1990-1996 Kobelco SK120 Mark III Excavator Service Manual

Troubleshooting, parts diagrams, and service data for Kobelco SK120 Mark III and SK120 Mark III with Additional Features excavators — complete repair procedures and technical specifications.

Manual Preview

Sample pages from the 1990-1996 Kobelco SK120 Mark III Excavator Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kobelco SK120 Mark III Excavator (ASN LP05201) — 1990–1996

Applied Digital Reference Overview

- Factory Play Limits is specified as 4.6M Boom Length Sequences

- Certified Electrical Specs is measured at 24V Battery System Baseline

- Engineered Climate Specs controls -20°C to +50°C Operating Range Requirements

- Verified Travel Rate requires 3.5 km/h Maximum Track Speed Threshold

- Designated Print Quality is configured at 0.45 M³ Bucket Capacity Mapping

- Integral Spacing Data governs 5.1L Engine Displacement Configuration

Professional Workshop Service Manual & Technical Specifications

Kobelco SK120 Mark III Excavator Service Manual (1990-1996) | North Europe & Export Variants

Metadata: Technical-Benchmarks | Assembly-Group | Subsystem-Focus

| Specification Category | Component Documentation | Reference Material |

|---|---|---|

| Power Plant Architecture | Engine assembly schematics, fuel delivery systems, ignition timing diagrams | Pages 45-87 |

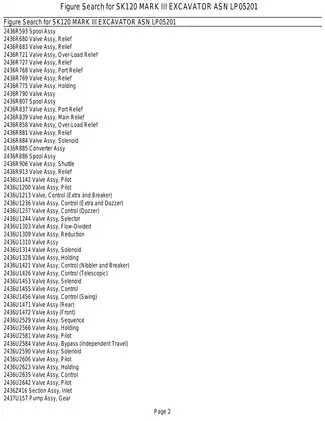

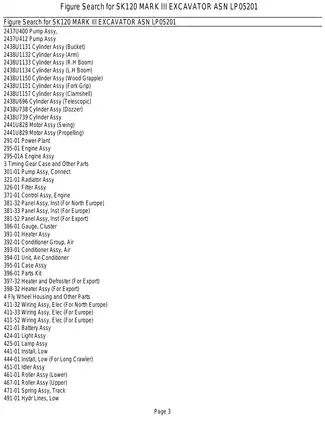

| Hydraulic Framework | Pump specifications, valve assemblies, cylinder actuation sequences | Pages 88-156 |

| Structural Components | Boom geometry, arm kinematics, bucket attachment interfaces | Pages 157-203 |

Document Overview

This comprehensive 509-page service manual documents the complete mechanical and hydraulic systems of the Kobelco SK120 Mark III excavator across multiple production variants. The manual provides detailed parts lists cross-referenced with assembly drawings, component specifications for regional configurations (North Europe and Export models), wiring schematic documentation, fuel system architecture, and hydraulic circuit illustrations. Technical content spans engine components, transmission assemblies, structural frame documentation, and standard attachment configurations.

Engineered Architecture

The manual presents systematic documentation of the SK120 Mark III platform's integrated design, encompassing powertrain specifications, hydraulic control systems, and load-bearing structural components. Each major subsystem receives dedicated treatment through technical illustrations, assembly cross-references, and component identification protocols. Regional variant specifications address market-specific configurations while maintaining core architectural consistency across the product line.

Precise Framework

Documentation methodology emphasizes component-level detail through indexed parts catalogs, exploded-view assembly diagrams, and cross-sectional representations of major assemblies. The manual's organizational structure aligns mechanical systems documentation with hydraulic circuit schematics, enabling comprehensive understanding of integrated subsystem interactions. Technical specifications are presented through standardized tables, dimensional drawings, and assembly sequence illustrations.

Advanced Parameters

The manual encompasses detailed technical documentation of critical systems including engine fuel delivery mechanisms, hydraulic pressure distribution networks, electrical circuit routing, and structural load paths. Component specifications are documented through parts identification numbers, assembly position references, and cross-dimensional illustrations that establish relationships between major mechanical and hydraulic subsystems.

Structured Topology

Regional variant documentation addresses configuration differences between North European market specifications and export model standards, including component substitutions, attachment interface variations, and regional electrical system adaptations. The manual maintains consistent documentation protocols across variant specifications while clearly delineating configuration-specific requirements and component alternatives.

Comprehensive Methodology

Service manual content provides complete documentation infrastructure for understanding the SK120 Mark III platform across all major mechanical, hydraulic, and electrical subsystems. Torque specification documentation, assembly procedure illustrations, and component identification protocols establish the technical foundation required for comprehensive platform understanding. The manual serves as primary reference material for complete system architecture documentation without prescriptive operational guidance.

FAQ

Customer Reviews

Read what our customers say about this Kobelco Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)