2006-2011 Liebherr L550-L580 2plus2 Service Manual

Diagnostic procedures and component service for Liebherr L550-L580 2plus2 wheel loaders from 2006-2011. This manual covers maintenance and repair. Part number 1035-3357.

Manual Preview

Sample pages from the 2006-2011 Liebherr L550-L580 2plus2 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Liebherr L550-L580 2plus2 (1035-3357) – 2006-2011 Technical Reference | Series 2plus2 / Serie 6 Kit

- Design: 3.2 m³ establishes the standard bucket capacity as per ISO 7546 Data.

- Specific Temperature Range: For optimal operation, 111-200 kW (150-272 HP) defines the engine output Framework.

- Essential Power Rating: 275-430 L -- signifies the standard fuel tank capacity Threshold.

- Advanced Memory Capacity: The electronics require 24 V for standard operation Logic.

- Core Speed Performance: Maximum travel speed reaches 40 km/h Parameters.

- Design: 1150+ pages provides comprehensive technical documentation for the L550-L580 series.

Professional Workshop Service Manual & Technical Specifications

Integrated Installation Parts Manual: Wheel Loader Professional Liebherr L550-L580 2plus2 Wheel Loader Service Manual – 1150+ Pages | Pro Service File Standards-Vault

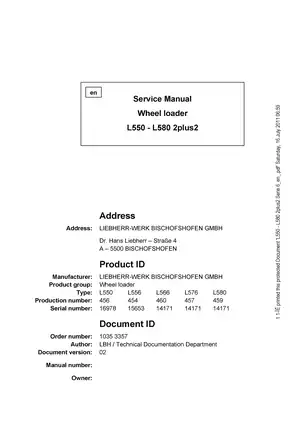

Coverage-Scope: 2006-2011 Liebherr L550 / L556 / L566 / L576 / L580 2plus2 Series 6 | Assembly-Group: Wheel Loader / Diesel Engine Logic | Engineering-Metrics: 758 pages, 190.489 MB

Technical Data

| Integrated-Framework | System-Path | Framework |

|---|---|---|

| Primary Models | L550-L580 | 2plus2 |

| Production Range | 2006-2011 | Serie 6 |

| Engine Model | D934/D936 | Diesel |

| Power Output | 111-200 kW | 150-272 HP |

| Fuel Tank Capacity | 275-430 L | Standard |

Maintenance hierarchies are structured into

Chapter 1: General Information Covers essential safety regulations, introduction to the manual, and special tools required for maintenance and repair. It details symbols and their meanings.

Chapter 2: Production Description Provides a comprehensive overview of the machine's technical data, including specifications for different models, engine details, and capacities.

Chapter 3: Maintenance This section details the maintenance and inspection schedule, testing and adjustment plans, and lubrication charts, ensuring the machine operates efficiently.

Chapter 4: Diesel Engine, Splitter Box Focuses on the diesel engine components, electrical systems, fuel system, air filter system, and couplings. It includes technical data and design descriptions.

Chapter 5: Hydraulics and Pneumatics This chapter covers hydraulic systems, including travel hydraulics, working hydraulics, steering systems, and brake systems, along with associated components and testing procedures.

Correctly demanding. This manual documents torque specifications for various components to ensure proper pressure slip prevention.

FAQ

Customer Reviews

Read what our customers say about this Liebherr Wheel Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)

I want to buy LIEBHERR L550 L556 L566 L576 L580 2PLUS2 WHEEL LOADER SERVICE MANUAL

but I have no paypal card.Is it possible to pay T/T against pro forma Invoice ?

Pls let me know,

Sandu Ion

General Manager

SC SANDUNAV INTERMED SRL

Address : Str.V. Alecsandri 3 , Oltenita, Romania , 915400 , jud. Calarasi

Tel/ Fax :+40 342 220021

Mobile : +40 740901115

+40728380017

email : sanduion1@yahoo.com

https://www.reparatii.bizoo.ro

ID skype : sandy201228