1989 Toro Power Shift 624 / 824 / 828 / 1132 Service Manual

Complete service manual for Toro Power Shift Snowthrower models 624, 824, 828, 1132. Covers transmission operation, auger/impeller systems, and engine specifications for Mitsubishi, Tecumseh, and Briggs & Stratton powerplants. (105 P.)

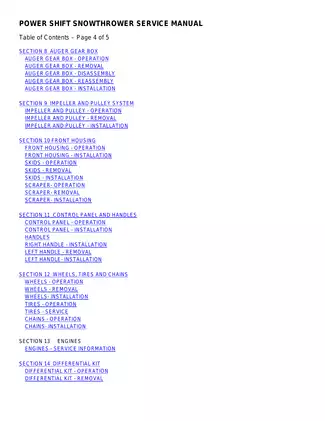

Manual Preview

Sample pages from the 1989 Toro Power Shift 624 / 824 / 828 / 1132 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Toro 624, 824, 828, 1132 Power Shift Snowthrower — 1989–1990 Technical Service Archive | Power Shift Snowthrower Series Kit.

- Certified Scan Resolution: Impeller throat diameter is specified as 14.0 cm (5.5 inches) fundamental to snow discharge Architecture.

- Measured Tightening Data: For optimal fastening, 1.38 kg·m (120 in·lbs) governs auger gearbox screw torque Standards.

- Designated Storage Capacity: The auger gearbox requires 0.133 liters (4.5 ounces) of SAE 90 EP gear oil Margin.

- Engineered Electrical Specs: Tire pressure is designed for 0.5–1.0 kg/cm² (7–15 psi) on pneumatic wheels Protocol.

- Primary Thermal Rating: Auger speed establishes 125–126 rpm for optimal snow feed control Architecture.

- Baseline Addressable Resolution: Auger housing width sets 53.3 cm (21.0 inches) as the standard cutting dimension Norms.

Professional Workshop Service Manual & Technical Specifications

Complete Reference Manual: Toro Power Shift Snowthrower 624, 824, 828, 1132 Engineering-Archive

Model-Specs: Toro 624, 824, 828, 1132 Power Shift Snowthrower models // System-Coverage: Multi-engine transmission and control system logic // Architecture-Focus: Complete technical documentation with 19 sections covering all service procedures.

| Documentation Role | Chapter Coverage | Technical Reference |

|---|---|---|

| Service Specifications Index | Model identification, engine data, torque requirements | Complete specifications provided |

| Component System Breakdown | Control systems, transmission, auger, impeller, wheels | See respective sections |

| Reference Topics | Maintenance schedules, troubleshooting logic, part listings | All documented |

Repair procedures are structured around specifications for models 38500, 38505, 38510, 38513, 38520, 38525, 38540, 38543, 38545, 38565, 38570, 38573, and 38580, with engine manufacturers including Mitsubishi, Tecumseh, and Briggs & Stratton. The manual covers power shift controls with detailed latch release mechanisms, reverse control operation, shift lockout systems, and indexing mechanisms that document the alternating wheel movement during power shifting. Traction and impeller controls are addressed separately, detailing the locking mechanism that enables single-hand operation when both systems are engaged simultaneously. The discharge chute system documentation includes the constant velocity joint transmission and worm gear assembly that document the 200-degree rotation capability.

Factory specifications are documented for the transmission assembly, including the six-system architecture comprising input system, bevel gears, fixed gear cluster, selectable gear cluster, shift mechanism, and speed reduction gear set. The manual includes detailed information on the two-stage auger design operating at 125-126 rpm and the impeller system rotating at approximately 1250 rpm. Idle system components—traction and impeller idler pulleys with spring-tensioning, brake arm assemblies, and over-tensioning prevention springs—are fully documented. Drivetrain specifications are addressed in dedicated sections covering the pivot system allowing wheel swing capability, latch system retention, and chain tension maintenance.

Reassembly procedures are specified for the power shift control box components including reverse bellcrank assemblies, index wheel mechanisms, latch lever systems, and lockout base installations. Service intervals are documented for drive chain adjustment (after every 25 hours), spark plug service (after 25 hours), crankcase oil changes (initial after 2 hours, then every 25 hours), and chain lubrication performed annually. The manual documents torque specifications for critical fasteners including traction gear case screws, pivot arm shoulder bolts, auger gearbox screws, control box nuts, and belt guide screws to ensure proper assembly integrity.

The document includes comprehensive troubleshooting sections addressing unit propulsion issues, shift lever lockout function, wheel indexing during power shifting, transmission operation, scraper wear patterns, and snow discharge obstruction. Engine service information references specifications for Mitsubishi, Tecumseh, and Briggs & Stratton engines, with documentation noting that complete engine servicing procedures are published separately by manufacturers. Optional accessory documentation covers light kit models 66-7930 (Tecumseh), 66-7940 (Briggs & Stratton), 66-7950 (Mitsubishi), differential kit model 38038 with locking capability, snow cab kits 66-6200 and 68-9500, and drift breaker assembly. The manual documents torque specifications for the auger gearbox to ensure proper vibration dampening.

FAQ

Customer Reviews

Read what our customers say about this Toro Snow Blower manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)