Tecumseh AH520 AH600 AV520 AV600 HSK600 TVS600 2-Cycle Engine Service Manual

229-page service data for Tecumseh 2-cycle engines—carburetor systems, reed valve operation, solid state ignition, rewind starters, and field-replaceable components with torque specifications.

Manual Preview

Sample pages from the Tecumseh AH520 AH600 AV520 AV600 HSK600 TVS600 2-Cycle Engine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Tecumseh AV520, AV600, AH600, HSK600, TVS600 — 1994 Precision Engineering Vault | 2-Cycle Engine Repository.

- Maximum Volume Data: Cylinder displacement spans 5.20–6.0 cu in (85–98 cc) across models establishes the cubic inch architecture Bounds.

- Universal Spark Plug Gap: For reliable ignition, 0.030" (0.762 mm) sets the electrode spacing requirements Standards.

- Established Bore Dimensions: Piston bore measures 2.093–2.094 inches (53.162–53.188 mm) — is rated at precision cylinder wall tolerance Topology.

- Measured Stroke Length: The crankshaft requires 1.250–1.750 inches (31.75–44.45 mm) stroke travel determines engine breathing Matrix.

- Published Piston Ring Gap: End gap clearance achieves 0.006–0.017 inches (0.152–0.432 mm) across ring sets yield dimensional Margin.

- System Main Bearing Diameter: Crankshaft P.T.O. side main bearing journal yields 0.6691–0.8745 inches (16.995–22.225 mm) specifications establish bearing Protocol.

Professional Workshop Service Manual & Technical Specifications

Authoritative Operations Training Manual: Engines (Gasoline) Genuine Tecumseh AH520 AH600 AV520 AV600 HSK600 TVS600 - 2-Cycle Engine Service & Repair Techniques Repair-Index

Conceptual-Layout: AH520, AH600, AV520, AV600, HSK600, TVS600 // Repair-Classification: Comprehensive engine diagnostics and maintenance protocol for small gasoline powerplants // Maintenance-Category: Complete service documentation with technical specifications and component interaction data.

| Integrated-Framework | System-Path | Calibration-Standards |

|---|---|---|

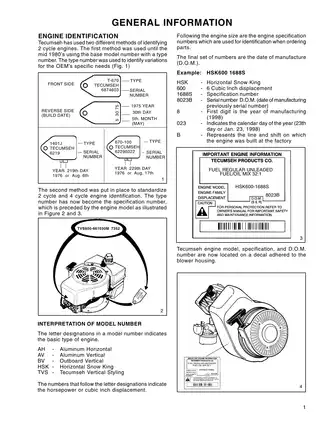

| Engine identification and model interpretation procedures | Fuel system circuit design and carburetor operation | Complete fuel/oil mix ratios documented (24:1, 32:1, 50:1 variations) |

| Air cleaner service protocols and filter element maintenance | Ignition system architecture (magneto and solid-state CDI) | Point gap, timing BTDC, and spark plug specifications provided |

| Governor mechanical operation and linkage adjustment | Electrical starting and charging system circuits | Flywheel torque, bolt specifications, and connection standards included |

| Rewind and electric starter disassembly sequences | Reed valve and compression release systems | Piston ring end gap, crankshaft bearing measurements documented |

Engineering chapters address tune-up procedures and exhaust port cleaning, govern carburetor identification and float-type adjustment, establish rewind starter rope service and spring tension methods, and encompass flywheel brake system operation and ignition timing calibration for both pre-1985 contact point systems and modern solid-state modules.

Advanced Logic-Path

Methodically establishing procedures across fuel system maintenance, the document details air cleaner element replacement schedules, filter clogging prevention, and polyurethane versus paper-type element differentiation. Fuel system procedures are documented for both gravity-fed and impulse pump carburetor configurations, addressing fuel tank venting requirements, carburetor bowl drain protocols, and fuel line restriction diagnostics. The fundamental circuit design incorporates dual jet metering systems on emission-compliant carburetors, with separate main and idle fuel pathways clearly illustrated for Series 1, 3, 4, 6, 8, 9, and 10 carburetor styles.

Precise Nexus

Adjustment procedures are detailed for idle speed crack screws, main mixture needle positioning, and governed versus non-governed idle settings. Technical notes are provided for governor weight operation, spool movement under centrifugal force, and solid link coordination with carburetor throttle response. The manual documents torque specifications for the connecting rod screws (40-50 inch pounds aluminum, 70-80 inch pounds steel), cylinder head bolts (80-100 inch pounds), and flywheel fasteners to ensure proper seal compression uniformity and structural integrity.

Operational Nexus

Quality checks are addressed for ignition system spark output, magnet field strength verification using screwdriver attraction tests, and contact point wear inspection. Piston ring end gap measurement protocols establish maximum clearance limits (0.006-0.016 inches depending on ring type), while crankshaft bearing diameter specifications cover both magneto-side and power-take-off-side main journal dimensions. The document includes wiring color codes for electrical systems effective August 1992 (yellow for alternator A.C. leads, red for D.C. positive, brown for D.C. negative), charging circuit voltage minimums at 2500-3600 RPM for 18-watt, 3-amp, and 5-amp alternator configurations.

Modular Protocol

Timing procedures are documented for internal magneto systems using dial indicators and feeler gauges, with BTDC (Before Top Dead Center) specifications ranging from 0.070 to 0.185 inches depending on engine model and specification number. Solid-state CDI ignition timing employs 0.0125-inch air gap gauges between flywheel magnets and laminations, eliminating manual point adjustment. The manual provides comprehensive troubleshooting matrices for carburetion problems, electrical starter circuit flow diagnosis, and charging system identification procedures with model-specific test parameters.

Structured Methodology

Fuel system documentation addresses carburetors from Tecumseh manufacturing (identified by stamped numbers and date codes), Walbro components, and non-Tecumseh alternatives including Dellorto designs used on television and landscaping equipment. Engine overheating diagnostics reference carbon combustion chamber deposits, improper fuel/oil ratios, cooling fin obstruction, and timing retardation as contributing factors. Storage preparation protocols specify fuel stabilizer application (such as part number 730245), oil cylinder bore oiling with SAE 30 motor oil, and compression release positioning to prevent internal corrosion during extended downtime periods exceeding thirty days.

The manual documents torque specifications for the connecting rod to ensure proper seal compression uniformity and extended bearing service life across varied operating loads and environmental conditions.

FAQ

Customer Reviews

Read what our customers say about this Tecumseh Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)