Komatsu 95 Series Diesel Engine Workshop Manual

Comprehensive service documentation for 3D95S, 4D95L, S4D95L, 6D95L, S6D95L & SA6D95L engines with specifications, repair procedures, and maintenance standards.

Manual Preview

Sample pages from the Komatsu 95 Series Diesel Engine Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Komatsu 95 Series Diesel Engines (3D95S-W-1, 4D95L-1, 4D95S-W-1, 6D95L-1, S6D95L-1, SA6D95L-1) — 1998 Functional Engineering Documentation | Komatsu Series Module.

- Calibrated Displacement Data: Engine cylinder volumes range from 2,020 cc (3-cylinder) to 4,890 cc (6-cylinder) is specified as the total piston displacement Architecture.

- Measured Power Output: Maximum rated horsepower ranges from 35 HP to 118 HP depending on engine configuration delivers optimal performance Framework.

- Primary Torque Specification: Maximum torque output reaches 12.5–46.6 kgm at various engine speeds requires proper load management Standards.

- Specific Injection Equipment: Bosch PES-A type fuel injection pump is configured at centrifugal all-speed governor design Logic.

- Published Lubrication Data: Engine oil capacity is measured at 5.0–12.5 liters depending on model specification Margin.

- System Cooling Capacity: Coolant capacity reaches 9–22.3 liters establishing the thermal management Protocol.

Professional Workshop Service Manual & Technical Specifications

Applied Assembly Shop Manual: Komatsu 95 Series Diesel Engine Powertrain-Manual

Procedure-Type: 3D95S-W-1, 4D95L-1, 4D95L-W-1, 4D95S-W-1, S4D95L-1, S4D95LE-3, SAA4D95LE-3, 6D95L-1, S6D95L-1, SA6D95L-1 // Model-Designation: Direct fuel injection and swirl chamber diesel engines / In-line configurations Logic // Procedure-Type: 820 pages covering comprehensive service data with 14 major chapters.

| Component System | Documentation Scope | Reference Details |

|---|---|---|

| Engine Architecture | Cylinder block, crankshaft, camshaft, and piston assemblies | Complete specifications provided |

| Lubrication Network | Oil pump, filter, cooler, and distribution pathways | Chapter 11: Lubrication system procedures |

| Fuel Delivery | Injection pump calibration, nozzle pressures, and governor settings | See Chapter 12: Fuel system specifications |

| Thermal Management | Water pump, thermostat, radiator cooling circuits | Chapter 10: Cooling system data |

| Electrical Components | Alternator, starting motor, glow plug systems | Chapter 12: Electrical system wiring |

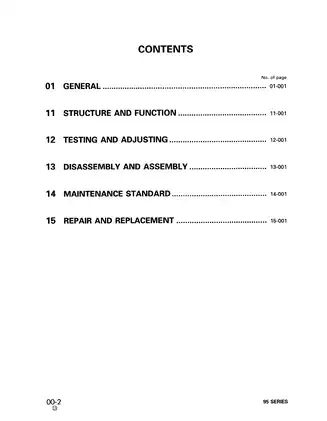

The repository is divided into general overviews, covering engine structure and function, testing procedures that validate combustion systems, disassembly and assembly sequences that govern component removal and installation, maintenance standards that establish inspection criteria, and repair and replacement guidance addressing component service requirements. Service sections detail intake and exhaust management including air cleaner operation and turbocharger function, complementing lubrication system arrangements and fuel injection pump calibration processes.

Precise Methodology

Methodically requiring attention to technical standards, the manual encompasses specifications for all engine model variants within the 95 Series family. The document addresses three-cylinder through six-cylinder configurations with detailed coverage of both precombustion chamber and direct fuel injection designs. Installation guidelines are provided for fuel injection systems, turbocharger assemblies, and coolant circulation networks across multiple machine applications from compact excavators to power generation equipment.

Comprehensive Architecture

The engine assembly documentation articulates camshaft-to-crankshaft timing relationships, piston ring configurations with hard-chrome plating specifications, and bearing material selections for primary and connecting rod journals. Maintenance guidelines are included for valve clearance adjustments specified in both hot and cold engine conditions, oil pressure monitoring across operating ranges, and coolant flow verification through all cooling passages. The manual documents torque specifications for bolt assemblies to ensure proper pivot-point integrity.

Engineered Parameters

OEM guidelines are included for fuel injection timing verification using both match-mark alignment and delivery valve methods applicable to different injection pump configurations. Technical data encompasses fuel consumption ratios measured in grams per horsepower-hour, governor performance curves demonstrating speed regulation across full operating ranges, and nozzle opening pressures calibrated between 120 and 225 kilograms per square centimeter depending on engine variant.

Advanced Nexus

Transmission service information covers coupling-type and flange-type fuel injection pump installations with specific adjustment procedures for engine stop motors and fuel cut solenoid clearances. The documentation includes electronic governor system control logic for alternator power generation applications, with circuit diagrams depicting load detection feedback systems and controller fault diagnosis protocols.

Systematic Parameters

HVAC system procedures are included for electrical intake air heater glow plug assemblies, with quick-glow controller wiring schematics and water temperature sensor calibration data. Comprehensive troubleshooting tables correlate symptom observations to probable causes across lubrication, cooling, fuel, electrical, and combustion systems, supporting systematic diagnostic methodology for field technicians and workshop service teams.

FAQ

Customer Reviews

Read what our customers say about this Komatsu Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)