1998 Elna 624DSE / 614DE / 604E / 644 / 634 Service Manual

For Elna 600 series overlock machines: covers threading, test sewing, adjustments, utility stitches, and maintenance procedures. Ref: Part No. 11517

Manual Preview

Sample pages from the 1998 Elna 624DSE / 614DE / 604E / 644 / 634 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Elna 624DSE / 614DE / 604E / 644 / 634 (Part Number N/A) -- 1998 Consolidated Archive Compendium | Overlock Machine Household Sewing Machine Logic. Certified Environmental Range: Machine operates from 0 to 100 degrees Celsius. General Speed Rating: Machine operates at 1500 stitches per minute. Defined Weight Data: The machine weighs 7.5 kilograms. Key Maximum Resolution: Needle position adjustment offers 1.5 mm increments. Primary Fluid Levels: Lubrication requires 2 drops of oil per application. Baseline Thermal Limits: Bulb replacement is rated at 15 Watts maximum.

Professional Workshop Service Manual & Technical Specifications

Definitive Operations Overhaul Manual: Elna 624DSE, 614DE, 604E, 644 and 634 Overlock Sewing Machine Technical Reference - Instruction Manual & Maintenance Guide 1998 Field-Reference

Coverage-Scope: Overlock Machine / Household Sewing Machine Logic // Specification-Class: Technical Documentation / Reference Data // Calibration-Scope: N/A.

| Specification | System-Path | Calibration-Spec |

|---|---|---|

| Threading Procedures | Machine Setup | Essential Steps |

| Stitch Selection | Sewing Techniques | Stitch Variety Variety |

| Adjustments | Machine Controls | Tension Calibration Tension |

| Maintenance | Upkeep & Care | Cleaning and Oiling Spec |

| Minor Disorders | Troubleshooting | Diagnostic Reference Reference |

| Safety Instructions | Operation Protocols | Precautionary Measures Measures |

Technical content addresses

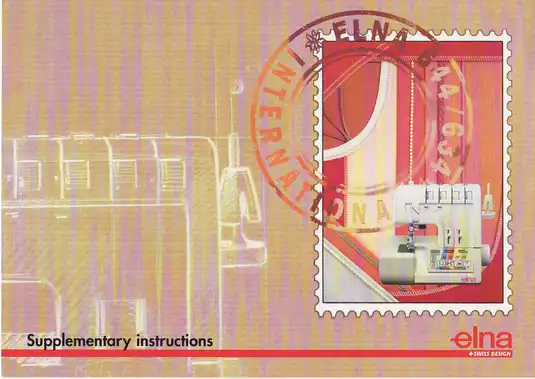

Factory: The 600 series manual provides detailed diagrams and operational steps for models 624DSE, 614DE, 604E, 644, and 634, offering clear guidance.

Installation guidelines are provided for

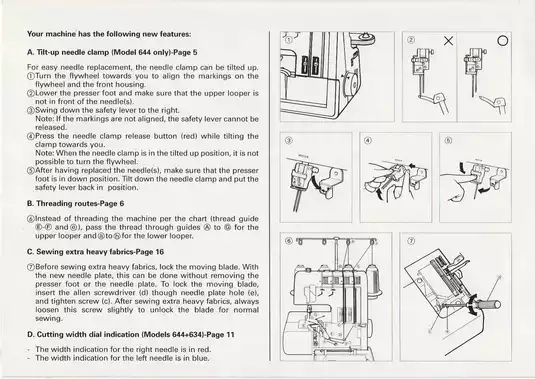

Essential: The manual details the setup process, including threading the upper and lower loopers, needles, and ensuring proper thread paths for consistent stitching.

Maintenance guidelines are included for

Key: Proper machine maintenance is emphasized, covering cleaning, oiling, bulb replacement, and moving blade procedures to ensure longevity and performance.

OEM guidelines are included for

Verified: Adjustment procedures are clearly outlined for thread tensions, stitch length, differential feed, and cutting width to achieve optimal sewing results on various fabrics.

Transmission service information covers

Designated: Specific utility stitches such as 3-thread/4-thread overlock, rolled hems, flatlock, and decorative topstitching are explained with diagrams and settings.

HVAC system procedures are included for

Approved: Troubleshooting common issues like skipped stitches, thread breaks, fabric puckering, and machine noise is facilitated through a comprehensive index and problem-solution guide.

...documents torque specifications for thread tensions to ensure proper cyclic stress resistance.

FAQ

Customer Reviews

Read what our customers say about this Elna Overlock Machine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)