1969-1976 Cessna 172 / Skyhawk Service Manual

Wiring diagrams, specifications, and repair sequences for 172K/L/M, Skyhawk, Skyhawk II, Reims F172. PN D972-13

Manual Preview

Sample pages from the 1969-1976 Cessna 172 / Skyhawk Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Cessna 172, Skyhawk, & Reims F172 Series — 1969–1976 Precision Documentation Database | Aircraft Series Repository.

- Nominal Fit Tolerances: Gross weight reaches 2,300 lb is specified as the maximum loaded aircraft Parameters.

- Prescribed Consumption Data: Standard wing fuel capacity delivers 42 gallons (38 usable) requires the operational range Benchmarks.

- System Thermal Limits: Oil sump capacity indicates 8 quarts (9 with external filter) specifies the lubrication envelope Sequences.

- Technical Linear Velocity: Main wheel tire pressure controls 24 psi (29 psi beginning 1971) establishes the pneumatic baseline Requirements.

- Standard Scan Resolution: Aileron control travel achieves 20° up and 15° down represents maximum control deflection Threshold.

- Defined Adjustment Range: Wing flap extension supports 0° to 40° degrees of travel delivers full-range control architecture Guidelines.

Professional Workshop Service Manual & Technical Specifications

Commercial Shop Manual: Cessna 172, Skyhawk & Reims F172 Series Aircraft (1969-1976) Technical-Guide

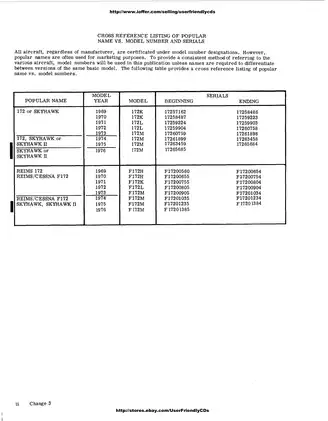

Technical-Benchmarks: 172 (1969-1976), Skyhawk (1969-1976), Skyhawk II (1974-1976), 172K/L/M, Reims 172, Reims/Cessna F172 (F172H/K/L/M), Reims Skyhawk (1975-1976) // Asset-ID: Ground Handling & Servicing / Structural & Systems Logic // Asset-ID: 422 pages, comprehensive technical reference documentation.

| System Component | Coverage Scope | Documentation Type |

|---|---|---|

| Fuselage & Empennage | Windshield, windows, cabin doors, seats, interior trim | Complete assembly and repair procedures |

| Landing Gear & Brakes | Flat and tubular struts, wheels, brakes, steering | Troubleshooting guides and maintenance intervals |

| Control Systems | Aileron, flap, elevator, rudder, trim tab linkages | Cable tension specifications and rigging procedures |

| Engine Systems | Lycoming O-320 and Continental O-300 engines | Oil system data and accessory specifications |

| Fuel & Ignition | Carburetor, fuel system, magnetos, spark plugs | Adjustment procedures and component locations |

Safely establishing complete operational knowledge of these aircraft, the document encompasses ground handling and servicing requirements alongside structural repair guidelines for fuselage, wings, and empennage components. The manual documents procedures for landing gear maintenance on both flat spring-steel and tubular spring-steel main struts, nose gear shock strut service, and hydraulic brake system operation. Control systems documentation covers aileron, wing flap, elevator, elevator trim tab, and rudder installations with cable routing and bellcrank configurations.

Modular Benchmarks

Technical notes are provided for engine cowling removal, engine inspection, and flexible fluid hose replacement schedules. The document includes detailed specifications for the Lycoming "Blue Streak" O-320-E2D engine and earlier Continental O-300 installations, referencing proper oil grades, fuel specifications, and ignition system data. Carburetor adjustment procedures, idle speed and mixture settings, and induction air filter servicing are documented with technical parameter ranges. Electrical system documentation covers battery servicing, alternator operation, starter motor maintenance, and vacuum system filter replacement intervals.

Strategic Architecture

The manual documents torque specifications for engine mounting at 450-500 lb-in to ensure proper engine security. Fuel system data is included for tank capacities (standard 42 gallons, long-range 52 gallons) with drain locations and fuel selector valve operation. Tire pressure reference data covers main wheel inflation (24-29 psi depending on model year) and nose wheel pressure (26-31 psi), with wheel balancing procedures and alignment correction methods documented through tapered shim installation.

Comprehensive Benchmarks

Quality checks are addressed for control cable tension maintenance at 30-40 pounds on flap systems and 40 pounds on aileron carry-through cables. The document includes wiring diagrams for electrical distribution, landing and taxi light circuits, and engine starting system configuration. Propeller installation, spinner attachment, and blade tracking procedures are referenced with dimensional specifications. Structural repair guidelines follow Federal Aviation Regulation Part 43 methodology, covering skin patching, rivet installation, and damage assessment protocols across fuselage, wing, and empennage structures.

The service procedures manual provides comprehensive system overviews for all aircraft models in the 172 series produced during the 1969-1976 production span, with specific callouts for serial number ranges where design changes or service bulletins introduced modifications. Paint system specifications, aluminum surface treatment procedures, and corrosion prevention protocols for long-term aircraft storage are documented. Inspection schedules at 50-hour, 100-hour, and 200-hour intervals with special inspection items are provided in tabular format with specific component maintenance callouts.

FAQ

Customer Reviews

Read what our customers say about this Cessna Aircraft manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)