion chamber compression Form Factor.

- Rated System Tightening Data: 390 bar (5660 psi) — controls the secondary pressure relief valve opening Topology.

- Technical Primary Pressure Power Rating: Primary relief valve setting of 350 bar provides essential system protection Matrix.

- Advanced Hydraulic Advanced Standards: Displacement volume of 107 cm³/revolution requires proper pump configuration Protocol.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Official Technical Manual: New Holland EC 215 Excavator Reference-Framework

Application-Range: New Holland EC 215 Excavator Systems // Specification-Class: Maintenance and Operations Documentation // Architecture-Focus: Multi-System Component Integration.

| System Category | Documentation Coverage | Specifications Included |

|---|---|---|

| Engine & Power Systems | 6BTA 5.9-C diesel engine specifications and operation parameters | Complete rated output, speed, and temperature data documented |

| Transmission & Drive Systems | 3-stage planetary final drive and 2-stage swing gearbox assemblies | Gear ratios, motor specifications, and load capacity reference data included |

| Hydraulic Circuit Architecture | Dual variable displacement pumps, servo systems, and control blocks | Pressure settings, flow rates, and system logic documented |

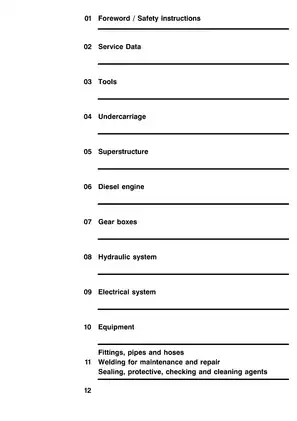

Outlining the operational framework across engine systems, transmission assemblies, hydraulic networks, and swing mechanisms, this manual encompasses the technical foundation required for comprehensive equipment maintenance and field operations. The document structures detailed system overviews including the dual pump architecture with load-limiting governor control, proportional demand pressure regulation, and integrated servo control networks spanning boom, stick, bucket, travel, and swing functions.

Properly mandating systematic service procedures, the manual contains maintenance intervals for hydraulic fluid changes, transmission gear oil replacement schedules, and filter element renewal specifications for both return-flow and charge-pressure circuits. Bolt torque specifications are documented for the traveling gearbox assembly connections, swing bearing attachment points, and superstructure securing fasteners to ensure proper fastener fatigue prevention. The document provides component identification data for hydraulic motors, cylinders, directional control valves, pressure relief assemblies, and accumulator precharge specifications across all operational circuits.

A detailed technical matrix emerges from system descriptions covering pressure-relief valve settings for primary and secondary protection stages, load-sensing control logic that manages pump displacement during multi-function operation, and regeneration circuits that enable pressureless boom lowering without energy consumption. The manual references specialized testing equipment including the PCS tester system for electronic control verification, pressure measurement adapters for system diagnostics, and stroke-measurement devices for proportional valve calibration. Each major component receives structured documentation including removal and installation sequencing, bearing preload adjustment procedures, seal replacement requirements, and component disassembly protocols with marked reference points to ensure proper reassembly orientation.

Operating procedures document both standard precision control ranging and high-power boost activation for intensive work loads, proportional pilot pressure generation for fine-grain equipment movement control, and emergency operational modes including manual boom lowering capability when hydraulic control fails. The superstructure holding brake system receives dedicated coverage describing spring-loaded multiple-disk braking design, solenoid valve release actuation through servo control pressure, and zero-speed sensor integration that prevents brake engagement during swinging motion.

Troubleshooting information covers hydraulic system flushing sequences following component failure and foreign material contamination, filter element inspection protocols for identifying damage types, and sequential pump operation during restoration following major service work. Special tools requirements are enumerated with complete part numbering for gearbox removal fixtures, bearing preload adjustment devices, and accumulator charging equipment, enabling proper technical support across service facilities.

FAQ

Customer Reviews

Read what our customers say about this New Holland Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)