Elna Lock PRO DC/DE Series Service Manual

Essential technical reference covering Elna PRO 4 DC, PRO 4 DE, PRO 5 DC, and PRO 5 DE models. Includes detailed adjustment procedures and diagnostic charts for optimal performance. Part number 396900-02.

Manual Preview

Sample pages from the Elna Lock PRO DC/DE Series Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Elna Lock PRO DC/DE Series Service Manual | Reference Data Elna PRO 4 DC, PRO 4 DE, PRO 5 DC, PRO 5 DE (Service Manual) | Reference Data

- Nominal Speed Rating: 1400 RPM is rated at maximum speed on "Hare" setting.

- Principal Travel Rate: 650 RPM is calibrated to minimum speed on "Tortoise" setting.

- Rated Net Mass: The machine weighs 7.4 kg (16.3 lbs).

- Technical Assembly Torques: Specific torque values are detailed for component assembly to ensure proper seal integrity.

- Standard Adjustment Range: Differential feed adjustment ranges from 0.5 to 2.0 for even fabric feeding.

- Defined Cold Start Limits: The fuse is rated at 3.15A/250V for 230V operation.

Professional Workshop Service Manual & Technical Specifications

Elna Lock PRO DC/DE Series Service Manual: Elna PRO 4 DC, PRO 4 DE, PRO 5 DC, PRO 5 DE Service Manual - Comprehensive Repair Procedures

System-Identifier: PRO 4 DC, PRO 4 DE, PRO 5 DC, PRO 5 DE // Year-Coverage: 1991 // Operational-Framework: Sewing Machine Logic.

| Metric | Rating | Calibration-Standards |

|---|---|---|

| Needle Bar Height | 10.5 mm | Ensure correct alignment and orientation. |

| Looper Clearance | 0.05 mm | Critical for preventing skipped stitches and ensuring proper timing. |

| Differential Feed | 0.5 - 2.0 | Adjust for even fabric feeding and stitch consistency. |

| Maximum Speed | 1400 RPM | Achieved with "Hare" setting on speed control. |

| Minimum Speed | 650 RPM | Achieved with "Tortoise" setting on speed control. |

| Fuse Rating | 3.15A/250V | Specific type for 230V; slow type T for 100-120V. |

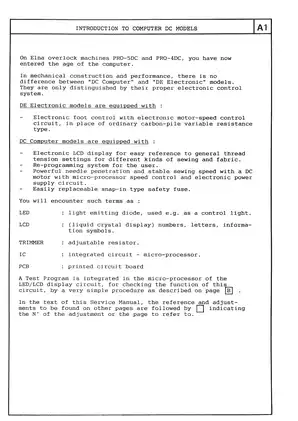

Technical content addresses maintenance, adjustments, troubleshooting, and technical modifications for the Elna Lock PRO series. This manual provides detailed insights into mechanical and electrical systems. It includes procedures for setting tensions, timing various components, and performing electrical diagnostics. The document serves as a primary resource for technicians and advanced users. The manual covers adjustments for all primary sewing mechanisms, ensuring proper stitch formation and machine longevity. It also details diagnostic routines for electronic control units and troubleshooting common issues. Professional repair and maintenance are facilitated through clear instructions and diagrams. This document aims to guide users through complex procedures with clarity and precision. Torque specifications are documented for gasket seal integrity. Parts identification is covered for all major assemblies and sub-components. Removal procedures are documented for all major components to facilitate repair. Factory specifications are documented for all adjustable parameters to ensure optimal machine performance.

FAQ

Customer Reviews

Read what our customers say about this Elna Sewing Machine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)