Snapper 1600 / 1650 / 1855 Garden Tractors & Mower Attachments Service Manual

Complete service guide for all Snapper garden tractor models including steering, transmission, hydraulic systems, and mower drives. Covers maintenance, adjustment, and repair procedures with detailed diagrams and torque specifications. PN #07005

Manual Preview

Sample pages from the Snapper 1600 / 1650 / 1855 Garden Tractors & Mower Attachments Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Snapper 1600, 1650, 1855 Garden Tractors — 1980s Systematic Technical Briefing | Snapper Series Repository.

-

Factory Deviation Limits: Fuel tank capacity reaches 2.75 gallons (10.4 L) is standardized to primary fuel storage Mapping.

-

Measured Energy Draw: For hydraulic operation, 700–800 psi defines the lift system relief pressure Configuration.

-

Essential Environmental Range: Wheel bearing retaining specifications — is rated at 15–20 ft·lbs (20.3–27.1 N·m) Benchmarks.

-

Verified Rotation Data: The blade attachment assembly requires 45 ft·lbs (61 N·m) torque for proper fastening Range.

-

Designated Native Resolution: Spindle housing retaining bolts sets 30–35 ft·lbs (40.7–47.5 N·m) as required fastening Sequences.

-

Approved Fit Tolerances: Gear engagement backlash specifies 0.002–0.005 inches (0.051–0.127 mm) maximum tolerance Baseline.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Service Shop Manual: Lawn and Garden Tractor Complete Snapper 1600, 1650, 1855 Garden Tractors & Mower Attachments - Comprehensive Maintenance & Repair Manual Specification-Guide

Operational-Framework: Snapper 1600, 1650, 1855 series tractors and mower attachments // Unit-Designations: Lawn and garden tractor systems and subsystems // Operational-Framework: Service manual technical content for maintenance and repair procedures.

| Assessment-Element | System-Path | Calibration-Standards |

|---|---|---|

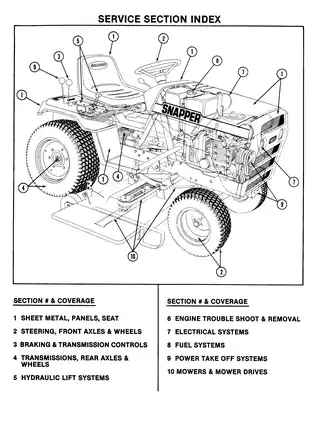

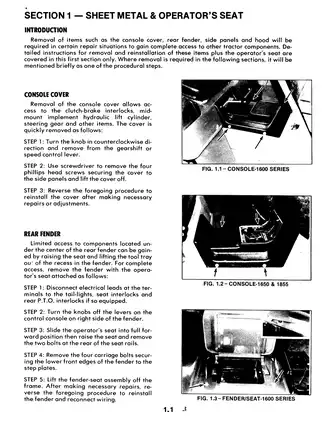

| Sheet Metal & Panels | Operator comfort and frame access | Console, fender, seat removal/installation documented |

| Steering Systems | Front axle and control assemblies | Gear assembly, linkage, and spindle procedures included |

| Transmission & Drives | Hydrostatic and gearbox units | Control linkage adjustments and troubleshooting documented |

| Engine Systems | Ignition, fuel, and exhaust components | Carburetor adjustments and governor settings referenced |

| Hydraulic Lift Systems | Pressure control and cylinder operation | Relief valve and component reconditioning specifications |

| Mower Attachments | Belt-driven and gear-driven units | Blade timing, spindle repair, and drive adjustment procedures |

Service procedures are grouped by engine and transmission type, covering troubleshooting and maintenance for the 1600 mechanical transaxle configuration, repair information is provided for the 1650 and 1855 hydrostatic drive systems, the document includes coverage of steering adjustment on both sector shaft and rotary gear designs, brake system specifications are included for disc and band brake mechanisms, and safety procedures are documented for initial setup and operational checks.

Structured Parameters

Verification procedures are included for interlock switch operation, neutral return functionality, and forward/reverse pedal responsiveness. The manual establishes the analytical sequence for engine service, from spark plug and breaker point inspection through carburetor idle and main fuel adjustment. Safely requiring proper component identification, the transmission troubleshooting guide presents erratic motion, torque loss, and noise complaints alongside potential internal leakage and valve malfunction scenarios.

Integrated Framework

Repair information is provided for bellcrank arm bearing replacement, axle pivot bushing removal, and spindle arm bushing installation on both 1600-1650 and 1855 series front suspension assemblies. The document includes coverage of charge pump disassembly, motor rotor ball-piston handling, and valve body component service for hydrostatic transmission systems. Hydraulic lift cylinder reconditioning procedures are documented with piston rod removal, O-ring replacement, and seal installation sequences.

Structured Logic-Path

Brake system specifications are included for disc brake pad replacement, caliper pin inspection, and clearance adjustment on hydrostatic drive models, as well as brake band drum replacement on 1600 series tractors. Control valve pressure adjustment, relief valve component inspection, and spool body service are outlined with O-ring and shim management protocols. The manual documents torque specifications for belt tensioning on 42" and 48" mowers to ensure proper spindle alignment.

Operational Logic-Path

Safety procedures are documented for fuel system service, including shut-off valve operation and fuel line routing to prevent contact with rotating engine components. Interlock switch testing procedures verify seat safety engagement, clutch pedal depression, and PTO switch status before engine cranking conditions are satisfied. The electrical system section includes alternator charging system diagnostics, circuit breaker function, and ammeter ground continuity checks.

Engineered Logic-Path

The document presents mower attachment specifications covering blade timing geometry (parallel outer blades, perpendicular center blade), spindle bearing and seal replacement methods, and gearbox backlash adjustment for 54" mid-mount units. Engine removal and installation procedures differ between single-cylinder and twin-cylinder models, addressing fuel tank access, drive coupler disconnection, and traction belt tension adjustment. Component identification figures reference assembly sequence, bearing orientation, and seal lip positioning for reassembly accuracy across transmission, axle, and brake assemblies.

FAQ

Customer Reviews

Read what our customers say about this Snapper Lawn and Garden Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)