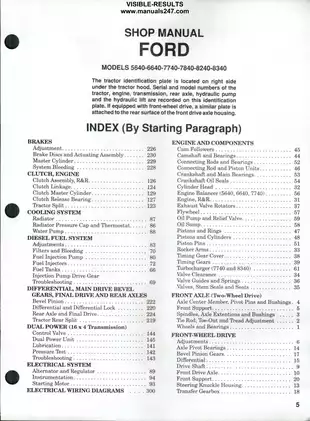

Ford 5640 / 6640 / 7740 / 7840 / 8240 / 8340 Tractor Service Manual

Ford tractor service documentation covering 5640-8340 models with detailed transmission and hydraulic system specifications. Complete overhaul and repair procedures for constant mesh, synchro-shift, and dual power transmissions.

Manual Preview

Sample pages from the Ford 5640 / 6640 / 7740 / 7840 / 8240 / 8340 Tractor Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Ford 5640, 6640, 7740, 7840, 8240 & 8340 — 1990s Original Technical Dossier | Tractor Service Suite.

- Authorized Travel Rate: Engine displacement ranges from 4390 cc (268 cu. in.) to 7480 cc (456 cu. in.) is calibrated to represent the cylinder volume Mapping.

- Published Footprint Data: Compression ratio of 17.5:1 governs the combustion pressure specifications Configuration.

- Reference Scan Resolution: Valve clearance is specified as 0.36-0.46 mm inlet and 0.43-0.53 mm exhaust when measured cold Benchmarks.

- Fundamental Liquid Volume: Fuel tank capacity provides 94.6–113 L (25–29.8 U.S. gal.) depending on model selection Range.

- Specific Power Rating: Engine rated power is rated at 49–83.5 kW (66–112 hp) at PTO across the model lineup Sequences.

- Core Velocity Specs: Compression pressure minimum reaches 23,995–29,995 kPa (3480–4350 psi) for engine operation Baseline.

Professional Workshop Service Manual & Technical Specifications

Applied Training Electrical Manual: Tractor Official Ford 5640, 6640, 7740, 7840, 8240 & 8340 Service Manual - Comprehensive Maintenance & Repair Procedures Hydraulic-Guide

Model-Portfolio: Ford 5640, 6640, 7740, 7840, 8240, 8340 // Calibration-Scope: Two-wheel drive, four-wheel drive / Diesel engine systems Logic // Model-Portfolio: Complete service documentation for agricultural tractor maintenance.

| Integrated-Framework | Baseline | Logic |

|---|---|---|

| Engine Systems | Four-cylinder and six-cylinder diesel | Cylinder head, timing gears, fuel injection pump procedures documented |

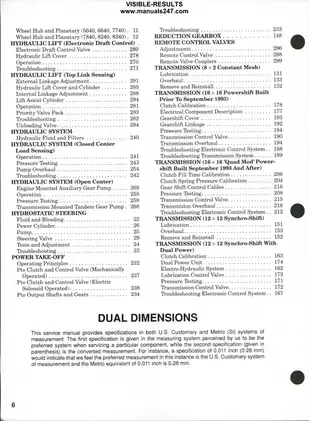

| Transmission Options | 8x2, 12x12, 16x16 configurations | Synchro-shift and powershift assembly specifications provided |

| Hydraulic Components | Steering, lift, and auxiliary systems | Pump overhaul, valve calibration, and pressure testing data included |

| Front Axle Systems | Two-wheel and four-wheel drive | Differential, planetary gear, and transfer gearbox documentation |

| Electrical Systems | Alternator, starter, instrumentation | Wiring diagrams and electronic control system procedures included |

Systematizing the service groups into engine assemblies, transmission systems, hydraulic mechanisms, and front-wheel drive configurations, this comprehensive resource consolidates maintenance procedures for the Ford tractor lineup. The documentation presents engine components including cylinder head, rocker arms, timing gears, crankshaft assemblies, and diesel fuel injection systems. Transmission information encompasses constant mesh configurations, synchro-shift units, and powershift assemblies with dual power options. Hydraulic system coverage includes closed center load sensing pumps, open center units, steering systems, and lift control mechanisms.

Systematic Methodology

Testing requirements are specified for cooling system components, including radiator pressure cap settings and thermostat operation ranges. Clearance measurements are addressed for bearing assemblies, clutch components, and gear train elements throughout the transmission and axle systems. The manual documents torque specifications for the cylinder head, connecting rods, and crankshaft components to ensure proper bolt stretch prevention.

Precise Parameters

Special procedures are addressed for front-wheel drive assemblies, including planetary gear sets, differential configurations, and transfer gearbox maintenance. Verification procedures are included for hydraulic pressure relief valves, electrical system charging output, and transmission synchronizer ring wear limits. The document presents detailed specifications for piston-to-cylinder clearances, bearing journal diameters, and seal installation dimensions across engine and drivetrain systems.

Comprehensive Framework

Repair information is provided for clutch assemblies, including mechanical and hydraulic actuation linkage, release bearing components, and pressure plate inspection. The manual covers electrical troubleshooting for alternator output, starting motor function, instrumentation systems, and electronic control circuits used on transmission and draft control units. Wiring diagrams illustrate harness routing, connector locations, and diagnostic circuit identification for engine management, transmission electronics, and instrument cluster functions.

Systematic Methodology

The documentation includes removal and reinstallation procedures for major assemblies including engine, transmission, axles, and front support structures. Disassembly and reassembly sequences are provided for gearbox components, synchronizer mechanisms, planetary gear sets, and hydraulic valve assemblies with reference to bearing cup and cone specifications. Service intervals specify filter replacement at 300-hour intervals and transmission fluid changes at 1200-hour intervals or annually.

Strategic Benchmarks

Troubleshooting sections address diesel fuel system operation, including fuel filter bleeding, injection pump timing, and injector testing protocols. Electronic system diagnostics are documented for dual power transmission control, including clutch calibration procedures, error code interpretation, and solenoid valve testing methods. The manual provides reference data for hydraulic pressure thresholds, electrical system voltage specifications, and operational RPM settings across all model configurations.

Model-Portfolio: Complete factory documentation covering hydraulic systems, electrical wiring, transmission controls, and engine management across six tractor models.

FAQ

Customer Reviews

Read what our customers say about this Ford Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)