Lexmark C750 Color Printer Service Manual 5060-001/002/003 (264 P.)

Factory documentation for Lexmark C750 Color Printer addressing fuser assemblies, ITU belt systems, and HVPS diagnostics with complete parts catalog and connector pinouts.

Manual Preview

Sample pages from the Lexmark C750 Color Printer Service Manual 5060-001/002/003 (264 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Lexmark C750 Color Printer (5060-001, 5060-002, 5060-003) — 1996–2005 Original Certified Dossier | C750 Series Package.

- Engineered Power Framework: 20 pages per minute (ppm) is set to support both four-color and monochrome print jobs across all color modes Mapping.

- Defined Operating Temps: For optimal operation, 15–35°C (59–95°F) reaches the environmental limit Configuration.

- Standard Cycle Rate: ITU Assembly replacement is standardized to 105,000 copies when "83 ITU Maintenance" displays Benchmarks.

- Principal Package Size: The 42-inch model corresponds to 54.5 kg (120 lb) maximum unit weight Range.

- Advanced Moment Values: Fuser lamp specifications yield 115V 500W Hot Roll and 220V 500W Hot Roll assemblies Sequences.

- Primary Current Rating: Maximum addressable print output is established at 1200 dpi resolution Baseline.

Professional Workshop Service Manual & Technical Specifications

Commercial Electrical Manual: Lexmark C750 Color Printer Service Manual (5060-001/002/003) (264 P.) Procedure-Database

Architecture-Focus: 5060-001, 5060-002, 5060-003 // Calibration-Scope: Color Laser / Electrophotographic Logic // Architecture-Focus: 1200 dpi CMYK imaging path with thermal management protocol.

| Document Contents | Value | Coverage Reference |

|---|---|---|

| Service Procedures | 264 pages | Complete specifications provided |

| Chapter Modules | 7 primary sections | Documented across assemblies |

| Component Assemblies | 18 illustrated groups | See Chapter 7 Parts Catalog |

| Diagnostic Protocols | 43 procedures | Diagnostic Information complete |

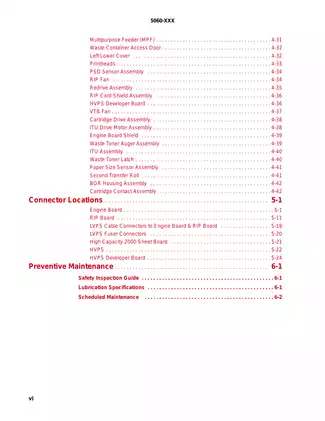

| Connector Specifications | 5 board locations | Pin-level documentation |

| Error Code Database | 9xx/1xx series | Sub-error indexing included |

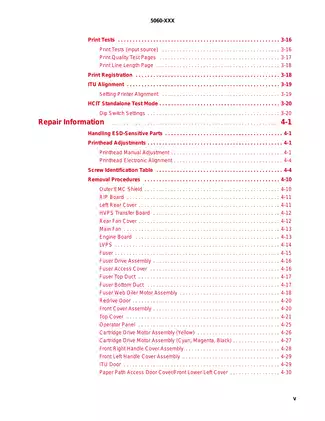

Following OEM groupings, the manual includes Notices and Safety Information addressing laser compliance protocols, presents General Information detailing service tools and acronyms, documents Diagnostic Information with symptom isolation tables, covers Diagnostic Aids featuring hardware validation tests, and addresses Repair Information including printhead alignment sequences.

Professionally requiring maintenance intervals at 105K-copy ITU replacement cycles and 150K-copy fuser assembly service points, the documentation addresses electrophotographic imaging architecture across four CMYK printheads operating at 1200 dpi addressable resolution. Comprehensive schematic coverage details the vacuum belt transport assembly coordinating media advancement through registration sensors S1 and S2, while thermal control specifications define dual-lamp fuser configurations supporting 115V 500W hot roll and 220V 500W backup roll assemblies with integrated thermistor monitoring networks.

Assembly instructions are detailed for cartridge drive motor systems utilizing brushless DC servo control across Yellow, Magenta, Cyan, and Black stations, each requiring automated motor detection protocol following replacement procedures. The documentation addresses seventeen connector locations spanning Engine Board J-series terminals, RIP Board interface architecture, and HVPS developer board control networks, with pin-level voltage specifications documented for +3.3V, +5V, and +24V distribution rails.

System operation descriptions cover ITU belt transport mechanisms driven through indexed zone clock signals, fuser cam positioning validation via dual-sensor feedback, and autocompensator pick assembly actuation synchronized to staging motor encoder sequences. Wear limits are specified for vacuum transport belts, second transfer roll contact pressure maintenance, and paper path sensor flag tolerances across multipurpose feeder and integrated tray assemblies.

Disassembly instructions are documented for field-replaceable units including outer EMC shield removal sequences, RIP board extraction requiring USB connector detachment, and HVPS transfer board isolation involving spade terminal disconnection from transformer outputs. The manual documents torque specifications for printhead mounting screws to ensure proper optical alignment retention during M3x6mm Taptite fastener installation across laser scanning assemblies.

FAQ

Customer Reviews

Read what our customers say about this Lexmark Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)